Have a D2 3J3006SP it will not make any fuel pressure while cranking, have checked spring and bypass valve.

Will not fire on diesel.

Have got diesel at fuel filter bleeder.

Have got Diesel at each injector pump at bleed screw.

If i pressurize fuel tank with air i can get fuel pressure to go into the green scale but still will not fire.

Crack injector lines and they squirt a little bit of fuel.

Rack is moving gears are timed to rack on pumps.

Pumps are rising and falling with injection pump cam.

decompression cams are moving intake valve not stuck

Any other suggestions

Do i need to replace the 4 injection Pumps?

Does it fire on ether? If not I would be doing a compression check. Start from the fuel tank moving forward, clean/check that you have good fuel flow, sometimes the fuel line is plugged. I have seen tons of cats run and gauge not read accurately.

as Clayton asked does it fire on ether--starting fluid.

If so then it seems rack may be in stuck in the shut off position--can you gently move the rack bar back and forth--sometimes the bar can stick in the off position as it is only the governor spring tension that moves the rack when the governor control quadrant lever is moved to the fuel on from the stop position.

The only positive pressure on the rack is when moving from run to stop.

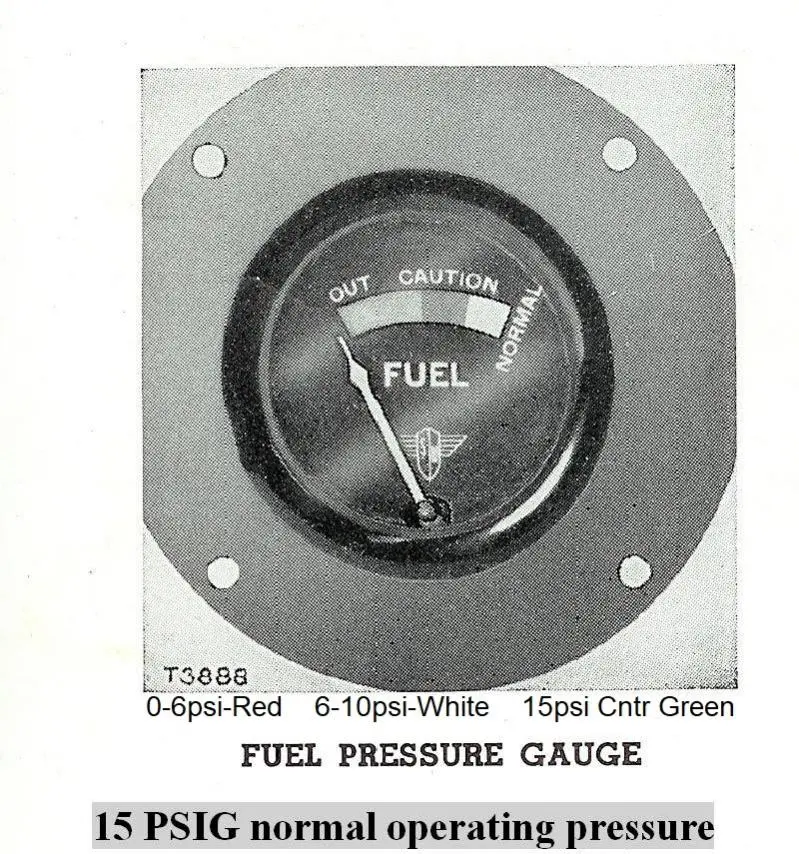

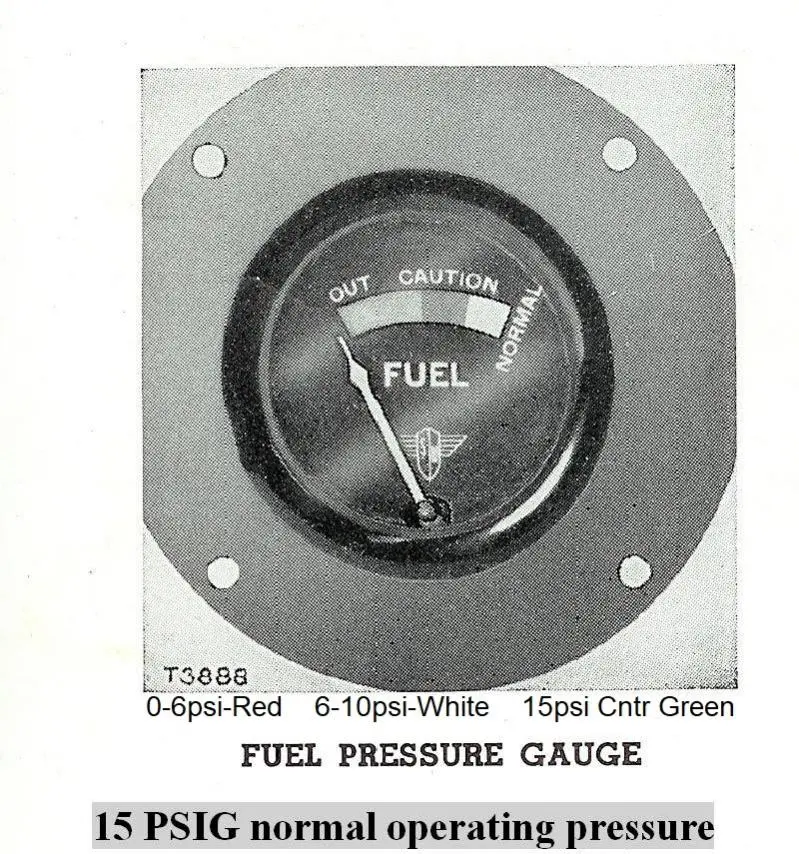

The fuel pressure gauges read as per scan below.

Cheers,

Eddie

B.

So i have no fuel being squirted out of the injectors on the D2.

If i take said injector and put it on the d4 pump it squirts straight away.

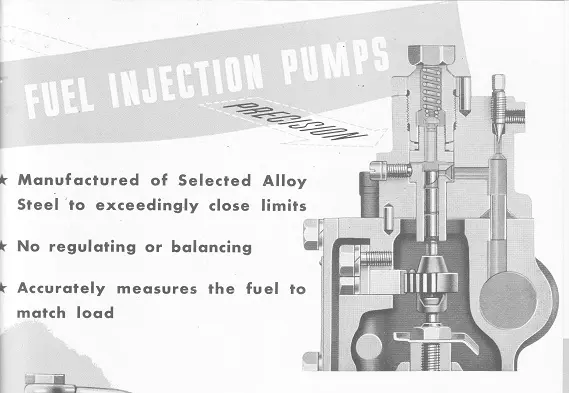

I think the Pumps themselves are not generating pressure bypassing internally.

This is the order I'd troubleshoot in:

