Hi,

without the knowledge and tooling I would simply measure the placement of the old lock nuts in reference to the connector bar slot and refit them to the new bar using the previous nut position measurement as a reference.

Cheers,

Eddie B.

Thank for getting back but locknut and adjusting nut came lose and backed off. Now I need to know how to readjust it

Hi Team,

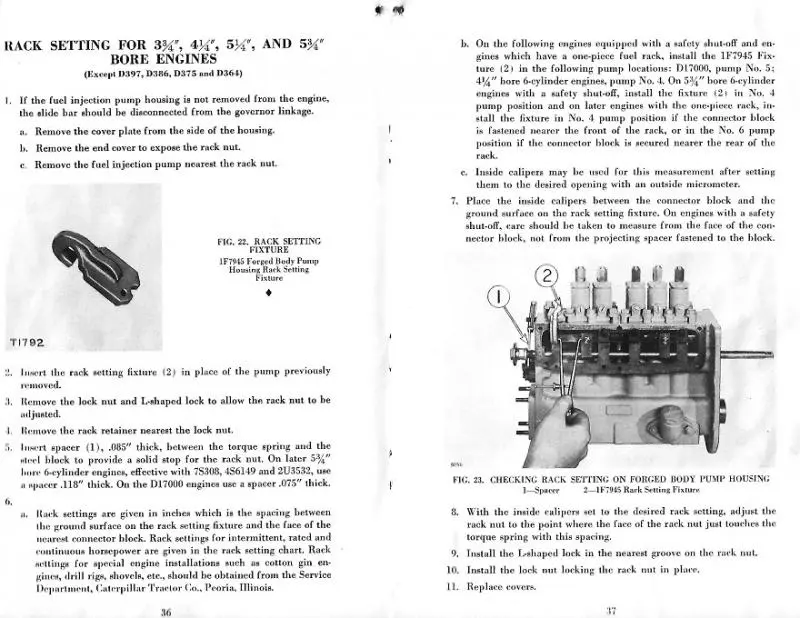

scan tells how to do this procedure.

Special tool is needed.

Please understand that at this point we cannot help you further until we know the Application, Horsepower, or Speed Ratings for the engine.

If it is in a D2 it will have a different rack setting and speed rating to D3400 Industrial engine, Gen Set, Marine Engine, Drag Line Water Pump and so on.

Might it be possible for some one to measure from the nut face to the front edge of the rack linking bar on an engine in similar application as yours [i]when we know what it is.

[/i]

This was rocket science back in the day and Cat still keep all this info close to their chests--in the very beginning of Cat's entry into Diesel engines only The Cat Factory Engineers were capable of and had the tooling and knowledge of working on this area.

Sorry, for the moment I cannot help further at this point without further information from you.

Best Regards,

Eddie B.

D2. 5j. Crawler.

Hi Team,

rack setting for a D2 5J is given as 3.010" using the tooling shown in scan post # 4,

Engine develops 32 Belt HP, @ 1525 RPM Full Load Speed.

High Idle Speed is given as 1650 RPM.

Low Idle Speed is given as 600RPM.

Rack Setting if checked with the 3H1690 Rack setting tooling is given as 0.460" and the scans below show how to use this tooling.

This what we used at The Dealer for Forged Body Injection Pump Rack setting. Now you need to get friendly with someone who has one of these.

Hope this helps.

Cheers,

Eddie B.

Anyone know the measurement from the locknut to the end of the bar

Hi Team,

rack setting for a D2 5J is given as 3.010" using the tooling shown in scan post # 4,

Engine develops 32 Belt HP, @ 1525 RPM Full Load Speed.

High Idle Speed is given as 1650 RPM.

Low Idle Speed is given as 600RPM.

Rack Setting if checked with the 3H1690 Rack setting tooling is given as 0.460" and the scans below show how to use this tooling.

This what we used at The Dealer for Forged Body Injection Pump Rack setting. Now you need to get friendly with someone who has one of these.

Hope this helps.

Cheers,

Eddie B.

Eddie, would you be able to repost the scans? For some reason I cannot see them.