Hi Vinny,

to my knowledge there are no specs for this test, Cat do not believe in this test.

They used to use a cylinder leak down test which has lost favour also.

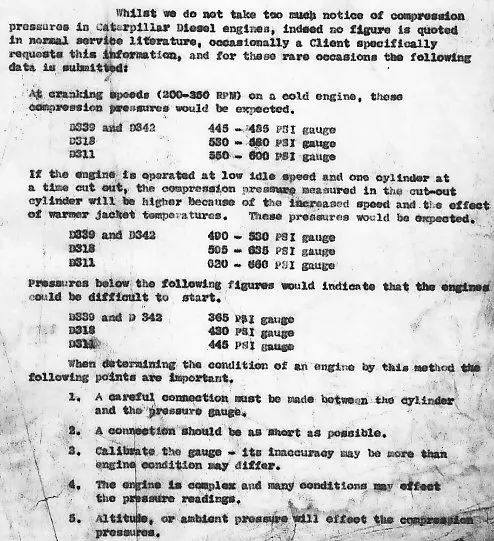

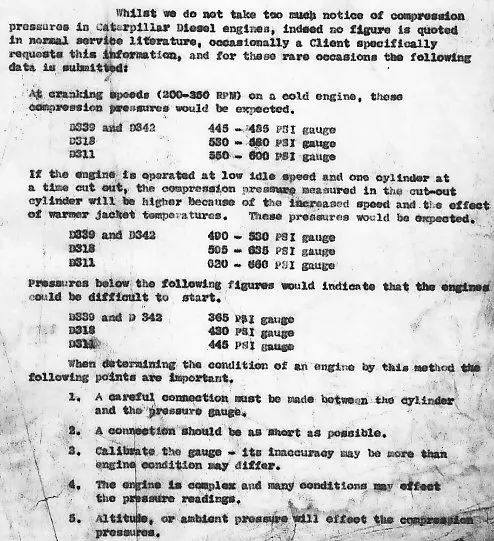

The only data I have on a comp test is for a D311, and others, engine and the values may or may not be similar for your D2. Cat engines are fairly low in compression ratio so compression pressures are not very high.

A good guide will be the evenness of your test results. You will have to make a suitable adaptor to put a Diesel Engine compression test gauge into the precombustion chamber where the injector has been removed from.

Most hard starting problems stem from poorly atomising injectors, low Main engine turning Rpm from the pony engine governor being sticky and therefore turning the Main at less than rated/optimum starting speed, and not allowing enough run time with the pony to warm/condition the main to a suitable starting temperature, especially the combustion chambers.

A lot of people think the pony is to be used like an electric starter, but, in fact it is used to get heat into the cooling system and the combustion chambers for a good start. The pony run time is dependent on engine condition and Ambient Temperature and can be 5-10 minutes or more or even less if the engine is warm from previous running. After oil pressure is registering the compression lever should be moved to full compression to build up the heat in the combustion chambers.

From previous trouble shooting at The Dealer I came up with the following Main engine Rpm's when being turned by the pony running at its rated governed speed of 3,000 Rpm for a D2 both with the D311 4'' bore engine and the D3400 3 3/4" bore engine is 335 Rpm. Your D2 has the D3400.

As usual save this chart to your 'puter as it will be removed in due course as other posts take preceedence in the near future.

Hope this helps.

Cheers,

Eddie B.