How many joints do you have in your arms? Ha! Ha!

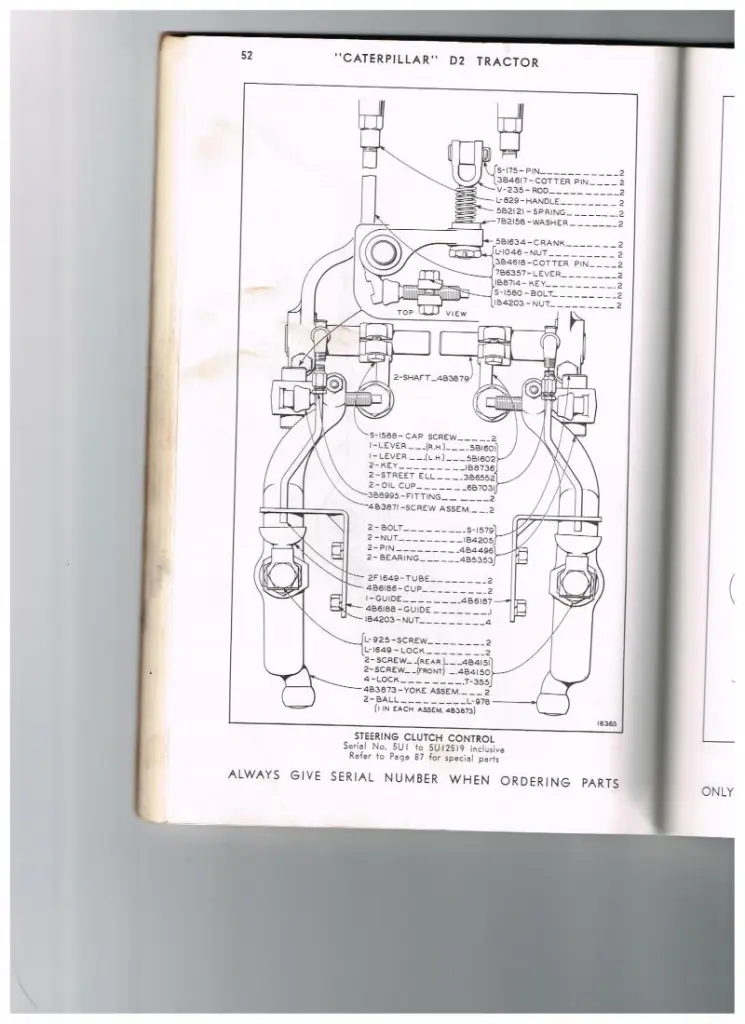

I think the bolt you are looking at just holds the funnel for the oil drip tube, and is not one of the pivot bolts. However I expect the clutch release bearing has failed and is the problem. That might have been why you had a variable pull there for a while.

How many joints do you have in your arms? Ha! Ha!

I think the bolt you are looking at just holds the funnel for the oil drip tube, and is not one of the pivot bolts. However I expect the clutch release bearing has failed and is the problem. That might have been why you had a variable pull there for a while.

L-925 does just attach the aluminum funnel. The two larger bolts that hold the yoke to the bearing carrier, I have never seen them get loose, usually they need heroic measures to remove. Best with a offset box wrench and a pry bar wedged to keep the wrench from slipping off the thin bolt head as I beat the wrench handle. I would look closely at the throw out bearing, and for lost motion in the bell crank assembly.

Sorry to say the final drive removal will be necessary. The way I did it was to remove tracks with master pin at the back of the sprocket, roll the top of the track to the front of the tractor and lay out on the floor. Next securely block up the front high enough so you can remove the center spring. Then remove the 4 large nuts that hold the pivot shaft in place, block up the back buy the draw bar. at this point you should be able to roll both track frames and pivot shaft forward on the tracks a foot or so to get them out of the way. At this point the finals can be remove as a assembly.

OK. Just to be clear, you removed both tracks and moved both track frames forward?

Can you do that without removing the tank and fenders or did those need to come off also?

.webp)

The fenders, seat box have to go, they can be removed as 1 unit,

I went through both steering clutches on mine so it worked out well the way I described it, if you were to do only one side I might take a different approach.

Now that I look at the pictures I didn't remove the spring, I just raised the tractor so the spring would clear the pockets in the track frame

I found a few pics of that project

Its really not that bad! I've done a couple and the last one was a full 10 hour day but I had all the parts necessary too. I took the fender and seat off, then did close to the way Steve did it. The admitted benefit is after the first one you pretty much know what tools you need to do it!