Reply to kw:

I took the information to the neighbor. He has been using the tractor, and did say one of the brakes needs adjustment all of a sudden. Maybe the lining has come off the band as you have suggested.

He wanted to mention that the top cover is hinged, making it hard to work in this area, and also that he thinks the brake adjustment if under the mechanism, and is hard to get to. Does this sound like the adjustment he should be working with, to adjust the brake? It does seem that an adjustment is not going to do the job, but probably new lining.

Thanks,

Ken

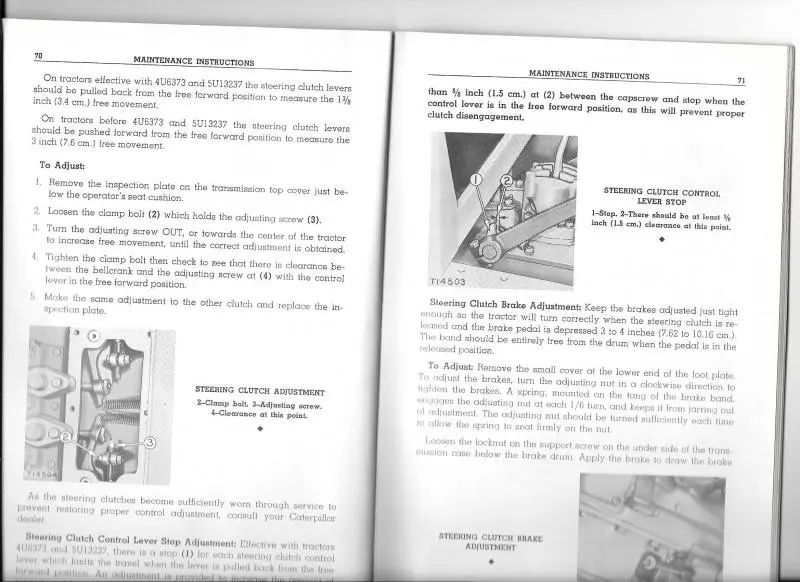

Ken, the brakes are adjusted from the top by removing the square covers just above the footwell plates. You'll find that each brake band has a nut that is turned on an eye bolt that tightens the bands to the drums. The brake adjustment underneath the tractor that he's referring to is the support bolt and jam-nut that holds the brake band up under the drum so that it's more centered around it. Once you've achieved the desired band adjustment from the top you then go underneath and loosen that jam-nut and turn the support bolt in till it bottoms out against the band and drum, then back it off 1 1/2 turns and tighten the jam-nut back down to lock it in place.

When I first read this post I also suspected a situation like Deas explained where steering clutch material loosens up and climbs onto itself increasing the clutch stack height and creating the resulting loss of clutch lever actuation, but still can't explain why the machine wouldn't roll. Now if it wasn't loose clutch material that bound up the mechanism, with the way the D2's clutch linkages are designed something else would've had to been floating around inside the steering clutch housing and wedged itself against the steering clutch yoke, forcing the yoke in towards the centerline of the machine creating the loss of control of the clutch lever, while at the same time binding the clutch/drum components severely enough to stop the machine. But this scenario isn't one that I would expect would just straighten itself back out again and not cause further problems. More info would be needed for a better guess.