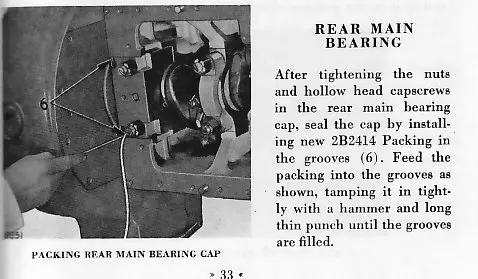

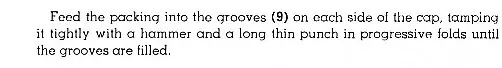

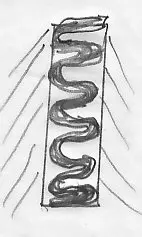

That packing is just a roll of special string and you can get it at your Cat dealer and is reasonable. The number is 2B2414 so I have put it in 100s of engines at the dealer and I always cut about a 6" piece and would drive it in tight and then cut another piece till I had enough to fill each channel. The reason for no lip seal is the crank shaft back in that area on most all the older Cat engines had reverse threads on the crank end on the rear section of the journal and it screwed the oil back into the oil pan.You,ll need a thin long narrow punch or I used a piece of welding rod to pound the cord down in the groove in the cap.The way I put the cord in was lap it back and forth as I forced it down in the groove.

Hi 2U,

here is a rough diagram to show what SJ is talking about as to the lay-in method. You need to tamp each loop to get the most efficient density of the seal chord. Any loose areas wil possibly leak engine oil out into the flywheel housing. Aim for the packing to be about 0.010" - 0.015" proud so as the gasket will keep it compacted when the sump is installed.

cheers,

Eddie B.