You can check some things on the bench such as spray pattern and dribble if you have an injection tester. You could also check basic pump operation and configuration first. If you pull the exhaust manifold off or use a stethoscope, you can check which cylinder is missing, then move the injectors and pumps separately to isolate the cylinder.

You can fit new nozzles to the injectors - they're under $20 each from your dealer so that's an easy step. To move injectors / replace tips, you'll need the injector nut removal tools and a set of o-rings. Be prepared for the possibility of needing to replace some precombustion chambers, and maybe have someone tee'd up to send you an injector or two if it's determined you need them.

D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

you can remove the injector and injection line. turn the line to the outside reinstall the injector onto the line and then use the pony engine to turn the big engine while you observe the injector for malfunction.

Like this ole timer at 6:40

https://youtu.be/9m43V7M2rTE

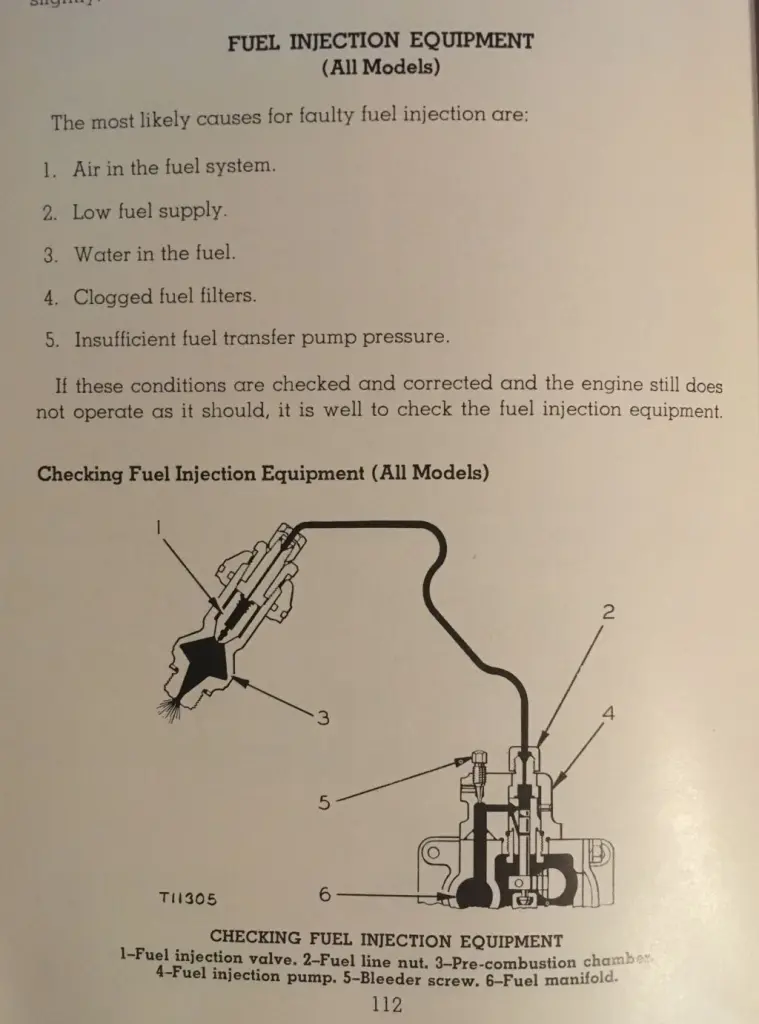

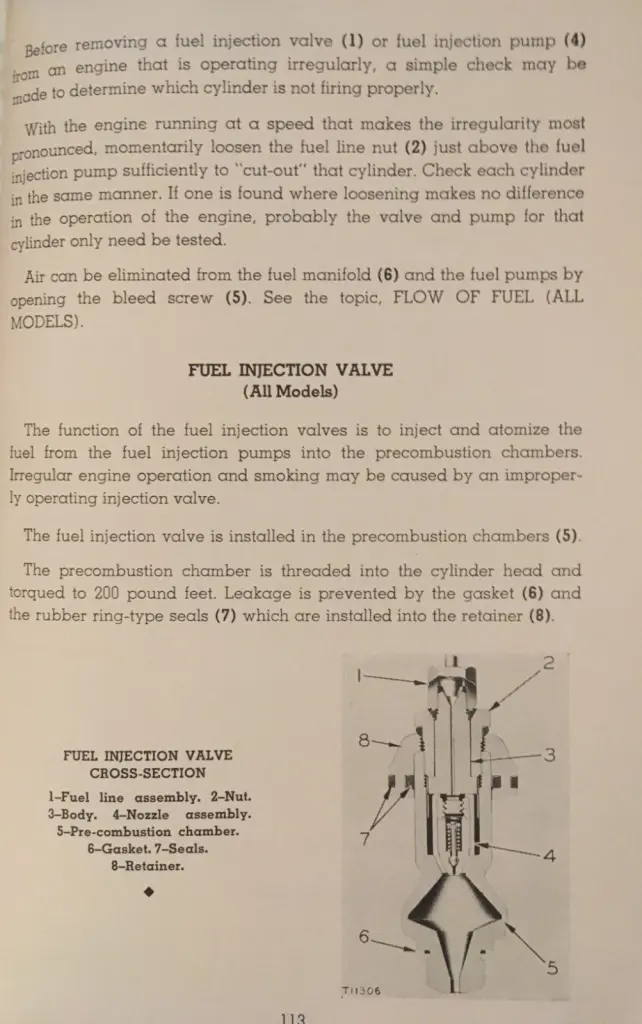

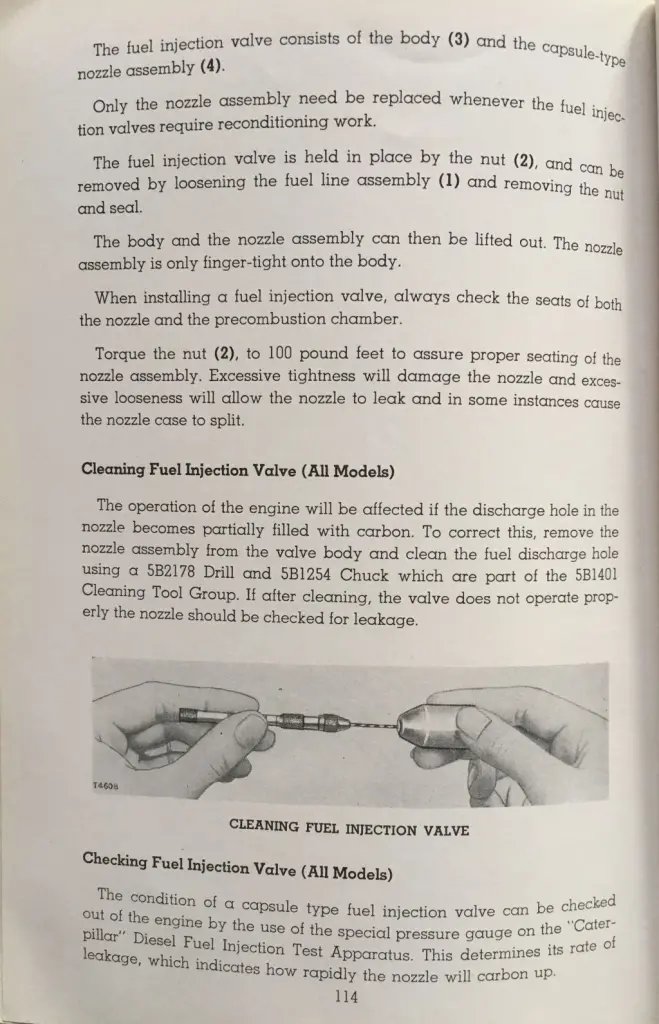

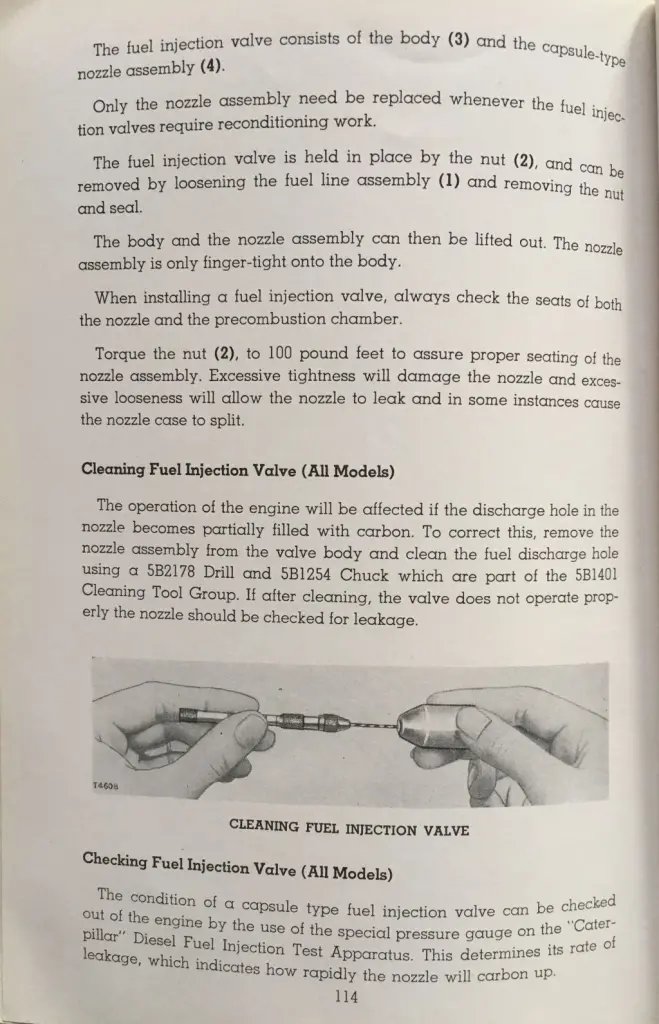

Here are the pages from the service manual for the D315 engine in your tractor.

Heat gun on the exhaust manifold will often show a cooler temperature for the offending cylinder. Very easy initial check no dismantling required.

Hey Gary-

I’ve watched the video three times. Great info-another useful resource you’ve shared. Thanks!

Cheers-

Bernie