Hey Neil, the tool to hold the spring down can easily be made. I used a bearing splitter and a piece of channel iron for mine but you could just cut a piece of steel and use some clamps to hold it down until the gear is on. I just used an appropriate size deep socket to tamp in the packing. Mine runs in the green with the pony motor and pegs the gauge once the main starts.

Neil go to YouTube and look under D2..3400 Rebuild by Toby Nelson,he will show you how to build the tools quite simple,I did it and it turned out good not to his specifications a bit simpler but works

Hi Team,

cannot get Search to work correctly to link back to many past postings of drawings for the needed tooling and explanations even when using the " " at each end of the wording--it keeps coming back to the main discussion page index for today.

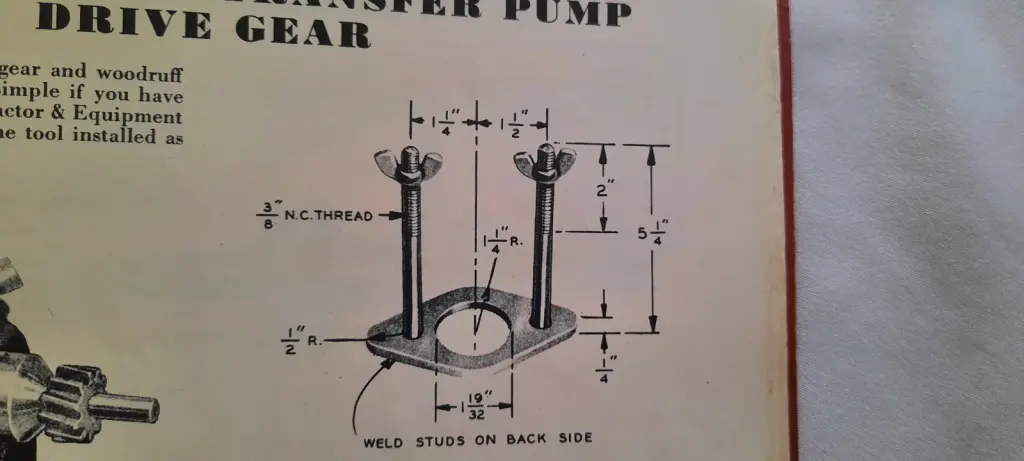

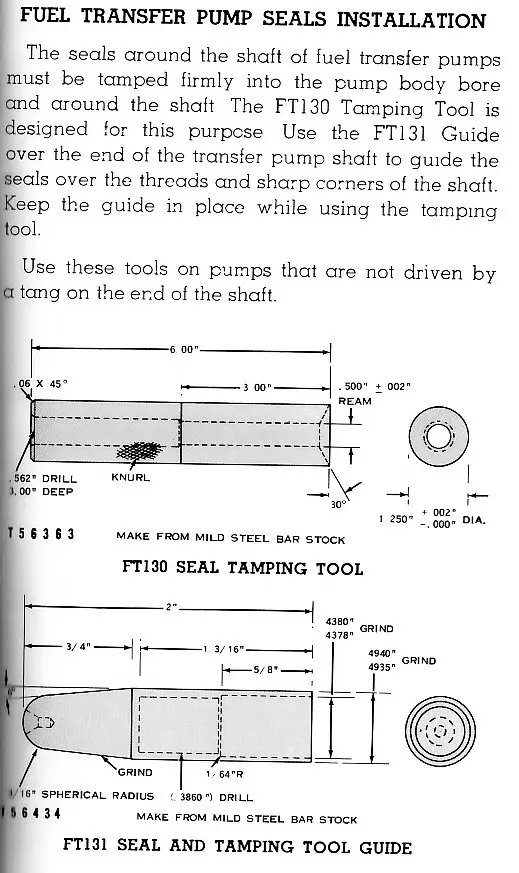

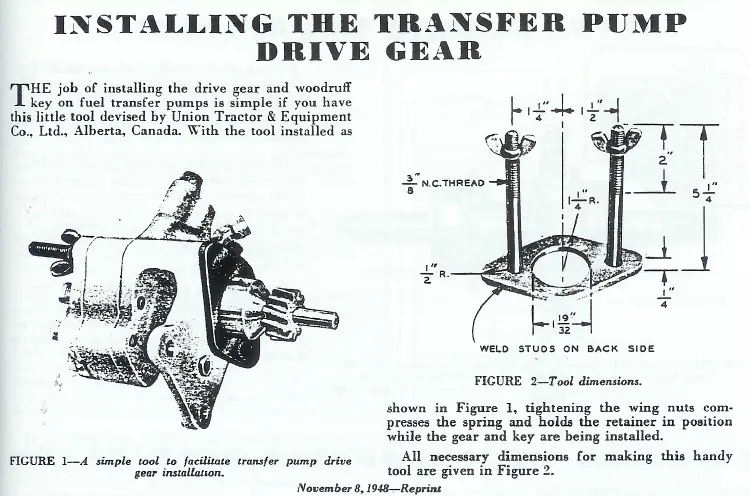

I have added the Cat drawings for compressing tooling and the guide tooling that is for D4 etc up, you can modify the dimensions to suit the D2 as described below. The one I made has the same taper and outside diameter as the D4 but is longer (2.875") overall and has a full length bore the same as the smaller diameter shown in the drawing. I used a drill of 11mm diameter as this comes out at the imperial size bore needed to achieve a bore that did not need the reamer to get the neat fit for the shaft diameter--the bore inside is around 1.825" deep on the straight sides--not allowing for the drill point.

Use the guide tool to slide the packings past the sharp edge at the gear step diameter change or you will catch the packing inner bore and jeopardise the packing inner seal surface.

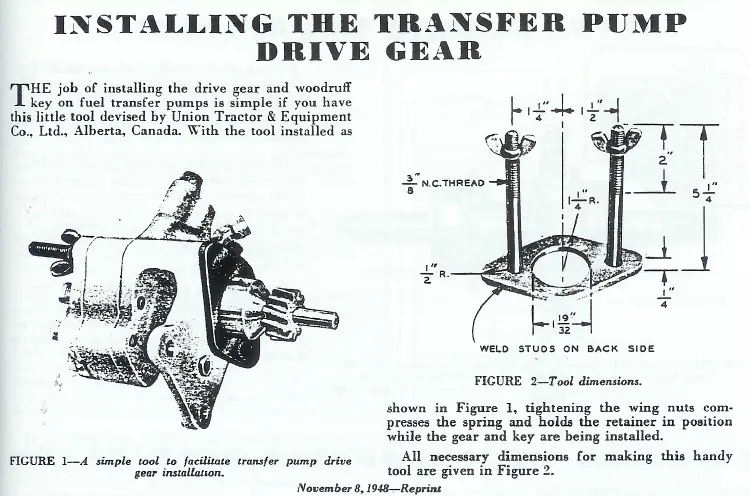

I made my cone spring compressing tool the same as shown above by using a piece of pipe with a suitable inner diameter and added the ears to suit--I used some long/all thread stock to make suitable studs/bolts for drawing down.

Hope this helps.

Cheers,

Eddie B.

Cats Forever

I'd highly recommend making the tamping guide out of tool steel and hardened as the one I made from mild steel lasted for one installation. The thin walls are very delicate.

Hey Neil, the tool to hold the spring down can easily be made. I used a bearing splitter and a piece of channel iron for mine but you could just cut a piece of steel and use some clamps to hold it down until the gear is on. I just used an appropriate size deep socket to tamp in the packing. Mine runs in the green with the pony motor and pegs the gauge once the main starts.

