Gaskets are mostly available from Cat, Olson's gaskets is a good source also. Try Florin tractor or General gear for parts. Cat has a surprising amount of parts available also. BMR on this forum has a lot of parts and is great to deal with. I have a d2 parts tractor and might be able to help you out

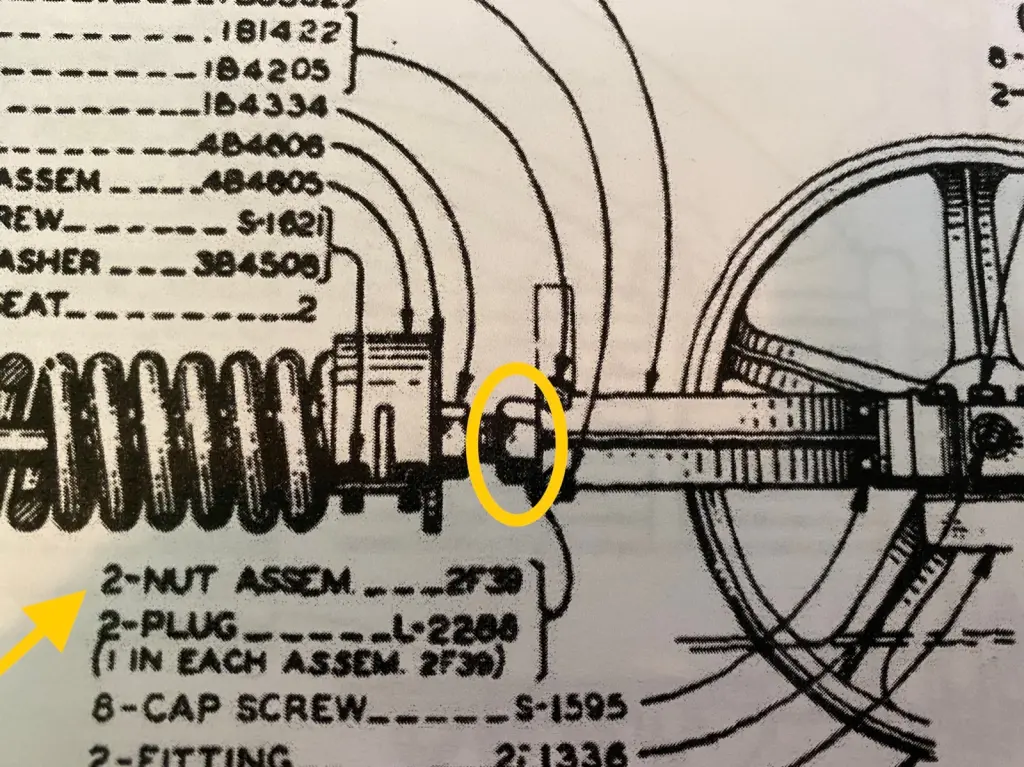

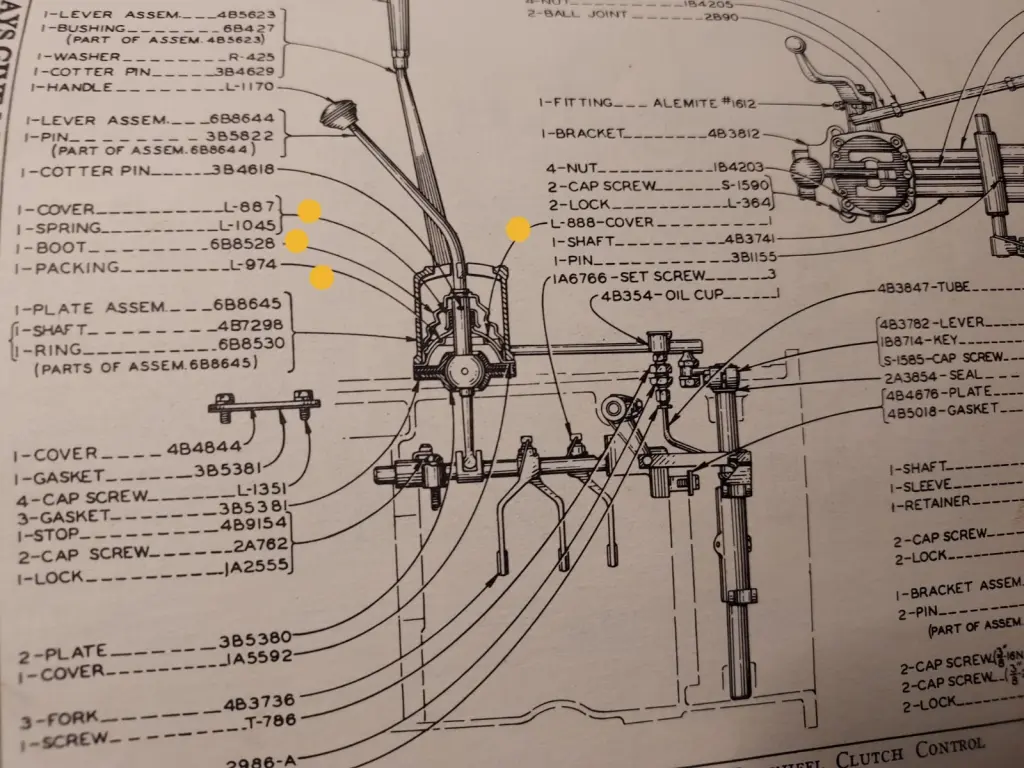

I think this should cover most of your shifter [attachment=65666]20211206_191838.jpg[/attachment]

Excellent pics! If you’ve not spotted Squatch253 or Pacific Northwest Hillbilly’s channels on YouTube I highly recommend their content if you’re more of a visual learner like me.. Squatch253 has whole videos which are searchable and linked on the members Tech Library and he’s done an outstanding job of teaching and illustrating these parts, I’m sure you’d find an illustration of the correct orientation of that bracket. And thanks for the pic of the track adjuster nut, I’ve been looking at mine and wondering how it looks when removed! Always learning..

