Going to take a heavy duty ridge reamer with tungsten carbide blade to get the job done.

Hi Phil,

bit rushed at present after 3 day Rally and yet to unload.

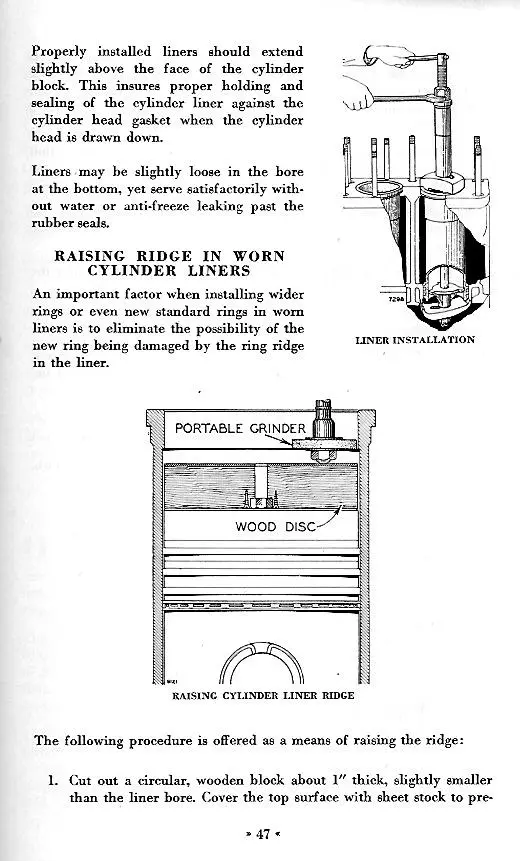

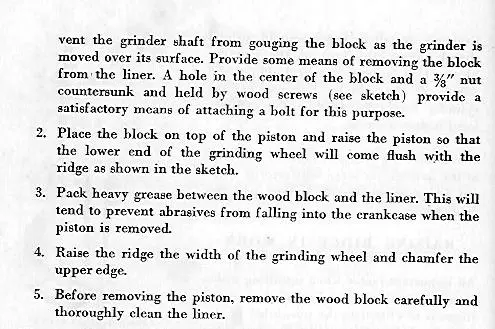

Posted on this recently so hope the link works for you to find the rough and ready method suggested in older Yellow Servicemen's Reference Books--this one from a D6 Tractor Book, Form No 7861-A, Dated 1-44.

Maybe set up the liner in a lathe and using a tool post mounted die grinder the ridge could be raised.

http://www.acmoc.org/bb/showthread.php?31541-R2-4J-sleeves(liners0/page3&highlight=liner

Hope it helps.

Cheers Eddie B.

OM

I have a Lisle Ridge remover that has a tungsten carbide cutter but it won't remove the ridge. It simply rides up over it.

Eddie

Thanks for that info. If it's good enough for Cat then it's good enough for me😊 I will give it a try tomorrow. As the ridge is very small I might use a rubber sanding band rather than a grinding wheel but I like the method of stopping the wheel going too deep.

Regards

Phil

I suspect the Lisle reamer is not ridged enough and the cutter possibly not sharp enough. The Cat ridge remover uses a carbide cutter but it is mounted in a really heavy duty holder.

Hello OM

I think you are right. The ridge remover shown in the manual is an entirely different style to the lisle version. The lisle version locks up inside the bore and the cutter is spring mounted. Do you know the part number for the Cat ridge remover?

Regards

Phil

The liner ridge tool group for 4-1/4 and 4-1/2 " bore is 3F960.

For some reason even though my tool listing is dated 1970 it skips over the D330C 4-3/4" bore.

Hi Team,

the ridge raiser tooling was used before the D300 series engines were designed and had fallen out of use by then.

For small ridging we used to use a Flex Hone--bottle brush bauble type, or sent the liners out to be hard honed with a fixed stone type hone in a hydraulic honing machine--only good for small wear and done to about a 80% cleanup.

Bottle brush type rounds off the edge of the ridge so hopefully the new rings do not catch on the rounded ridge and fracture the top ring and/or ring land in time.

Cat liners became so hard that the cutting tools of the day would not last or sometimes not even penetrate the surface to cut away the lip--they also only worked at one level of cut--tool width-- in the liner and so were termed Ridge Raisers as they did not cut the ridge right up and out of the bore as do most automotive tools with a fine threaded tool carrier and frame.

The grinding method given previously is from the D6 Army Technical Manual TM5-3100 as supplied from Caterpillar in the Servicemen's Reference Book for the D6 Tractor, Form No 7861-A, dated 1-44, contained therein.

I have used this method on many of my old engine resto's over the years with success--just need a steady hand.

One type that comes to mind is the blind cylinders from radial aircraft style WW2 Tank engines I had--the ring wear ridge is at the closed or head end of the unit so is a long way down from the opening.

Cheers,

Eddie B.

Hello All

I have given up on the old sleeves. Once I removed the ridge on the first one and checked a ring in the bore there was too much clearance. There is also some pitting in one cylinder from sitting seized for so long. Aftermarket sleeves are only $40 each and they are good enough for the work this loader will be doing.

Regards

Phil