Not to say you should not seek to get better running gear but by the shape of some undercarriages in Australia that is just run in so for a few hours a year it will probably last quite a while. We have built up rollers with welding in the past, quite a big job to get them out build up and grind off the high spots and refit.

Looks like you have some leaking seals don't run them dry that does not end well.

I replaced my rollers with D3 rollers, they are shorter so I made a spacer bar with 1 1/2 x 2 bar stock, drilled and tapped bar stock then welded bar stock to track frames. If you did the rollers you could get another 20 years out of that machine at the current rate.

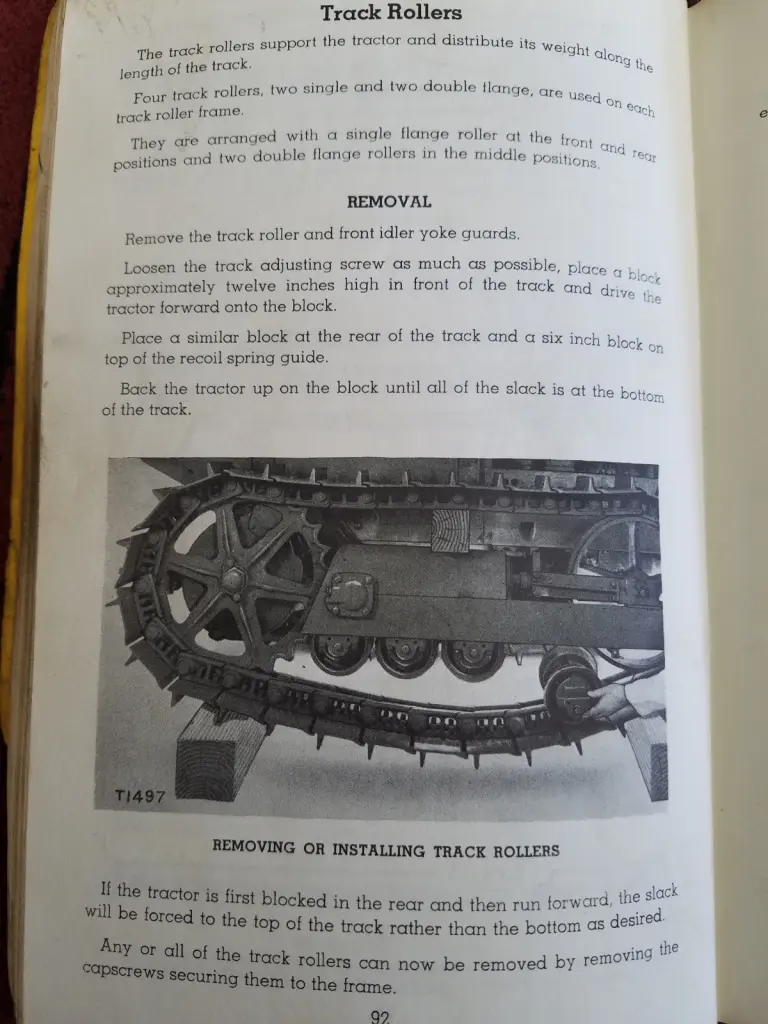

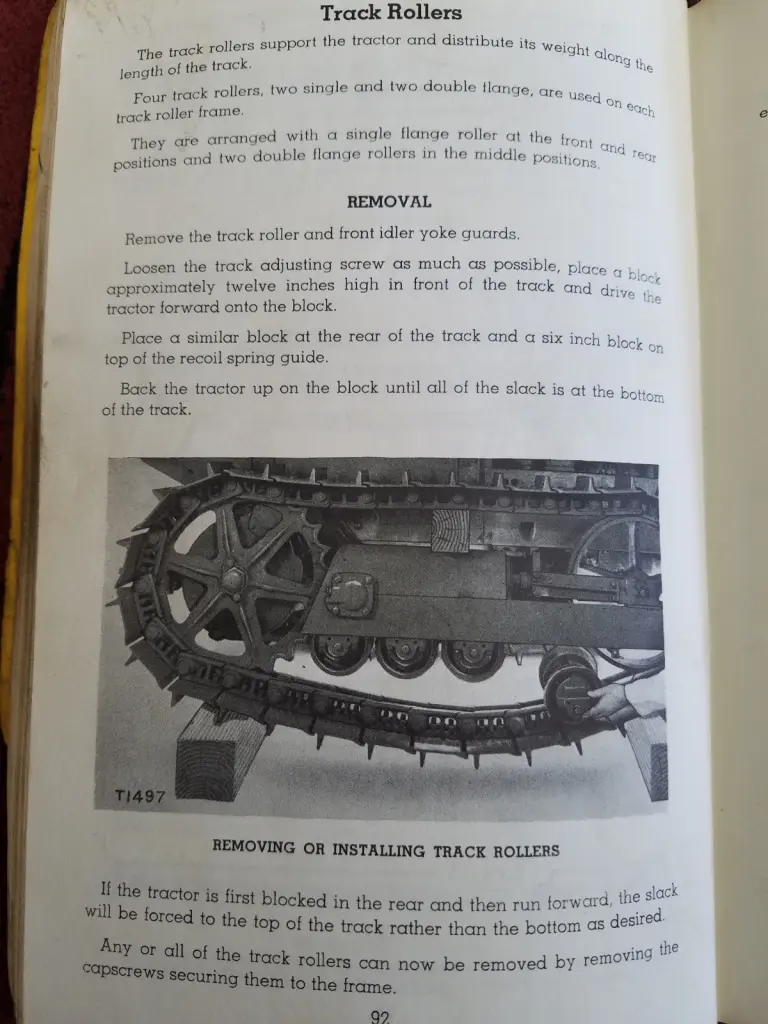

From the servicemens reference book From the servicemens reference book [attachment=62520]20210316_124214.jpg[/attachment]

Cats Forever

I replaced my rollers with D3 rollers, they are shorter so I made a spacer bar with 1 1/2 x 2 bar stock, drilled and tapped bar stock then welded bar stock to track frames. If you did the rollers you could get another 20 years out of that machine at the current rate.