Hi vansgarage,

check that the bellcrank has a long and a short arm. The long arm connects to the Governor lever at the Injection pump.

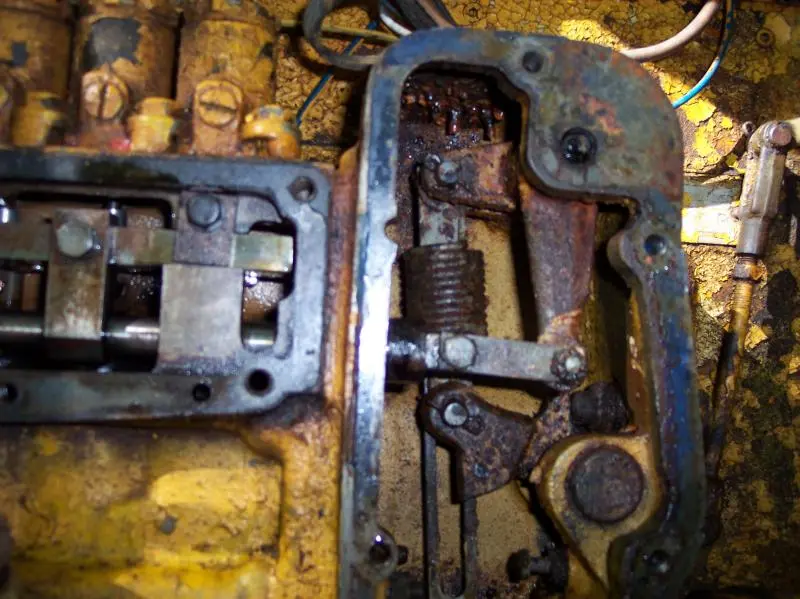

If the bellcrank is correct then, from your pix, I feel you need to adjust the yoke to shorten the vertical rod just in front of the Serial No plate to get the bellcrank to touch the High Idle stop (small screw at bottom of gov housing) as shown in pic #9. This to occur slightly before the hand lever at the dash is in the fully pulled back position.

The large screw above the the bellcrank is the Low Idle stop and it has a spring loaded plunger in it which may be seized. It needs to work so as the rack can be pulled to the Shut Off position ( by depressing the plunger) by the Stop Run lever.

Hope this helps.

Cheers,

Eddie B.

As Eddie suggested, the first step is to get the throttle linkage adjusted so that you can get the travel to take the lever in the governor housing to both it's high idle and low idle/shutoff stops. Then these rpm setpoints can be adjusted to their specified values. Once you get that done, then you're to the point where the parts of the governor have to work properly to get good governor response.

Just looking at the rust in the rear compartment, I would suspect the spring has gotten weaker and may not give you full fuel response under load, but you have to start out stretching it to the high idle stop to get to full rated rpm. Get that done first, before worrying about the rest of it.