Reply to STEPHEN:

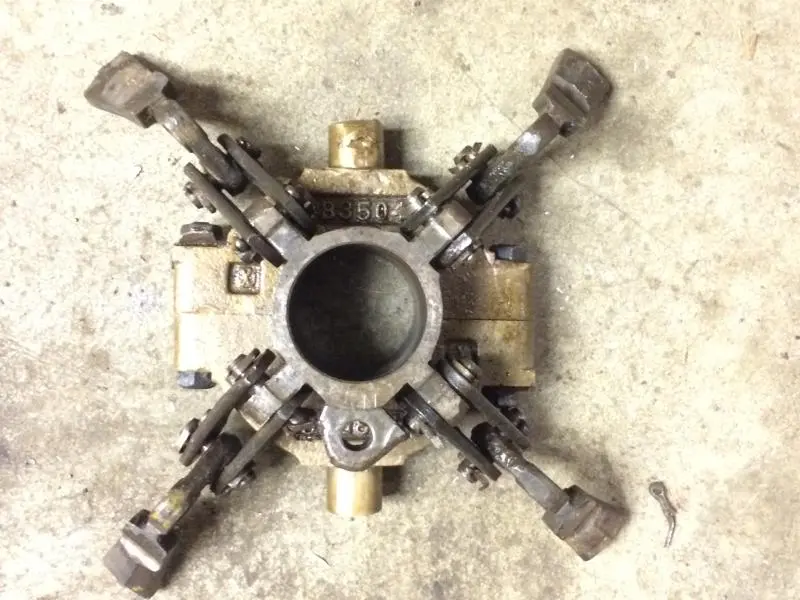

[quote="Oldcarman"]Working on a 5J70 and got the clutch parts disassembled. Putting in all new pins and collars after reaming to M10. That will take the slop out of the links quite well.

How about the bronze clutch collar. Is this typical wear? I don't want to spend $250 on this if this one will run just fine. The plan is to get this machine to operate well, but not prep for a hard working life...

The plates are pretty rusty, but going to have them resurfaced to flat, but not gonna worry about pits. The driving disc has very little wear but has some hairline cracks on the surface. The teeth look good. I'll post some pics of that too.[/quote]

I like your idea of reaming to M10 to save those parts. Building bronze on bronze is tough, so one thing I have done where I only needed a little extra fit (like on your collar trunnions) is build with silver braze, usually with 15% like staysilv 15. It it's not too soft and can be machined, filed, etc.

Progress- Going to order a new bronze release collar. Got all the pins made from M10 gr 10.9 bolts. Had to turn a new pin for the adjusting lock as the original was bad. Also had to make new pins for the springs. Got stainless springs from McCarr that worked well.

Local clutch house cleaned up the clutch surfaces and also flattened the driving disc a bit. There was virtually no wear on the original, but warped just a bit, so flattened it a bit on their flywheel grinder. Same guy that worked on a clutch for my 1929 Pierce-Arrow about 20 years ago. He said he had been working there 40 years. That's a lot of asbestos dust....

Clutch is tight, no slop in the links or pins so that part is good. Now I've got to figure out how to bore the cast iron clutch housing to accept a bushing for the 1" shaft. I just bought a NOS Sioux valve seat cutter (for installing seats). If I can figure out how to pilot the wallowed out shaft with a Sioux stem pilot, I could bore the housing. I'm gonna study it a bit more tomorrow and then make a plan. The hole is so wallowed out it is going to take some kind of pilot to bore the top hole.