Reply to ccjersey:

Marvin, I doubt the plunger can disengage from the rack. Easy to check though.......just take the cover off the side of the housing and check the dots on the plunger quadrant and the rack are aligned. Have heard Eddie B caution against tapping the rack with a stuck plunger because of the possibility of changing the indexing of the plunger gear quadrant to the plunger body.

I'm thinking the problem is related to the lock screw coming loose. Not sure the cylinder is threaded into the pump from the top, but from parts book, it looks like it is. The later U series tractors don't have that design with some sort of hex just under the nipple where the injector line screws onto the pump. I'm thinking it is either threaded in to screw up and down (changes the stroke length) or slides in and is twisted slightly to set the fuel delivery rate because of how it interacts with the helical passage machined into the plunger.

Need an expert to weigh in, I'm out on a limb and sawing for all I'm worth! Not sure which side I'm sawing on either😆

Hi Martyn,

second writing of this, other one lost.

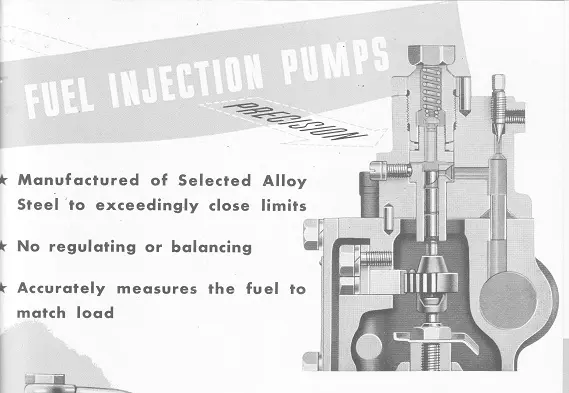

Study of the scan below may assist in following my dialogue.

Bear in mind that these pumps were designed and machined to not need any field adjust to replace an injection pump assembly/unit individually or other. They are ALL matched from the factory.

The screw holds the pump barrel in a factory set position. This being loose may allow barrel to be turned in the main housing if the pump seized and was forced around by pushing on the rack--as said above-- usually it is the pumps quadrant/sector gear that turns on the pump plunger in this scenario.

I suggest remove the screw and check to see if the indexing slot machined into the barrel is aligned or even the tip of the screw sheared off.

From the scan below you may be able to see how the unit is assembled. The locking dowel driven into the top of the housing, at the castellated nut, needs to be removed and the nut unscrewed to relieve the tension on the inner parts to allow the barrel index to be realigned by turning the barrel--maybe another pump would be a safer way to go depending on your ability to reset things.

If the quadrant/sector gear on the plunger has turned it needs a test bench and savvy operator to reset it by comparison of other pump units on your inj. pump.

Hope this helps.

Cheers,

Eddie B.