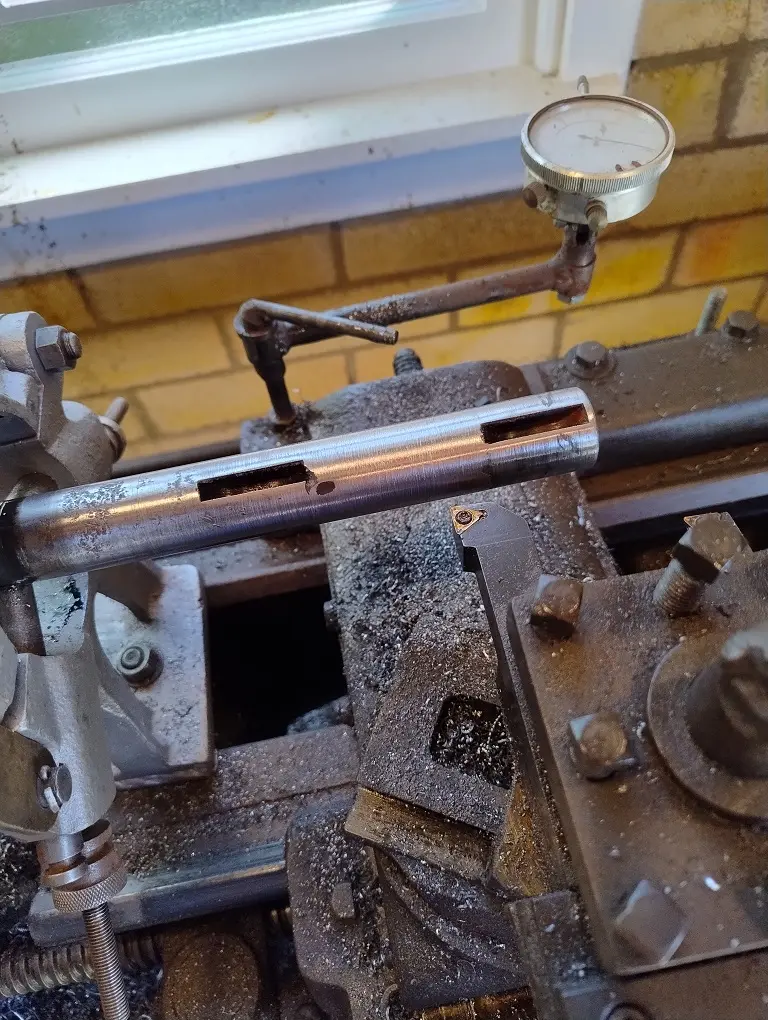

I've made new shafts and bushings for a few of my D2's and D4's. Gotta orient the woodruff keyways correctly on some of them. Looks like it didn't wallow out the clutch cover casting. I had that before and had to bore the casting true before pressing in new oversize or custom bushing. Check the bushing in the bottom of the clutch compartment too. It may be worn but not as bad as the top one.

Soo Nice having a clutch mechanism that has no play!

110% agree with side-seat - the improvement in operability and adjustability with slop removed from the linkage is quite possibly the best outcome from the refurbishment of my 5U - the clutch operates with a clean, precise, and minimal operator movement and effort. The new brakes and steering just makes the whole tractor a joy to operate. By comparison, my buddy's HT4 is at the other end of the spectrum and it's hard work, inefficient to operate, and almost impossible to adjust to a stable, usable condition. We're definitely doing steering and brakes in that unit