I would think trying to out engineer CAT would be very foolish, If the D4400 didn't need the lower oil ring it would not be there. I would check the ring end gap and other spes of the bore and piston. It takes very little oil to lub the piston in the bore. It would be quite the experiment to leave it out, only to tear the engine down to put them back...My 2 cents...WA7OPY

I have no experience with one, but you do have plenty of rings left above the piston pin. You would not be down to 3208 configuration with 2........count them.....2 rings. I will grant the 3208 wasn't famous for longevity!

But a D4400 doesnt run 2500 rpm!

I could be that the lower ring might hold the oil between the two rings with the wrist-pin supplying oil between them with leakage from the bearing fit of the piston. I am sure Cat done a lot of r/d before the D4400 was put out to production. Or it might not be necessary with modern oils, I used both oil control rings in mine engine, and I have seen two oil rings used in many older diesel engines....WA7OPY

Could you post a closeup picture of the Hastings and CAT rings and how you plan to install them?

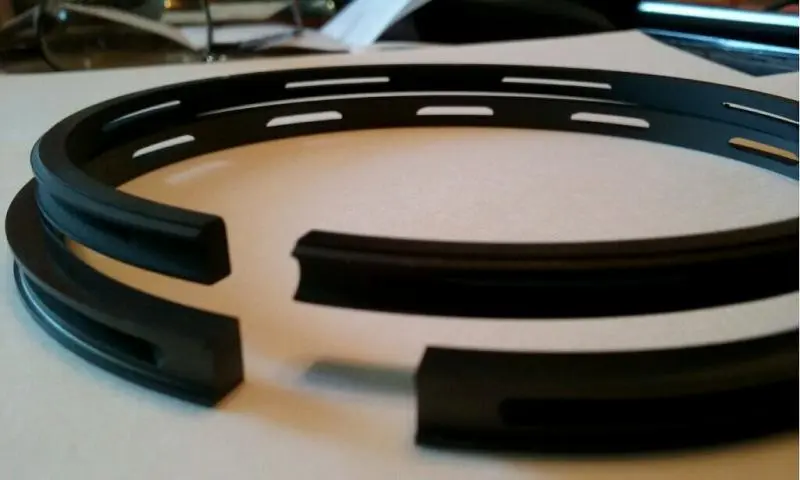

If I understand you correctly, the Hastings oil control rings are solid rings but with the top edge radiused so it scrapes oil mostly on the down stroke? Or maybe it is a conventional modern oil control ring with a spring expander and a channel between top and bottom edges?

Here are photos of the different rings. Hastings has an expander. Radius is on both sides, Cat has square edges. Chad Enyeart in Laramie leaves out the bottom ring with no problem, based on an old service letter he remembers. Chad restores old Cat machines. So I'm just going to leave out the lower ring and use the Cat ring for upper. Note I see photos are poor quality. Will get better ones.