[quote="Tugger"]I recently went to start my d2 after it had been sitting for a while.Pony fired up and I started rolling the main over. After a few turns I noticed engine oil leaking from the cooler.Its the cooler built into the side of the rad,looks difficult to reproduce.The local rad repair guy looked at it and said he couldn't open it up to block the leaking tubes.Are there any reproductions made?Seems buying a used one might be leading to the same problem unless it tests out.If I was to test one one what would the test pressure be?

Thanks in advance for any advice

D2 4u1605[/quote]

Tugger, I disassembled one end of a cooler that was completely ruined. Found that the end cap is silver brazed together and was impossible (for me) to remove intact. The construction is round tubes with baffles in each tube.

If your leak is on an outside row you might be able to cut out the local fins, cut the tube, and seal the tube sheet. Unlikely that there is only one bad tube. There is a place in the North West that is making aluminum replacements. I would rather have a nice steel one, afterall, the original has lasted a long time. I haven't got around to that project yet,,,,,,,,

I have a small experiment under way re: the oil cooler. I've dipped the lower end with the rust holes in POR-15 about 20 times, building up layers (100 would probably be better). Once I get the main engine going, I'll hook it up and see if it holds. I think the max oil pressure is 30-40psi.

It probably won't but I'm interested to find out.

I have a small experiment under way re: the oil cooler. I've dipped the lower end with the rust holes in POR-15 about 20 times, building up layers (100 would probably be better). Once I get the main engine going, I'll hook it up and see if it holds. I think the max oil pressure is 30-40psi.

It probably won't but I'm interested to find out.

[quote="Neil"]I have a small experiment under way re: the oil cooler. I've dipped the lower end with the rust holes in POR-15 about 20 times, building up layers (100 would probably be better). Once I get the main engine going, I'll hook it up and see if it holds. I think the max oil pressure is 30-40psi.

It probably won't but I'm interested to find out.[/quote]

Neil--so far I am really impressed with that Locktite steel fiber epoxy---time will tell!

That's a thought Dan, might pick some up over the weekend and mold that around it too

I thought that with patience and skill a guy could dismantle the cooler and replace the tubes,but when the guys at the rad shop,who are very good said it couldn't be done I had to drop that idea.If I can find a replacement,ill probly open the worst of the two up and see what could be done.The silver soldered ends and precise dimensions seem to be the impass.Maybe with an assembly jig to hold the ends,the core could be replaced .there must be brass core available in some form.

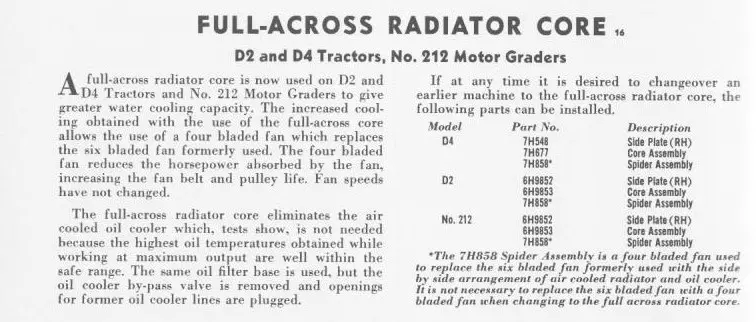

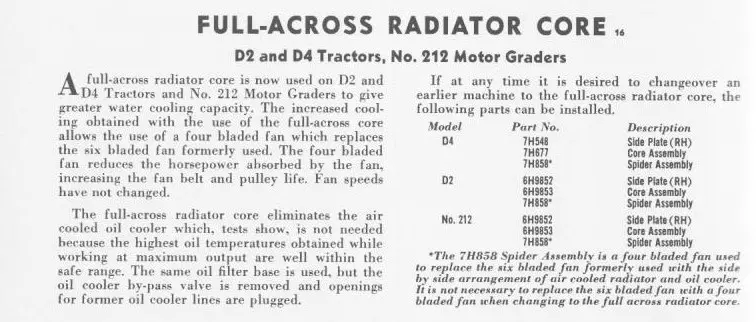

Service Magazine article on this subject.

Cheers,

Eddie B.

The oil cooler on mine has never been hooked up and haven't had any problems.

I like the idea of plugging the lines and leaving it in place so it looks original