The gauge reading 1/4 while cranking is within normal limits. I doubt it is the reason for hard starting

If your valve is missing a rubber, it will be attached to the little poppet that sits on top of the spring. On the other styles of bypass valves, the rubber will get hard and fail to seal properly and in extreme cases the cast iron seat can even get worn.

ok maybe need some more bleeding of the fuel system.

Does anyone know what this setup is? The pump looks to be the correct one but the bypass system looks nothing like anything in the parts book. They all show a cover with 2 bolts holding the plunger and spring not a plug like mine has.

my limited experience is such that I think this system requires some positive pressure to be placed on the tank via the filler to fill and bleed the system efficiently. You can spend an awful amount of time otherwise waiting for the system to fill and bleed by gravity assisted by the weakish pump system.

If your engine serial number matches the chassis serial number, then only thing I can think is someone found a more modern pump that would substitute for the old style. If serial numbers don't match the engine might be a transplant.

Seems to be a perfect fit.

That bypass valve arrangement looks like what is used on the very early D2 J models and the D4 4G series. The plunger does not appear to have a resilient seat.

Plunger part number is a 4B519

Spring part number is 4B517

Hi Tom,

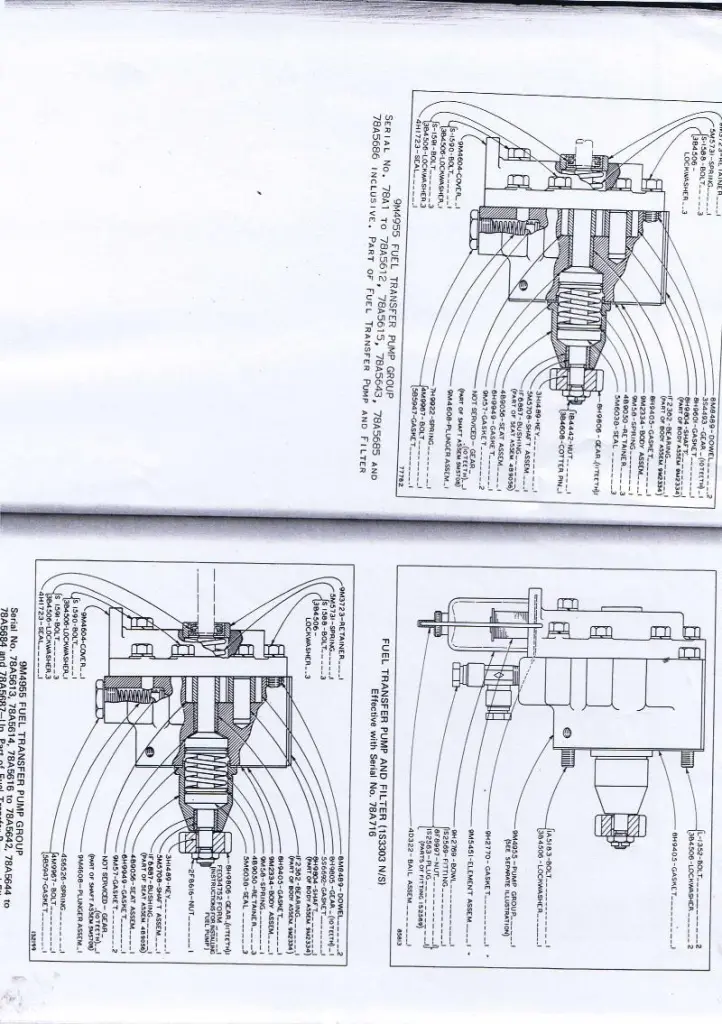

the pump parts picture is from a D4D 78A.

As was said above maybe your pump or engine is a transplant from a later Industrial engine or some other application like the 212 Motor Grader that uses that style transfer pump.

I do understand that your transfer pump is different to the old style shown in your parts book--does the D4D plunger not fit your pump? I am not sure what, other than the cited pump difference, your question is.

Have you tried the D4D relief valve yet for suitable fit.

From memory, the old black plastic button type RV plunger is superseded by the rubber seat steel plunger and should work, also those new style rubber seat plungers come in at least 2 sizes which may be your problem. The one used on D343 engines I think is smaller and is P/No 8M0874.

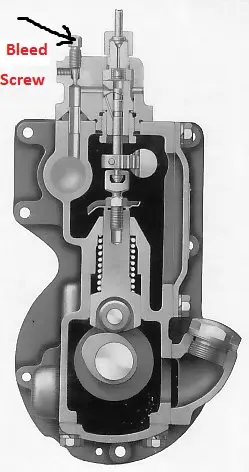

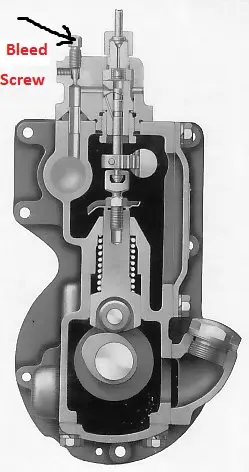

A lot of starting problems arise from not Fully bleeding air from the fuel system.

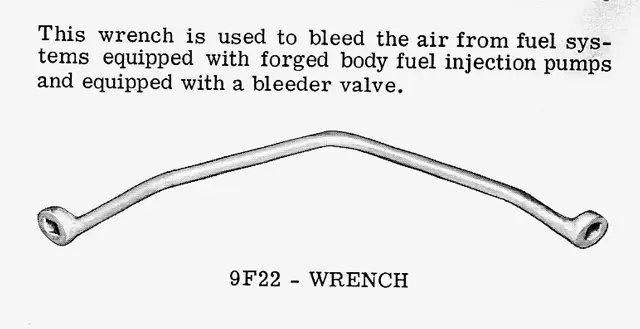

There are little bleed valves at the rear of each injection pump body that it is essential to bleed all air from several times until air free fuel issues from the drain ports at the rear of said pumps.

You need a tool like a socket that is used to hold auto shock absorber studs with, they have 2 flats the same size as the pump bleeders.

There is a special Cat tool for the job, P/No 9F0022 Wrench, I believe that Cat now supply these sockets instead--likely cheaper at an auto parts store.

Hope this helps.

Cheers,

Eddie B.

...another problem I encountered was that the gasket fitted to the top cover of the filter tower was found to be wrongly installed which caused low fuel pressure and fuel to constantly drip from the overflow pipe.

I'm still not sure how this caused such problems but when a new gasket was fitted correctly it cured both problems!

When I have some time I will examine the system to see why - but I did note a small hole in the tower that supposedly connected to another in the lid and which was blocked off by the wrongly fitted gasket.....Conversely the gasket was not sealing correctly probably causing a short circuit and allowing fuel to pass into the overflow pipe.

By then I had spent several hours pulling everything apart - including the pump and was about to embark on a full pump re-build.

I guess the point is.... never presume everything is correctly fitted...