Yea that old style is discontinued, Just have to whack the new one in. Clean the pin bosses good and oil them first.

Thank you, that’s what I’ll do. 👍🏼

Put the master pin in the freezer, clean the link bosses well lubricate and warm them. Drive the neww pin in with a hammer, please wear a face protective mask in case there is any spalding of the pin and something flies into your eyes etc.

Wombat

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

and use a drift to drive the pin this get the hammer away from the pin so less likely to swell the pin. also a drift is generally made from mild steel a little smaller than the driven pin.

freeze the pin for a couple of hrs and carry it in a ice bucket to keep it cold. if you have access to liquid nitrogen that works very well and is what the pros tend to use. but a ice bucket works too.

I just cleaned and lubed the old link bushings and the new pin tapped right in---I guess some are tight and some loser

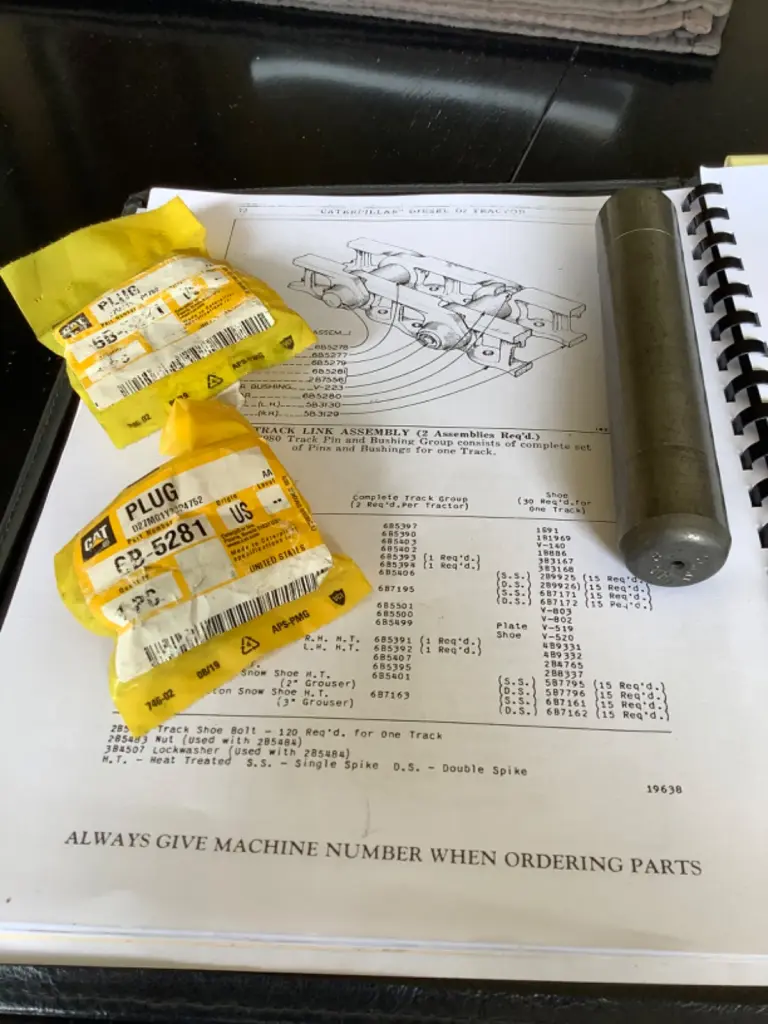

Okay, so the new pin slipped right in so there is some wear on the chain. I then annealed several pin, drilled and slotted them and sent them off to be heat treated at Garner Heat Treat in Oakland, Ca. They were hardened to Rc 50; about the hardness of an axe. I sent a new pin along with the two so they could determine the hardness. I’ll install one and put it to the test!

Hi Flathead, are you making new slotted and tapered plug pins, just like the originals? If so, I'll order 4 please! : ) Seriously....

The master pin was easy to make. I annealed the pins in my wood stove fire overnight. (I know this method is not the best) Then drilled a 3/4” hole about 1 3/4” deep in each end, the cut the slot with my die grinder. Caterpillar still sells the wedges and corks.I looked up heat treating on the internet, called them, shipped them out and there we go!