D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

http://www.crowsnest.us/images/DCP_0463.JPG

http://www.crowsnest.us/caterpillar/D318_page_3.htm

here is one that looks exactly like yours. you could always try to contact them since they have done it already

[attachment=66964]74AD324C-7F46-48BB-9727-024A80A39317.jpeg[/attachment]Thank you. Yes whole assembly is captured by 6 cotter pins thru 6 pins that are part of flywheel. The bearings are self aligning double row ball bearings-now skf 2312… cost $500/pop but applied industrial assured me these are not made in the far east

Good choice on the SKF bearings. We use them exclusively where I work and we get up to four times the life out of them compared to other brands with the exception of Timken.

SKF have factories all over the globe including China and Malaysia. Most bearings come from France, England, USA, Germany, Switzerland and Austria. Some of the explorer ball bearings are made in China and Malaysia and a lot of the bearing spacers and taper sleeves as well but I assume you are using spherical roller bearings which are made in Europe mostly.

I'd recommend a shaft to flywheel alignment check in order to get maximum life out of the Thermoid Couplings.

OM has a very good point.

Thanks for that advice. I was thinking of how to check the alignment with any precision… there were shims under the middle bearing which will likely go back where they were. I am going to watch the flywheel pins as they come thru the torque plate rubbers to verify they are centered in the holes. Is there a better procedure for verifying alignment?

Same procedure as the D6 8U/9U with dry clutch....

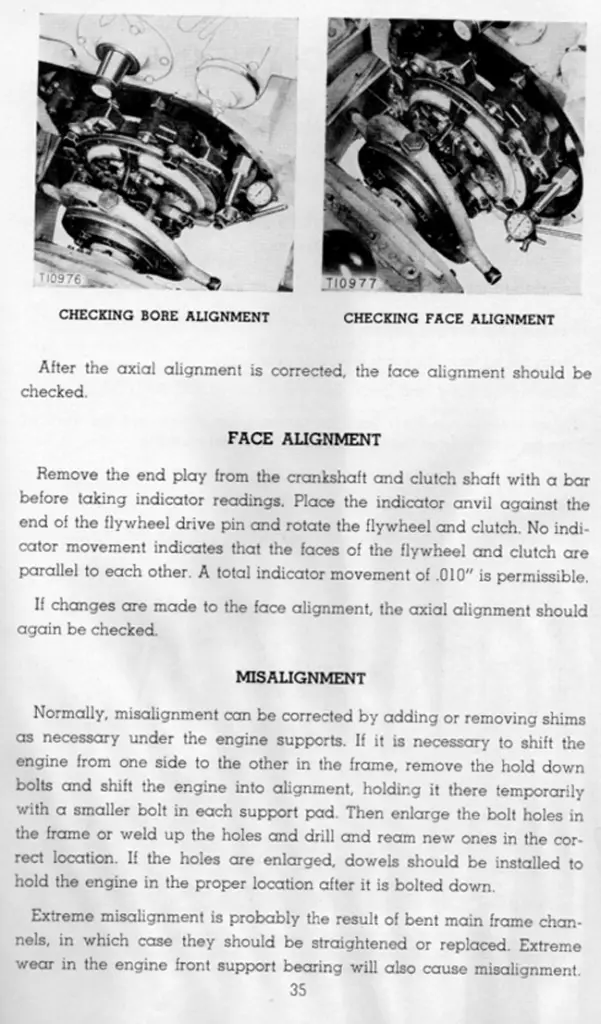

[attachment=66976]D6-Dry-Clutch-Alignment-#1.jpg[/attachment]

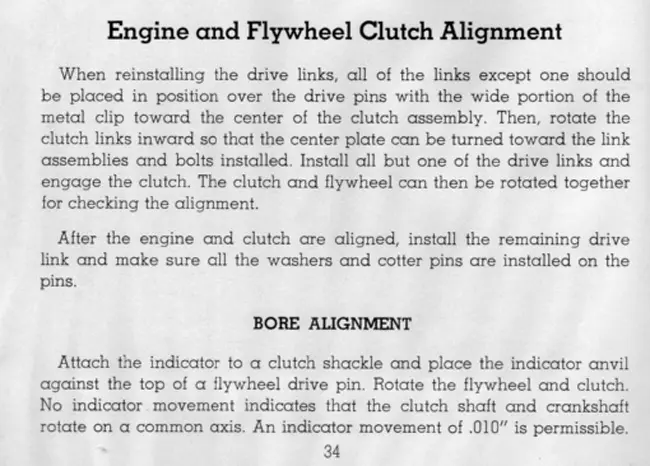

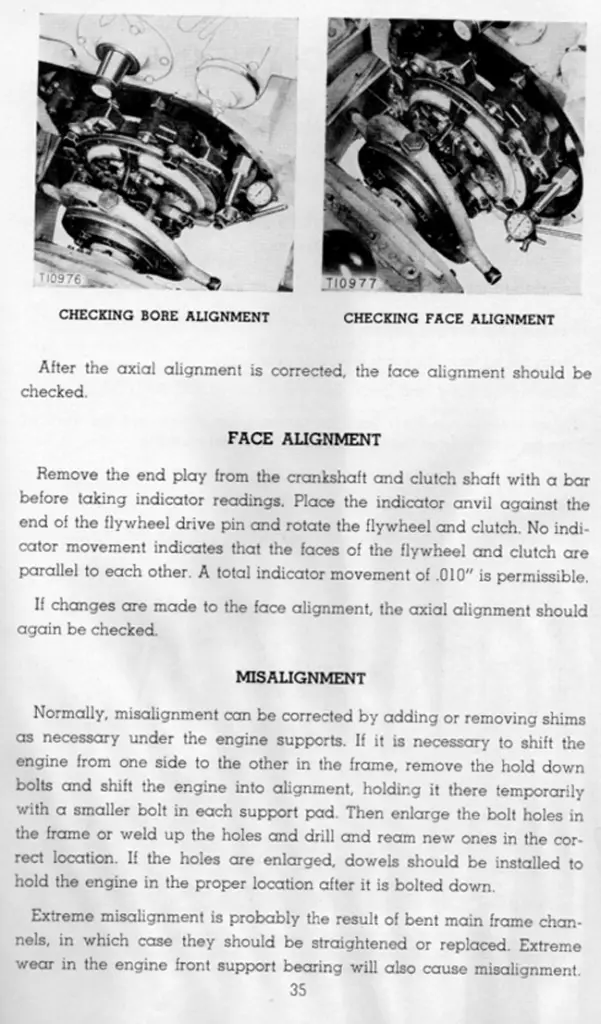

[attachment=66977]D6-Dry-Clutch-Alignment-#2.jpg[/attachment]