First thing I would do is drain a sample of motor oil to check for water or metal flakes etc. Then drain fuel filter and pump it back full of fuel, bleeding air as you go. Most any industrial engine is going to have a bypass valve connected to a return to the tank which should set fuel pressure and purge any air. Sometimes pumping up the fuel pressure will reset the engine safety shutdown system and lock the rack in shutoff. The D330c powered set I had, you would hear the shutdown solenoid make a loud CLUCK WHEN this happened. There should be a reset button that would be held in or pushed in to latch before cranking to release the rack for starting

Then remove air filter pre cleaner assembly to have a flat opening to apply a small board, sturdy book etc in case the engine runs away when you start it. It's going to go straight to 1830-1860 rpm when you start it, but if it takes off for real you can quickly smother it if you are prepared.

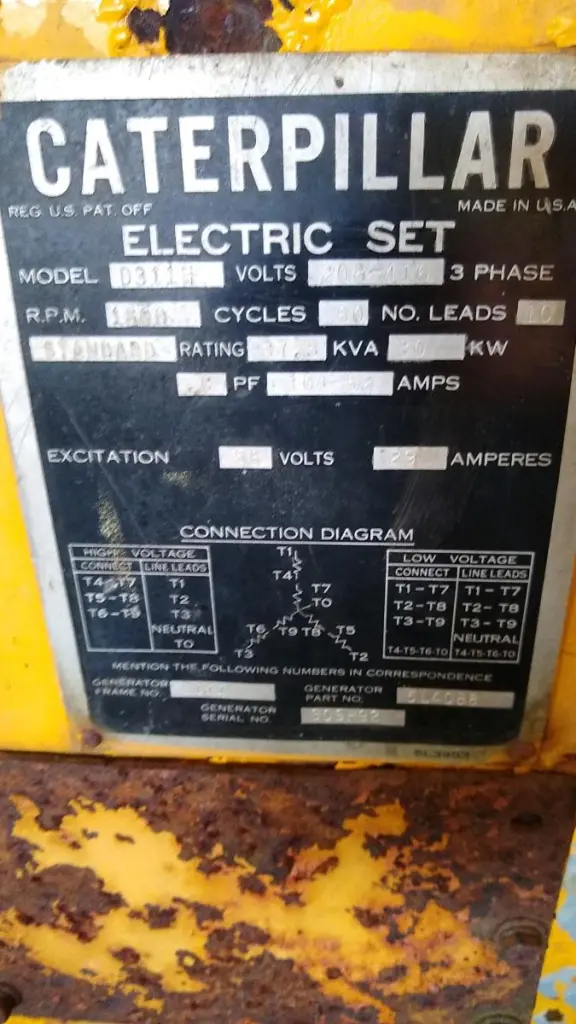

On the generator, at least go into the connection box and look for bare wires that need taping up as well as determining what voltage it is connected for, it's connected correctly etc. If there is an exciter breaker that can be turned off or fuses that can be removed to prevent the generator building up voltage, it might be a good idea to do that until you get the engine sorted out. Be aware that the generator may build some voltage from the "residual" magnetic field remaining in the iron, but more likely this will have to be restored before it will build up even with the exciter enabled. It may have an auto-flash relay on it to do this when it runs up to synchronous rpm.

Finally look for rat nests, mud daubers, snakes etc and listen for scrubbing noises as you crank it over. It would be bad to ruin the rotor field because of a bad bearing etc. I am going to assume it will be a brush type generator since the later one we had was as well. Brushes must be free to move in holders, have good spring pressure holding them against clean sliprings. The rings don't have to be bright brass to work, but if they are, you know that isn't the problem when it won't build up voltage. There are soft stones to hold against the sliprings while the generator is spinning or you can get away with a chunk of Scotch Brite pad in a pinch. Probably best to avoid emery cloth, sand paper etc, but if you do use them, blow all the grit out of the area when you are done. You don't want any imbedded in the brushes or sliprings causing accelerated wear.

D2-5J's, D6-9U's, D318 and D333 power units, 12E-99E grader, 922B & 944A wheel loaders, D330C generator set, DW20 water tanker and a bunch of Jersey cows to take care of in my spare time😄