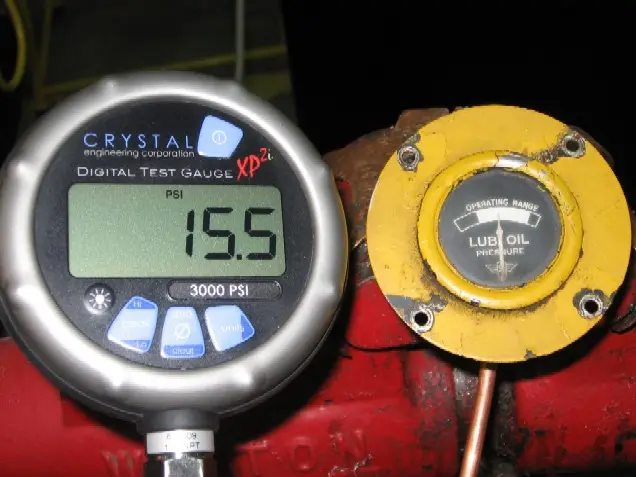

I would think if the screen is clogged, the pressure would be low from the start. One of my D2s pressure is low at idle after it gets hot, but stays well into the safe range when at higher RPMs. Oil pressure comes from the mains, so I guess worse case she's wearing out. Wouldn't hurt though to check the screen, oil filter and such, just to make sure. If you drained the oil, I wonder if you could use a sight mirror accessing through the side plates and see the screen. Rather than dropping the pan. If you remove the pan, might as well pull a couple of main caps and plasti-guage to see the clearances.

I was under the assumption that the oil pump pickup screen could be serviced thru the side plate on the oil pan? Haven't done that yet but that is my plan! :noidea:

I've never done it either. I just happened to have the side plates off my machine this past weekend so I could look at the bottom of the cylinders (inspecting my stuck pistons) and I realize that you can see a lot with those two plates off. I can see some signs of rust at the base of one of the two pistons that are fully down. I suspect that guy is the main reason the engine is stuck.