If I was going to do a bunch of pumps I would make the tool but for one here and there I just used what was at hand. The packing that I got from Cat was quite stiff and I had to open it up to get it around the shaft so there wasn't a problem getting it over the step in the shaft. When you tamp in the packaging you can feel when it hits bottom and seats. According to the Squatch video you just want some resistance when turning the shaft. [attachment=64155]20210501_111408.jpg[/attachment][attachment=64156]20210501_100700.jpg[/attachment]

Hi Team,

I use the installer sleeve to slip the packing over the shaft and into the main housing, remove the sleeve and for the old rope style packings you need to tamp or press fairly well to set the packing. Then I install the sleeve into the cone packing and install it into the cone and tamp I leave the sleeve in place and fit it to the shaft at which time the sleeve is forced out of the packing as the cone is installed and the clamp then used to pull the cone into place to enable the drive gear fitment.

The machined ring on one side surface of the gear faces out to indicate it is a later gear used from an update that was done, the drive ratio was changed to make the transfer pumps turn faster for better fuel pressure--the ringed gears cannot be interchanged with the old un-ringed ones and vice/versa or gear damage will ensue--the said gears should be a different tooth count and diameters would be different also.

I will see if I have any data on the change which I feel was back in the 1930's--and post if found.

The new style wrapped packings fall to pieces if tamped and should only require a fairly light pressing to set them as they are softer than the older rope style packings--there is also a stronger packing compression spring that came in at some time--ensure this is fitted to keep more crush on the packings.

An insufficiently tamped/pressed packing would show as fuel leakage at the tell tale drain tubes or engine oil dilution if both leak as was the case of the 212 Grader we worked on recently due to the fuel tank being lower that the filter tower--yes, we had fitted new gaskets, another surfaced lid, and bleed taps and bodies to no avail thinking air was leaking in there, --air would bleed into the filter tower via the non tamped packing fitted from some time in the past history of the unit and thereby causing hard starting.

Cheers,

Eddie B.