Hi Mike,

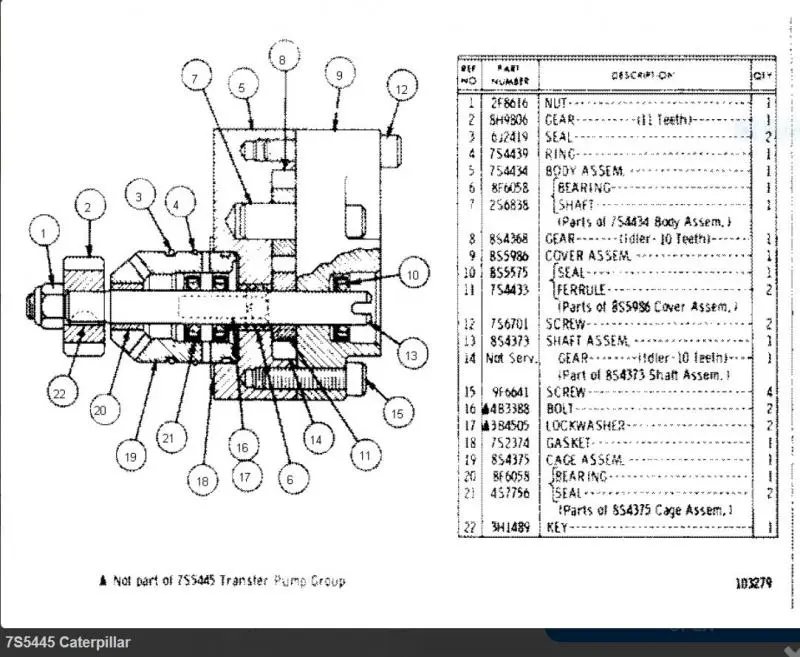

Here is the updated numbers,

[attachment=59947]Screenshot_20200805-200827_Chrome.jpg[/attachment]

Regards

Morning Daryl, thanks for those numbers, I wonder why my search at Cat Parts Store did not offer any part options at all for both?

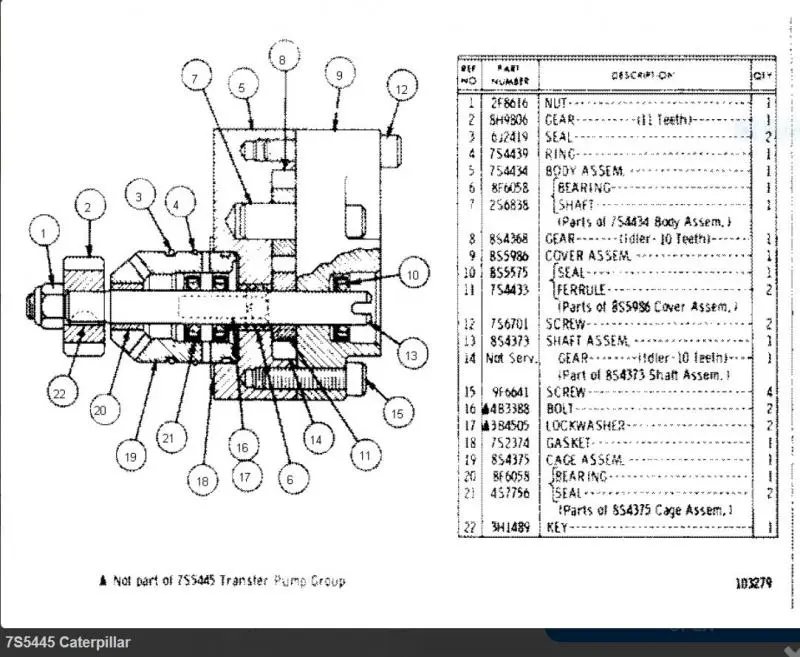

So that small one piece gasket on the transfer pump face, has become 2 gaskets and a seal, is that correct?

Thanks

Mike

Got the new Cat parts in the mail, unfortunately that new gasket number is not the correct part for my pump, not even close to being right, so I'll need to make one, no biggy, interestingly I must of had the same issue 8 years ago when we worked on that transfer pump, because in my parts box for the D4 I found the exact same new gasket, that obviously I'd bought, and hadn't used.

Edb or Old Magnet, that small gasket 2A3862 (now 6H9949) that sits in under the fuel transfer pump "Seat" 3B4749, is there any reason why I couldn't use a suitable sized O ring there, that would crush to the right thickness, instead of cutting that skinny little paper gasket to fit it in under the seat. I really do not want to risk upsetting the new pump shaft seals pulling the transfer pump shaft out simply to fit that small gasket, if I can possibly avoid it.

Eddie, I know you mentioned having previously cut a gasket like that one at 45 degrees to slip it into place, then glued it closed again, I assume using something like super glue?

Thanks

Mike

The o-rings/seals used are not common trade size o-rings. I can furnish dimensions if needed.

The 4B5098 gasket is still a good number, maybe try after market for the one piece version.

Common to see them split to avoid messing with the packing arrangement, just use a dab of aviation gasket cement to reseal the cut joint. I don't think substituting an o-ring is a good idea.

Thanks Pete, appreciate your thoughts, I'll make a new gasket and create a seam that allows it to slip over, then under the seat, as you suggest. In case anyone is wondering, the "seat" in the photo is a spare I have here.

I was thinking about using a O ring after seeing them in my #41 hydraulic pump, figuring if they can handle that purpose, they should handle a low pressure situation.

Those new shaft seals are very easy to damage, I remember all too well the challenges I faced the last time I repaired this transfer pump, luckily Eddie B stepped in and helped overcome the obstacles, but I'd very much prefer not dismantling it again.

Regards

Mike

If your faced with having to repack again might consider going to lip seals like later pumps. Modest machine work required.

Interesting thought Pete, I'd never considered that, or knew that Cat had moved away from those graphite soaked, wedge style seals.

Thanks

Mike

Late pump example...

Seal conversion was a service by Bill Walter along with injector testing and refurbishment.

I don't know that anyone in the club has taken up the operation.