Reply to td-alan:

Thanks but still looking for the specification for the D4600 4.25 inch bore . I have new liners and new copper seals that go under the liner in the counterbore , the block is completely disassembled and headed to the machine shop for a light surfacing and I want to make sure that with all of the parts that I have that we can obtain the correct amount of protrusion, the only mention of liner protrusion is in the caterpillar serviceman’s guide for the D6 4R /5r tractor and it only mentions that they should “extend slightly above the face of the cylinder block “ . I assume that the D4 4g with the D4400 would be the same as the D4600.

Hi Team,

Alan,

the statement that the liners should "extend slightly above the block face" is the only spec. that I recall I ever saw at The Dealers back in the early 1960's when I started my Apprenticeship.

I do not recall if there were actual dimensional values given for the then new D300 series engines in the early 1960's.

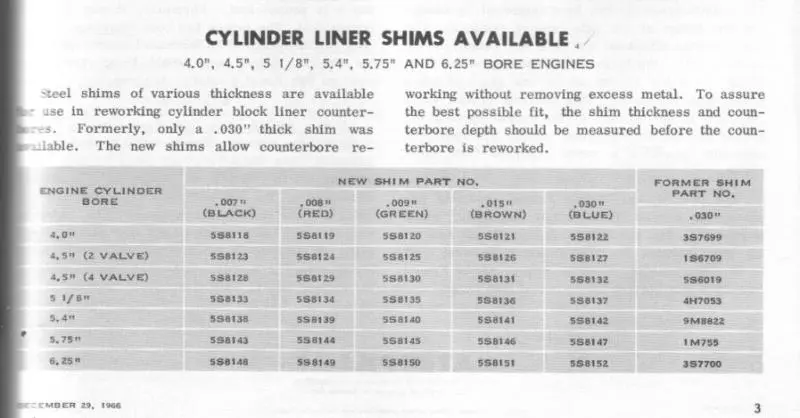

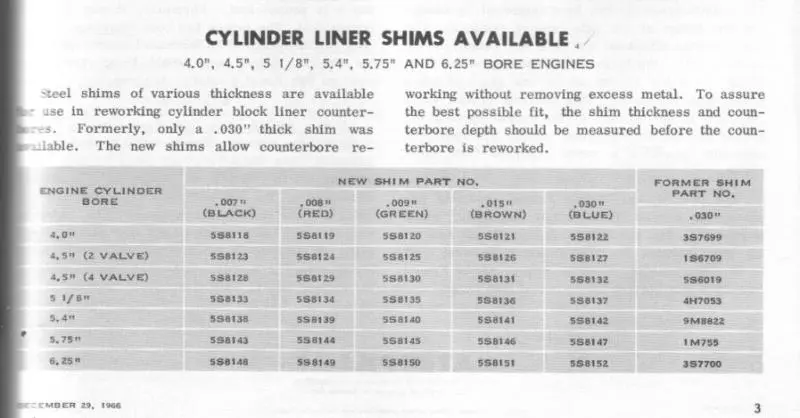

I feel it was around the mid to late 1960's that I seem to recall shims being available in the Cat system.

I guess it was around this time that actual specifications for protrusion were published--I stand to be corrected.

Before shims became available in the Cat system I seem to recall early/any engines that required counter bore seat deepening due to fretting, corrosion, & etc., necessitated in us having to have special thickness copper shims being made locally.

The attachments I gave previous were to give you possible Part Numbers for shims taken from a --I think Service Magazine-- and from a Service Manual, a full description of the method we used to clamp the liners for accurate measuring--even though the method is from a much later series of engine family, the method and dimensions still holds true.

Cheers,

Eddie B.