Reply to edb:

Hi Gary,

it should be a light interference fit on the shaft flange to maintain concentricity.

You may need to close the coupling back up again as I could see that the splay of the coupling splines would interfere --be bigger than --the drum bore.

Hope this helps.

Cheers,

Eddie B.

[quote="edb"]Hi Gary,

it should be a light interference fit on the shaft flange to maintain concentricity.

You may need to close the coupling back up again as I could see that the splay of the coupling splines would interfere --be bigger than --the drum bore.

Hope this helps.

Cheers,

Eddie B.[/quote]

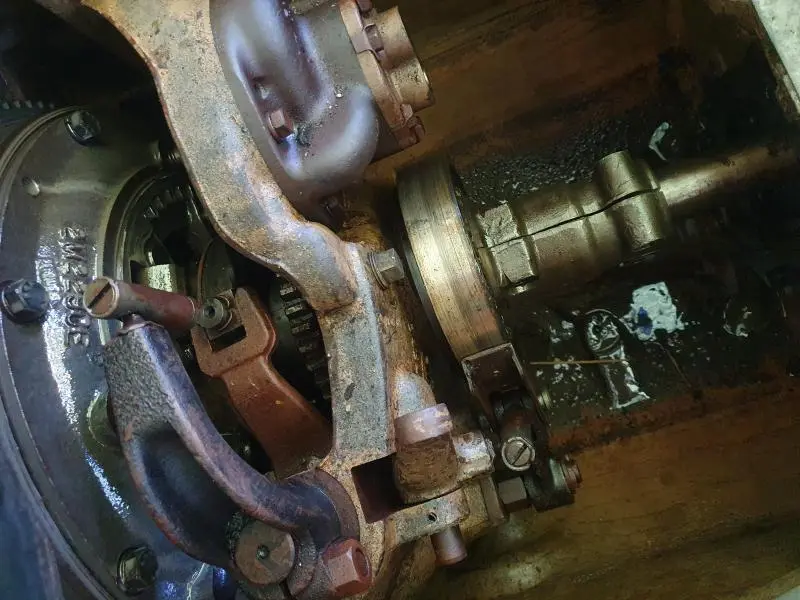

Have pulled engine out managed to get the drum to slide over the coupling splines as we moved it out. Drum is solid on flange, maybe some corrosion as rest of tractor is in poor state and gearbox and winch were full of grey gunge.

Any idea of how to find serial number?, plates on engine, dash and transmission case all missing. Number 9H5822 stamped on transmission case under where serial number plate would have been, guess this is a casting number?