What kind of welding equipment is available to you; Stick, Mig, Tig, OxyActy.

Is your case cast steel or cast iron.

You need to drill holes at the end of the crack before you weld to keep it from cracking further as part of your prep.

When that crack gets hot, your gear oil is likely to thin and get into your weld, contaminating the weld. One trick to minimize this is to apply vacuum to the case so that air enters the case from the outside moving the oil away from the weld.

Just a few things to think about before you choose a filler metal.

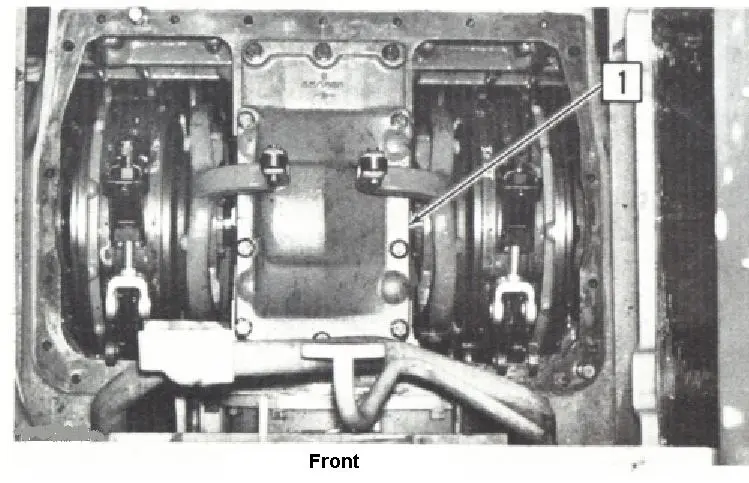

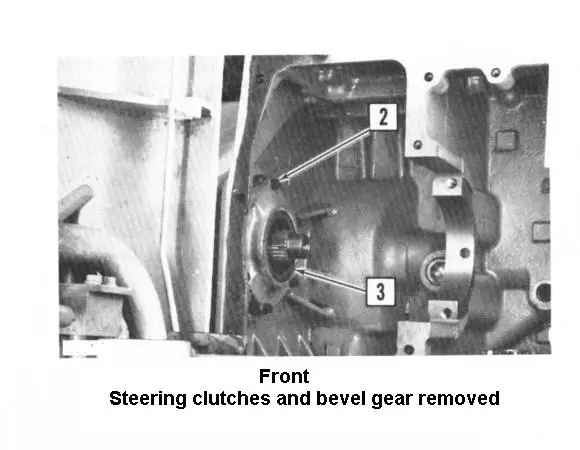

That is a job for an experienced welder for it to have any chance of success,that housing is cast iron and it welds very badly,you would need to find the reason for the crack,is it damage from hitting something,or is there something loose causing slap,it is an unusal place for a crack to appear,I have not seen it before,there are a couple of pictures from the manual of whats inside there.

Good luck

AJ

What kind of welding equipment is available to you; Stick, Mig, Tig, OxyActy.

Is your case cast steel or cast iron.

You need to drill holes at the end of the crack before you weld to keep it from cracking further as part of your prep.

When that crack gets hot, your gear oil is likely to thin and get into your weld, contaminating the weld. One trick to minimize this is to apply vacuum to the case so that air enters the case from the outside moving the oil away from the weld.

Just a few things to think about before you choose a filler metal.

[quote="Mike Walsh"]What kind of welding equipment is available to you; Stick, Mig, Tig, OxyActy.

Is your case cast steel or cast iron.

You need to drill holes at the end of the crack before you weld to keep it from cracking further as part of your prep.

When that crack gets hot, your gear oil is likely to thin and get into your weld, contaminating the weld. One trick to minimize this is to apply vacuum to the case so that air enters the case from the outside moving the oil away from the weld.

Just a few things to think about before you choose a filler metal.[/quote]

That sucks. If your case is cast iron it may not be repairable due to its physical size. Better to follow AJ's advice and find someone who has successfully done this before. Preheating that crack is likely to make the cast on either side of the crack harder, ensuring it will crack again. There's all sorts of people selling magic rod and methods to weld cast. Take AJ's advice and find a local welder who has done this sort of repair successfully to someone else's machine. There are no short cuts. My experience is in gas welding small cast parts which is not going to help you here.

Looks like you need to get the front support bracket bolts back in and tight on the track frame, all the stress is on the steering case from the track frame moving around. thats why its been welded so many times, youll just have a reaccuring problem with it.

remove the recoil spring covers and check the bolts on top of the front bracket to track frame also.

Good point.....

The front attachment wraps the top and side of the track frames but on these models it's an integral part of the loader frame...not the hard bar arrangement like on say the old 955's. Be a good idea to check the loader frame for breaks (and track frames) in that area.

I wouldn't give a chance in hell for successful repairs on that case. I see it as a new case or parts tractor.

Really nice 951. you nailed it OM, new (used) case or parts. Charlie