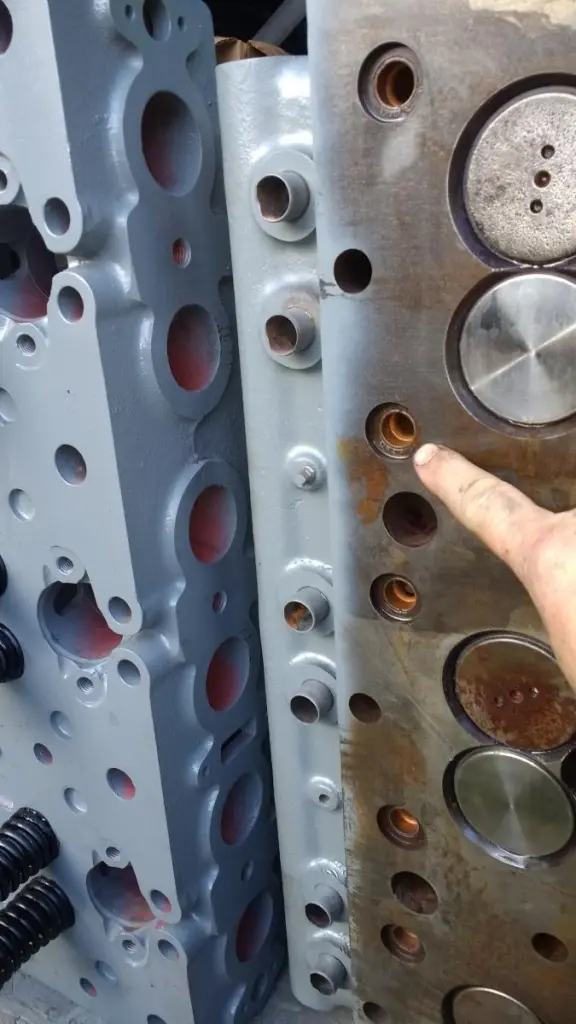

Sure would be simple to grind off a little of the brass ferrule! Just need to glue them into the head so you can get it installed without crushing one.

Drilling or grinding the deck has little room for error. I had a head on a 9U that I kept smashing a ferrule as I set it down. Finally found that one of the short dowel pins in the deck was slightly bent. Not much, but enough to make one of the ferrules catch as the head came down slightly off position.

[quote="ccjersey"]Sure would be simple to grind off a little of the brass ferrule! Just need to glue them into the head so you can get it installed without crushing one.

Drilling or grinding the deck has little room for error. I had a head on a 9U that I kept smashing a ferrule as I set it down. Finally found that one of the short dowel pins in the deck was slightly bent. Not much, but enough to make one of the ferrules catch as the head came down slightly off position.[/quote]

Yes, that's what I did a few years back to it, just didn't know if it was safe to do

