How much white smoke?

If you're getting clouds of dense white smoke and no start, then you need to add the ether on top of that or get it hotter/spin it faster with the pony motor.

Is the decompression lever "in" (pointing toward the radiator) or "out" (pointing out toward you when you're operating the pony motor. "out" should greatly unload the pony motor and "in" should make it really open up and bark.

If you're not getting a lot of smoke, then the rack inside the fuel injection pump housing may not be moving from the "shutoff" position. May need to snatch real hard on the throttle lever to get it to come over the detent from shutoff to run. Take the cover off the side of the injection pump housing and watch the rack move back and forth. There is no hard connection between the throttle lever/linkage and the rack, it is spring loaded in there, so you can't be sure the rack is moving just because the external crank is moving.

While you have the cover off, turn it over with the pony motor and watch the plungers go up and down on the pumps. Usually they stick up and will not come back down by the spring pressure. Also won't turn when they stick up in the pump, so that locks the rack where it is, can cause a runaway or no start, just depends on where it was when it stuck.

If you can see that it isn't really atomizing the fuel, get a set of injectors and go have fun running your "new" CAT!

If you absolutely want to confirm that they're a problem, then have them tested on a bench pump. They should "crack" at around 500 psi and have a fine evenly distributed spray and shut off cleanly. The engine should run with breaking pressure down to around 400 psi as long as they do spray and don't leak. A new set would make a difference in the performance of the engine compared to some that are as low as 400 psi. Occasionally cleaning the orifice at the tip of the injector to remove carbon and pumping them several times on a tester can improve the performance of some of them.

Rack position is forward against the stop for full fuel, it should go there by governor spring pressure when the throttle is pulled wide open with the engine stopped.

OK, good information there. I think the shutoff latch/detent mechanism is stuck or you haven't twisted the throttle far enough counter-clockwise (looking at the lever on the side of the governor). If the rack returns to the back/right when you let go of it, then it's returning to shutoff.

Might be a good idea to have a look inside to see if anything is loose or missing in there. You can see the shutoff latch mechanism best by removing the cover that has the throttle linkage connected to the lever on the outside. You DO need to take lever off the shaft! There is an additional small screw inside the round ratcheting mechanism that must be removed to get the whole thing off. The shaft inside the ratcheting mechanism has a slot that engages the part that stays in the governor housing. Once the cover's removed, the latch is at the top left corner of the opening.

The whole back of the governor housing can be removed easily, so you can get a good look inside for loose or missing components. Sounds like the rack is connected to something inside there or it would not be moving on it's own when you release it. I believe SJ had a runaway once because someone forgot to put in the pin that connects the governor to the rack. With the ratcheting mechinism installed, you can look in at the back and see what is happening when you move the throttle lever. You would not want to turn the engine with the rear cover off since the spindle runs in a bushing in the large rear cover.

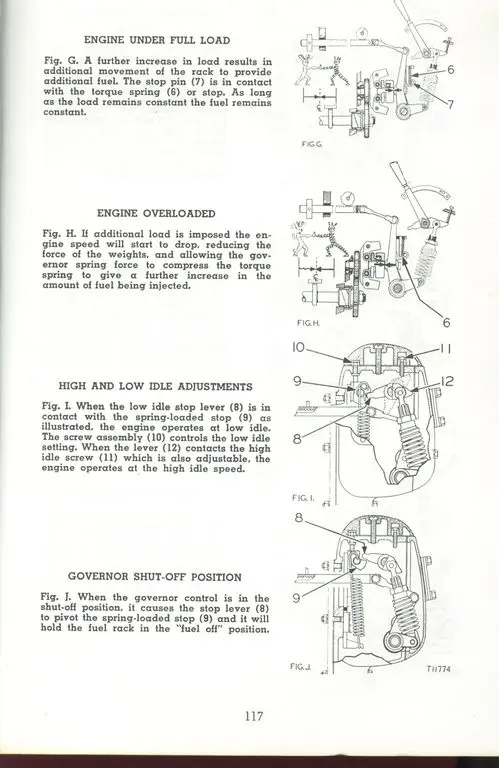

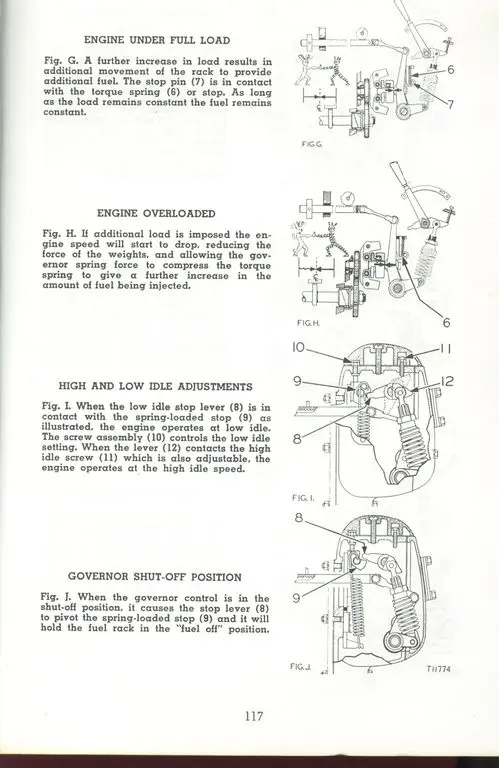

The running and stopped latch positions are shown in the lower two drawings of the page below.

Thanks for the info. looks like i will remove the govenor later in the week.I will remove nozzels and test,almost wish i had a pony motor I have almost burnt the battery cables off trying to start it.😖mokin:

Well I have tested the injectors they are trash some pop at 200 others at 450 most have little or no spray pattern . I have also disassembled the govenor found throttle linkage very worn. One question will 318 d6 nozzels work in a 315 d4? Are they the same injectors ?

The d6serie 8u and d315 motor use the same nozzles