From what I've seen it's pretty common having weld on the starting engines. Out of the 6 pony motors that I've owned, only 1 has not been welded (that's the one on my "new" D2, 5U9917). If it's not leaking I wouldn't worry about it.👍

As far as your blocked water passage, I'll let the experts chime in.....

Take your finger and slide past that hole, down over the side (J series) there should be a drain plug. Might as well take it out now. Use a coat hanger, to work crud down to that plug or up through the plug hole. Then work it in toward the fourth cylinder also. I found that the bottoms of the cylinders were really full of crud which necessitated the use of a garden hose, an air hose, then a pressure washer before I was convinced that I had a third of the rusty muddy crud out of mine.

When all that was done then I ran a Citric Acid flush through the engine, some guys preferr a stronger acid.

Jeff

thanks i will do some digging as right now water will not evein soak down thought that hole left over 24H that kinda sucks cus my shop has no water and it like 15 out and will be getting colder mabey. i will try shop vac, playing with water dose not sound like fun in the cold.

You could use a dull drill bit as a crud buster, just using it to grind away rust till you hit the casting. Might as well dig around in the pony jacket too as mine was pretty crusty also. The problem is that the water must come up that hole to the pony and out the top. With all the crud in the bottom of the cylinders it'll plug off again and again till you get it all flushed out.

I had the head off from my engine and sleeves out so I waas able to clean mine pretty well as there was about an inch and a half of crud down in there. Then I still acid cleaned it.

Feel your pain with the weather, I hate working in the cold.

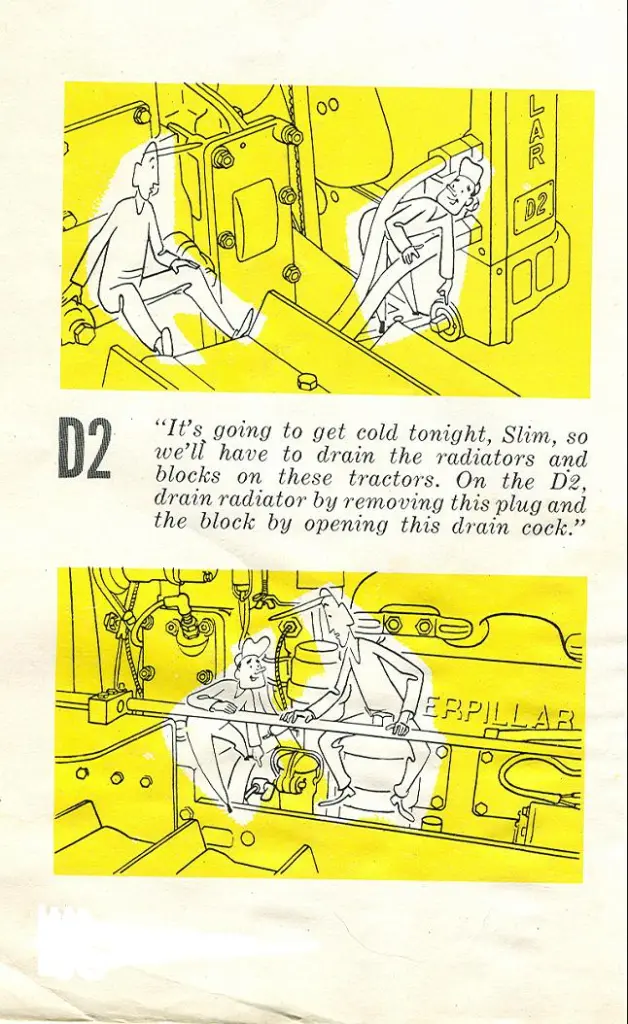

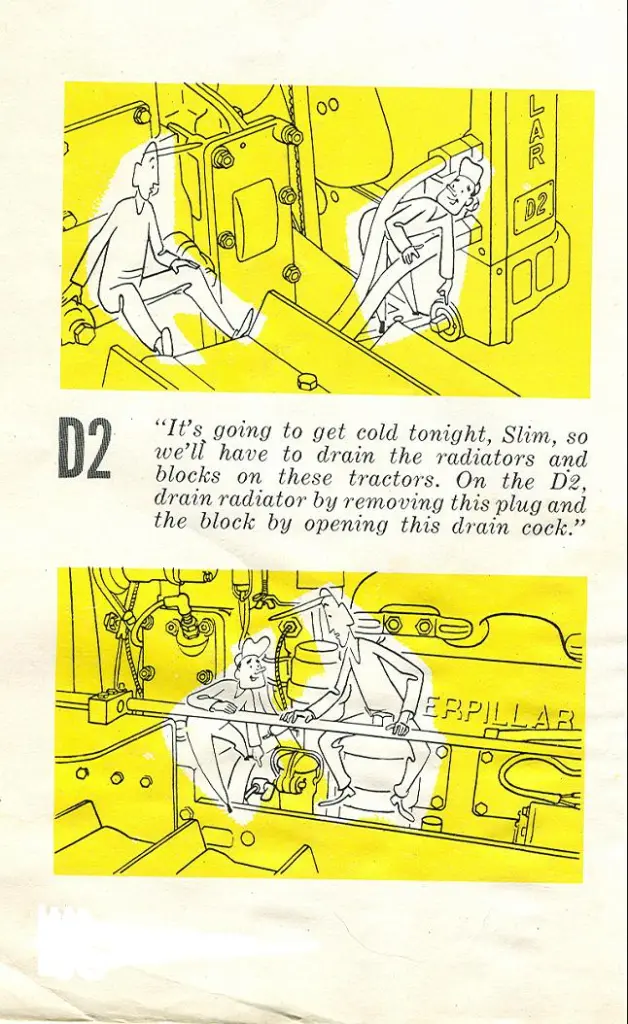

Came across this--Kind of fun--Will help with the need to weld up pony blocks

On my 5J the one behind the oil drain line was a hex plug, so it is hard to tell its there and a pain to remove. I did put a drain cock/valve in it so I can wiggle a wire up there to loosen any precipitated out sediment. I did hook the pressure washer on right there when I was flushing the block to push forward the flush.

Jeff

Something real handy for cleaning the crud out of blocks is a couple of chunks of differing length of old speedometer cable core. Chuck one up in a variable speed drill (on slow to start) and start poking it into the various passages. It'll whip around and do a pretty fair job of loosening the crud. Then as you go deeper, use a longer length.