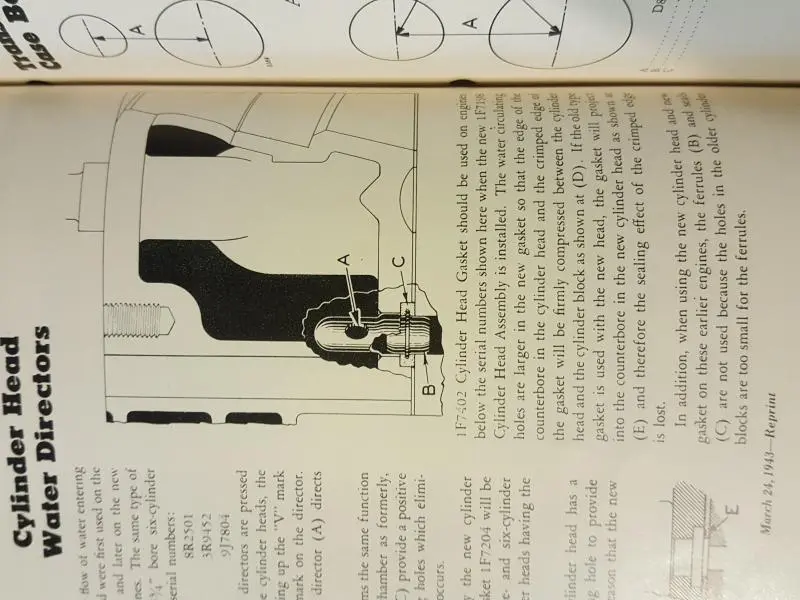

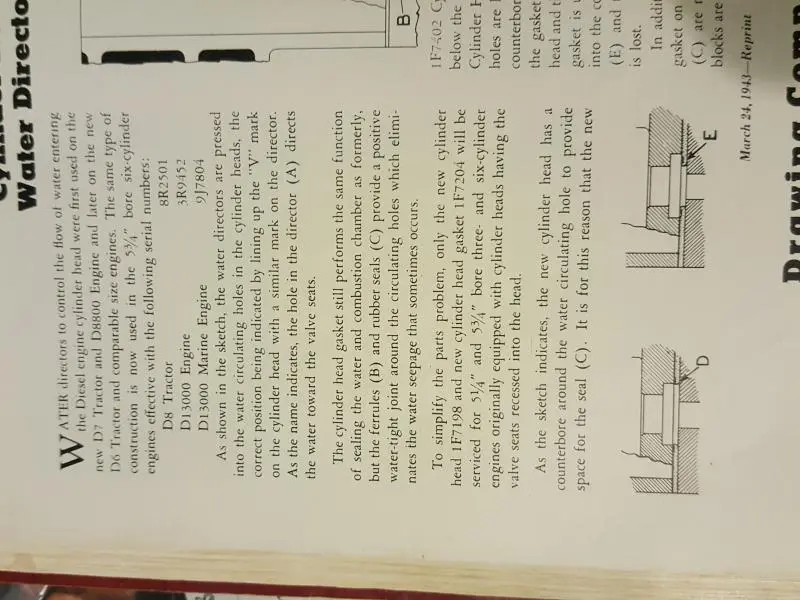

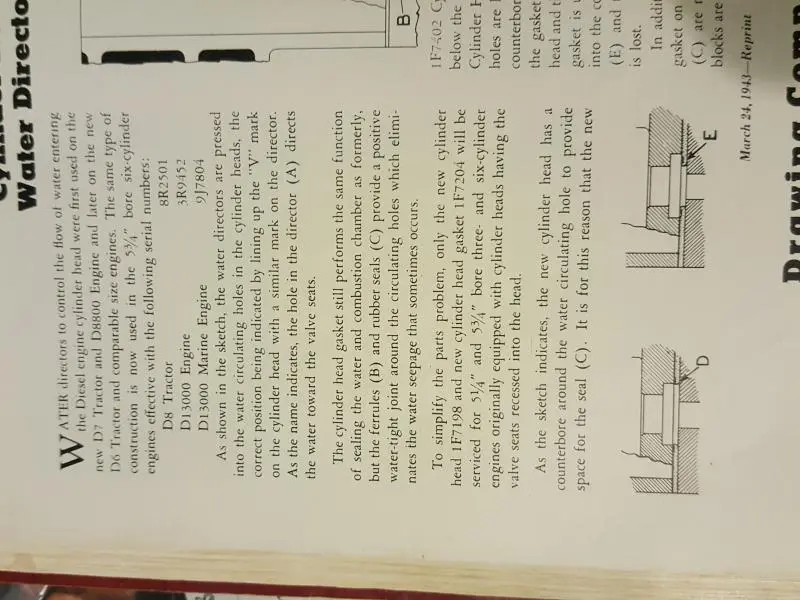

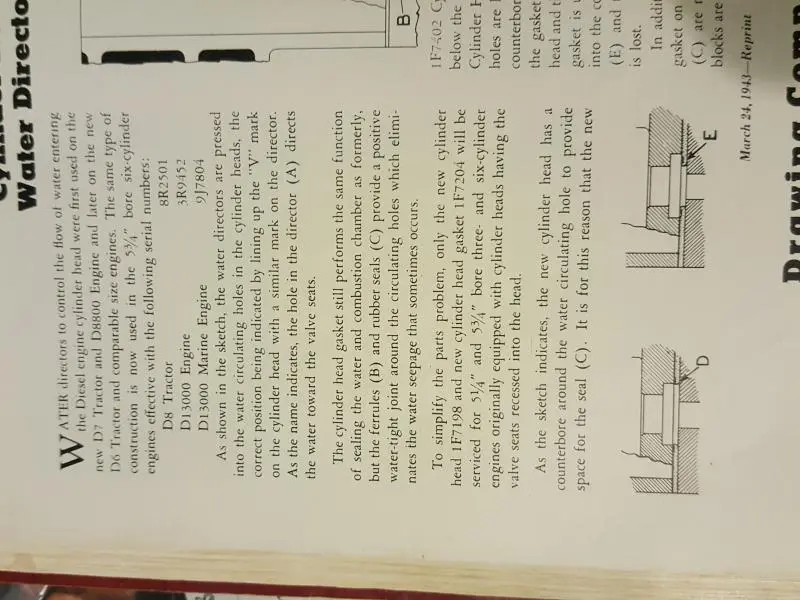

This may help.

This may help.

Sure would be simple to grind off a little of the brass ferrule! Just need to glue them into the head so you can get it installed without crushing one.

Drilling or grinding the deck has little room for error. I had a head on a 9U that I kept smashing a ferrule as I set it down. Finally found that one of the short dowel pins in the deck was slightly bent. Not much, but enough to make one of the ferrules catch as the head came down slightly off position.

This is the front cover of the book courtesy of Mike Myer.

Sorry but there appears to be no more information on this subject in this book.

[quote="Andrew"]This is the front cover of the book courtesy of Mike Myer.

Sorry but there appears to be no more information on this subject in this book.[/quote]

Looking at the 2nd pic you sent I can see part of the next page talking about it, but anyway I'm going to locate that book, thanks again for your time and help

I have that book and Andrew has provide all there is on the topic.