Tony

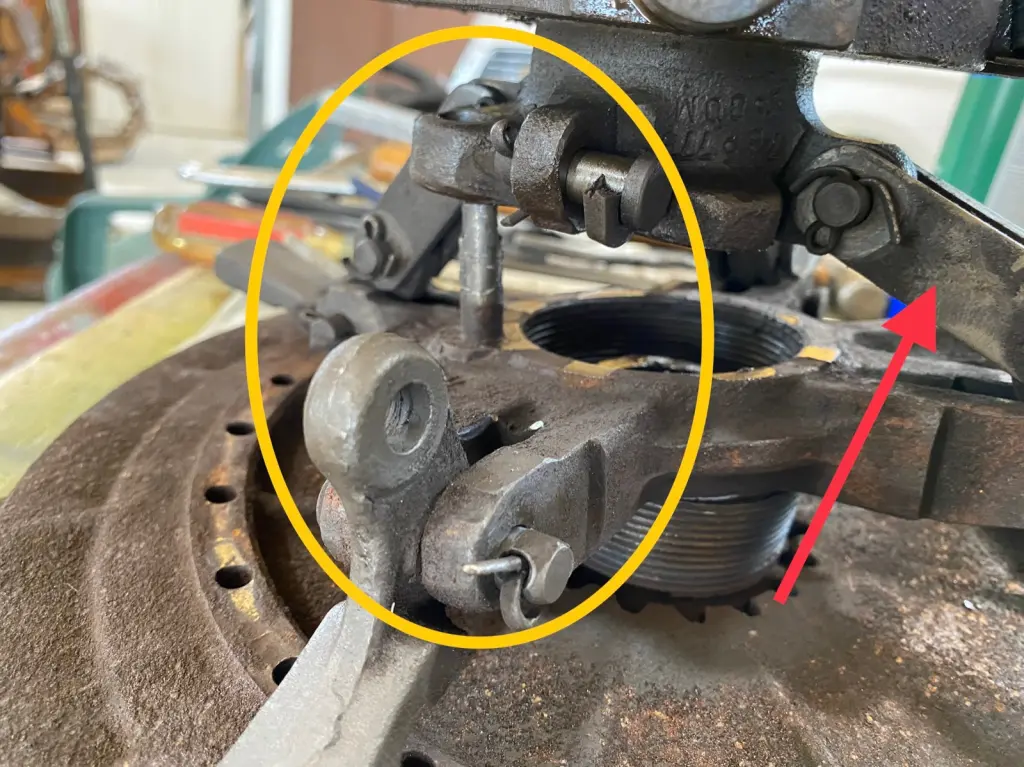

The D 4 6u I have had the same broken links, found wear in clevis's, pins, holes, clutch collar was allowing to much movement forwards of the clutch yoke and would hit the adjusting assembly where links attach, replaced clutch plate, filled and drilled clevis's and holes, new pins, new collar (fixed the slack in system) to reduce travel forwards to stop the clashing yoke and link corners.

Thank you for the picture if the inside of clutch housing.

Can anyone advise the reason for the D2 clutch dragging or not releasing? My machine drags to release the clutch occasionally (cold or at temp), a touch on the foot brake or clutch brake sorts it to release fully, seems a regular theme.

Cheers

Jamie

[quote="Busso20 post=233689 userid=16170"]

Can anyone advise the reason for the D2 clutch dragging or not releasing? My machine drags to release the clutch occasionally (cold or at temp), a touch on the foot brake or clutch brake sorts it to release fully, seems a regular theme.

Cheers

Jamie

Hi Jamie,

I believe that the dragging you experience could be due to over greasing of the clutch pilot/thrust bearing over a long period. My 5J D2 does the same.[/quote]

Hi John,

Thank you for the tip I shall check out how clean it is next time I need to adjust the clutch.