Hi Team,

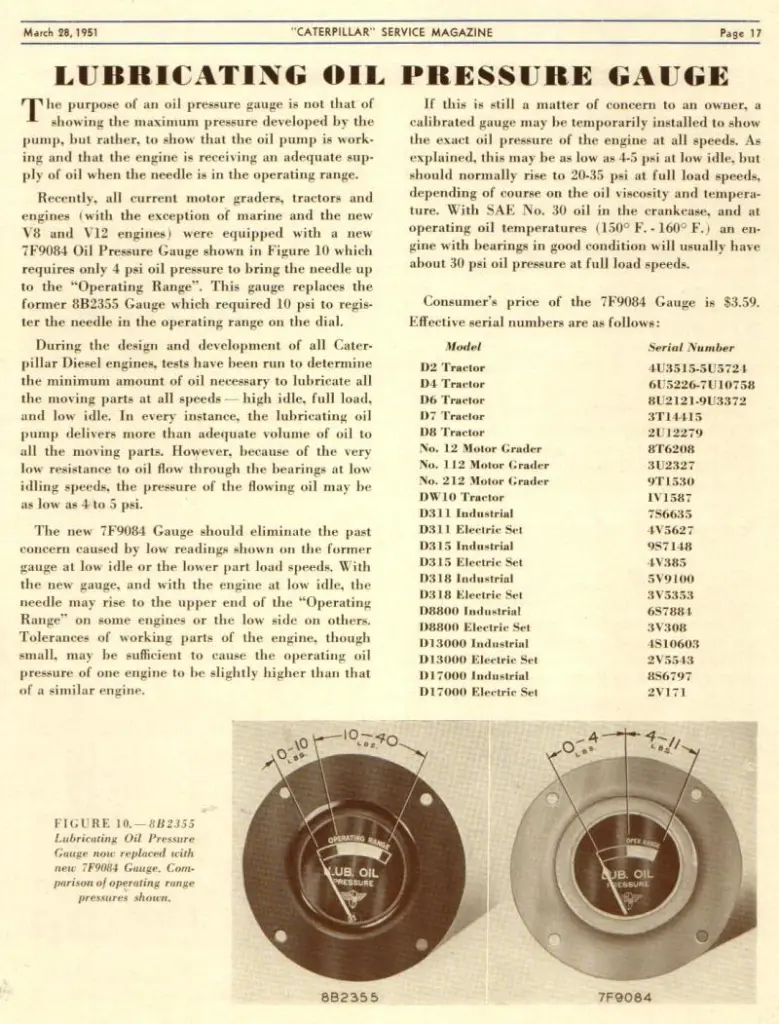

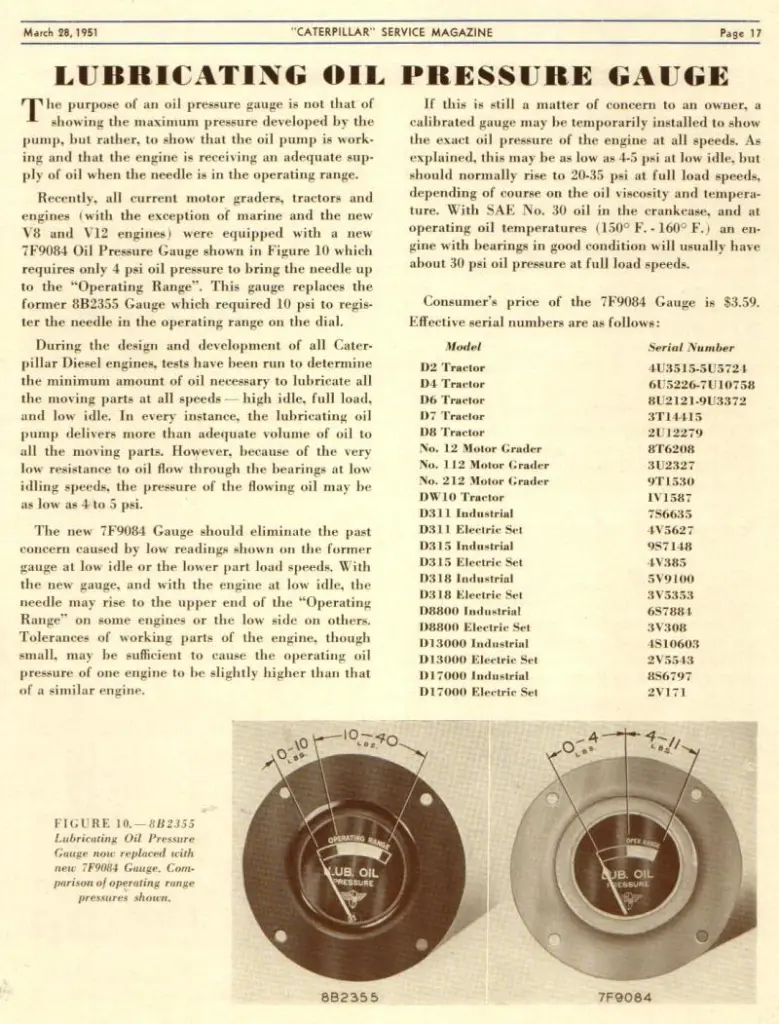

here is a scan about the pressures expected at the start and finish of the White Operating Range of the oil pressure gauges used at the time.

This should set macclar's mind at rest.

Cheers,

Eddie B.

I have always been told that these engines have a rather high volume lubricating system, and lower pressures on the gauge are not necessarily detrimental to the safe operation of the engine.

Here is a quote from my 5U D2 operator's manual-

"OIL PRESSURE GAUGE: Immediately after the engine has started, check the crankcase lubricating oil pressure gauge to see that it is registering pressure. When the engine is running at rated engine speed the gauge should register in the "Operating Range". A lower pressure reading is normal at low idling speeds. If no pressure is indicated, investigate at once."