The gear mesh back lash doesn't really matter so long as they mate and seal. Side/end clearance can be anywhere from close to zero to a couple of thou. total. When your at about 0.004 to 0.005 between the gear teeth tips and the wall of the housing and/or side clearance it's considered worn out.

Thanks O.M.

I figured I could count on you (almost sent you a pm). I'll check the gear tooth clearance Monday at work, ...during lunch break of course, never on company time (:flypig😊 and maybe dust a thou or two off the housing.

Still have all those transfer pump parts sitting on my bench at work (I do wipe the dust off them occasionally). My big concern now is about the pump Shaft. The shaft looks and mic's good at the bearing surfaces but is worn about .0015" to .0022" where the lead Seals ride. Should I replace the shaft or just stick it back together and use it?

I have not checked about price or availability on a new shaft yet. I could make a nice new shaft in a couple hours, but that requires ambition which I don't have an overabundance of at the moment.😆

[quote="zootownjeepguy"]Still have all those transfer pump parts sitting on my bench at work (I do wipe the dust off them occasionally). My big concern now is about the pump Shaft. The shaft looks and mic's good at the bearing surfaces but is worn about .0015" to .0022" where the lead Seals ride. Should I replace the shaft or just stick it back together and use it?

I have not checked about price or availability on a new shaft yet. I could make a nice new shaft in a couple hours, but that requires ambition which I don't have an overabundance of at the moment.😆[/quote]

I located a new shaft for mine on the grader. $110 nos.

i had mine ground and chromed to specs.

Hi Rich,

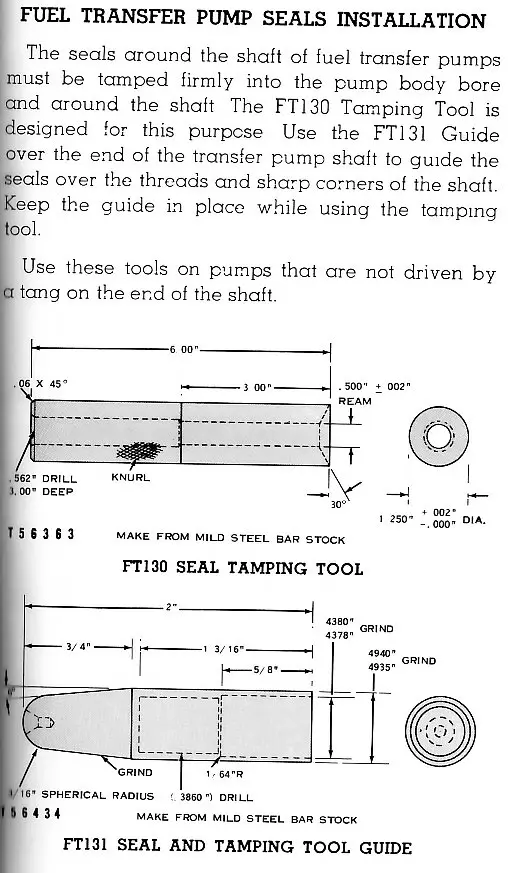

the main things with these pumps is that the end clearance is down to minimum, about 0.0005"-0.001" and that you make up the tooling to tamp the seals good and tight on the shaft or else they leak out the drain tubes or worse still back into the engine oil if the tubes are blocked.

The good book says 0.001"-0.0022" clearance with a max of 0.0035".

Shaft clearance in bearings is spec= 0.0012"-0.0019", max 0.003"

No spec is given for gear teeth end tips to housing but 0.004"-5" would be max. I think, as OM said above.

Polish the end cover and body surface and use permatex No 3 to seal them.

I guess you have checked the relief-by-pass valve seat and face, also that the spring is is good condition, a bit of a stretch usually ups the pressure a bit.

Spring spec is free length= 1.64" and 2.16-2.54 lbs force at 1.031" compressed length.

Fuel pressure should be around 25-30 psi at full load and 3 psi at cranking speed.

Scans below are for the tooling to tamp the seal packings and onr to aid in sliding the square shoulder of the shaft thru the packing.

Grab these scans while they are up.

Hope this helps.

Cheers,

Eddie B.

How long would it take a Mechanic at William Adams to fit the 2 new seals into a dismantled D4 transfer pump?

thanks

Mike