Cheers

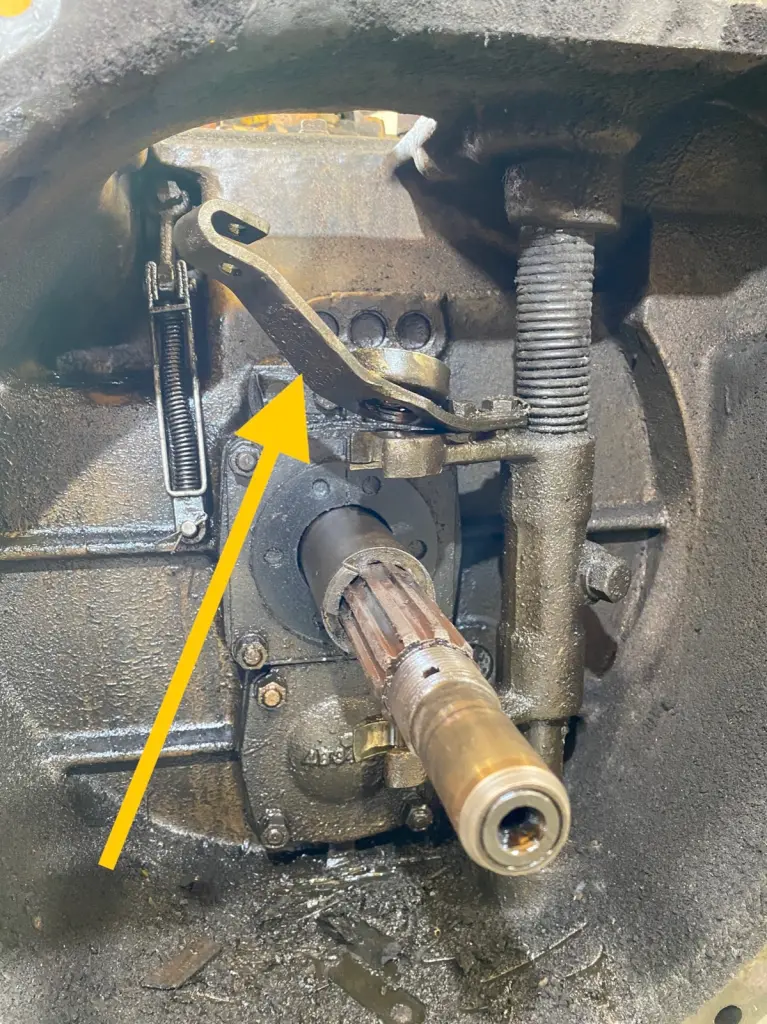

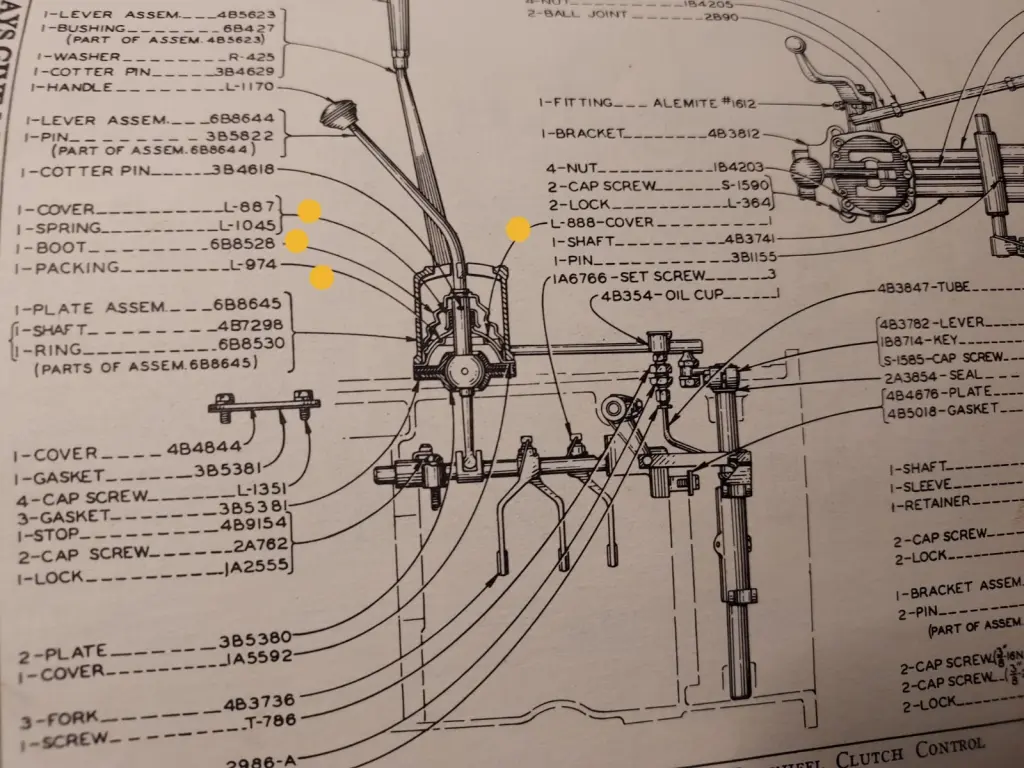

Hi Busso, good advice from everyone here. For that bent bracket you asked about originally, I don't have a photo to hand but the bend that is on the right side of the oil cup in the picture should not be there. It should be flat. The two bends on the left side are correct and serve the purpose of getting the pin hole raised up to the right height for the linkage. Your dragging clutch could also be due to wear resulting in lost motion i.e. you're moving the clutch control lever the full amount but the clutch disengagement mechanism is not moving as far as it should. When you push the control all the way forward, it should activate a clutch brake. Your 1/4" of slop in the vertical clutch relay shaft is probably responsible for most of that lost motion but you can also check the "thrust" collar which is a brass two-piece part. That can wear internally and also contribute to a lot of lost motion. I had to replace mine and I got it from General Gear, same place that I got my steering clutch components from. You can get a new vertical clutch relay shaft bushing from Cat or if the hole that it presses into is worn and sloppy, you can just get a local machinist to make one with an oversize OD out of bronze - shouldn't cost more than about 30 clams.

My track tensing bolt/nut wouldn't tighten my track up---I added a couple of nuts behind the adjusting nut to get to good threads on the bolt