bleed the filter tower - if nothing, then your transfer pump is no good

bleed the injection pumps - if nothing, your pumps could be stuck up, or stuck closed, or damaged internally

bleed the injection valves - if nothing, your injection lines could be plugged. Take one out or use a spare and connect it to each line to confirm that you get a decent spray. Keep your body parts out of the line of fire of the spray as getting injected by diesel can be life-threatening. You can use a piece of cardboard to check the pattern.

You've done all of that, so like train and Eddie said, check your compression. If there's no noticeable increase in lugging when you flip the decompression lever, then I'd check that the lever(s) is/are connected up the correct way. It can be connected 180 degrees out meaning you don't get any compression no matter which way you flip the lever. Take the rocker cover off and confirm that you have satisfactory valve lash when set to compression. If not, disconnect the link where it connects to the four levers on the side of the block and flip them up or down until you get good valve lash. Consult the serviceman's reference for a picture of the correct lever orientation. Since you have the valve cover off, check all the valve lashes too. Was there any crud in the intake or exhaust manifolds? Could be preventing the valves from seating properly.

As Neil suggests have you bled the injection pumps at their bleed screws situated at the rear of each pump unit--there is a special wrench for this purpose but a modern shock absorber socket for the type with two flats to enable undoing their retaining nut work well for this task.

Neil and edb I can confirm those ole girls don't start without bleeding the pumps after changing and cleaning filter tower.