Yes, has been a while.....

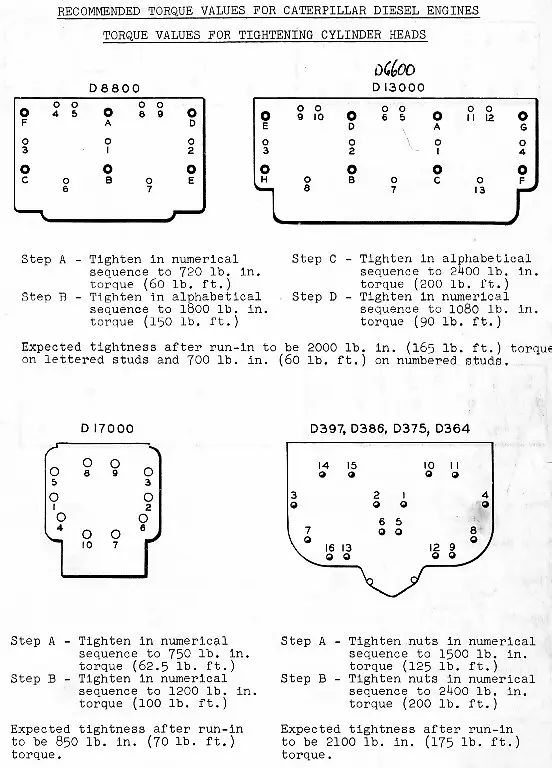

Those are the torques I read also, with an expected tightness of 70 ft-lbs after run in.

Sorry, can't help with the welding process or parts locating.

Could you be thinking of Florin Tractor???

I don't have a parts book but I would suspect the water deflectors are common to other engines.

I don't think "spray welding" is the process you want. Spray welding with a torch is good for building up thin layers on shafts etc, but I have not heard of using it for thicker layers.

I have had heads welded before. They did 2 small Yanmar diesel heads and one was perfect, no leaks now after a couple years, the other immediately leaked coolant out of the injector bore, but did not leak compression into the coolant, so we were able to run stop leak in it and get it stopped.

Look around, there are shops that still weld heads. I would think a single cylinder head would be a lot easier than a long casting.