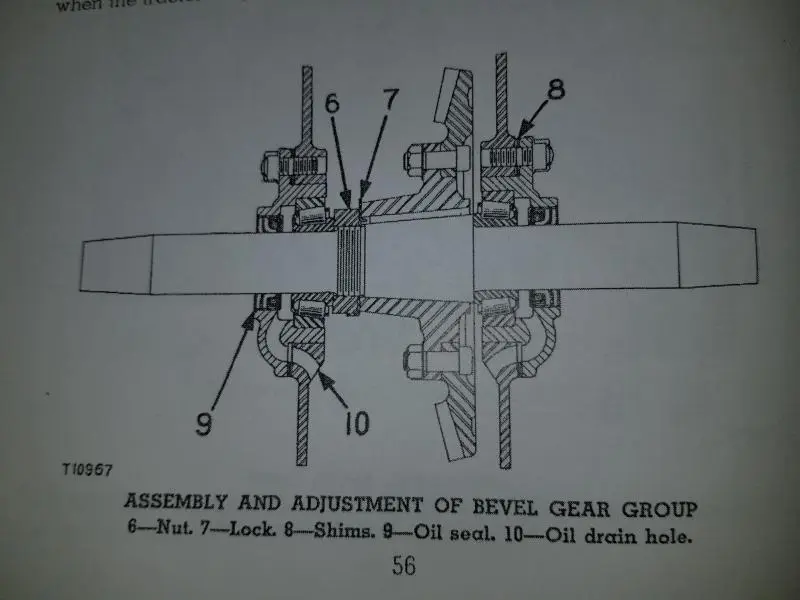

If one lever moves when the other is pulled, your bevel gear shaft bearings are shot. To replace them you have to pull both final drives, steering clutches packs, and the bearing retention caps. With your bevel gear shaft floating around, the pinion gear is going to get ruined. The bearing adjustment isn't just zero play, it has an additional preload to account for all the forces trying to move the gears out of place.

Should be three inches from the neutral position. I also have the brake pedals adjusted so there is four or five inches of travel so the linkages move more and don't freeze or tighten up.

I agree that the one stick moving forward when you pull the other is an ominous sign. You might want to take off a rear cover if you don’t have a winch or pto on the back and put a bar in there to push the bevel gear back and forth so you can see the actual movement and possibly get a look at the contact pattern of the pinion gear on it.

Thanks to everyone for the input. I don't have a winch or pto, so pulling the rear cover to take a peek shouldn't be too hard. Problem is, I may not like what I find. I put quite a lot of money and time into the machine already (a 5u). It has 24V electric start, glow plugs, new radiator core and decent tracks and uc. I was hoping to get some work out of it this summer, and put off any rear end work until next winter.

I guess I'm wondering if other people with D2's have similar play in the steering clutches, and how much is acceptable? Is this is something kind of common, but will need to be looked at after a while, or is any kind of play like that (indicated by one steering clutch pushing the other one back due to rear end wear) an indication of a disaster waiting to happen? I suppose the worst that could happen is the rear end might lock up an a really awkward place and I couldn't move the machine, which isn't something I would want.

I'll pull the cover and take a look at what is going on. It might be easier if I could eventually find another machine with a stuck (or no) engine and swap all my good stuff over to a rear end in better condition.

Might have to block up the rear or drain some oil though.

Per Rome, backing it up onto 6" blocks under the sprockets should be enough to stop most leakage from the bevel gear case if filled to the correct level. You can go steeper if you want but you want the brakes released to test the bevel gear movement, to ensure that there is no interference. Theoretically there wouldn't be when the clutches are released but it can hang up if there are wear patterns. Put a drip tray under there anyway.

Just looked up the spec. The preload is .017" shims removed. The shaft shifting means that at least .017" of wear in the tapered roller bearings, not good. If you can imagine the pinion being fixed, and the bevel gear tooth contact pattern moving all over. I have seen a few pinion gears with broken & chipped teeth. It is easier to change the bearings now, than the bearings, and finding a main trans shaft & trans rebuild later

Hi Team,

after running the unit up onto the blocks as described above, have someone look into the BG opening whilst some one alternately pulls each steer clutch lever back to load the BG shaft sideways each way in turn and have the person below watch for BG shaft side ways movement.

Cheers,

Eddie B.