STEVEN,

Just and FYI. your other post, a duplicate, has been removed for you.

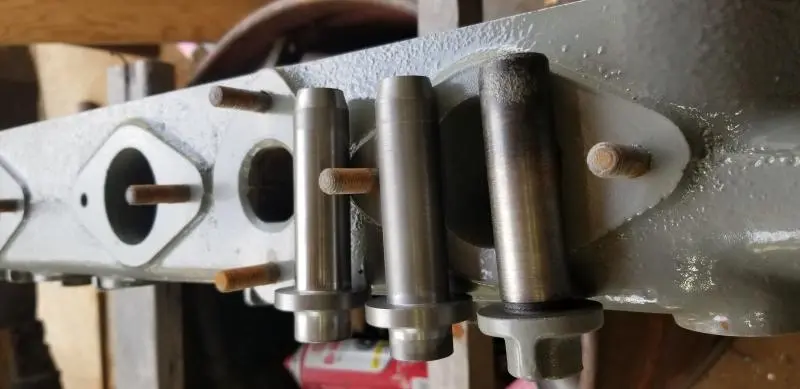

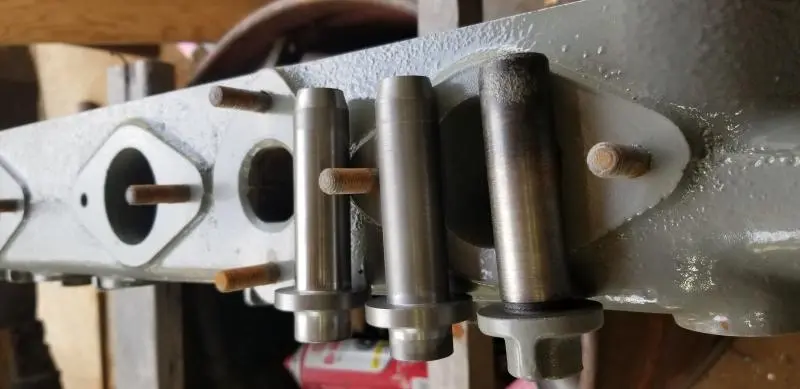

I made these two guides from 36" of cast iron bar stock, the rest I junked because I was working late at night & didn't have my head screwed on right. Anyway they went in well. I did make a few alterations, tapering the end for flow and turning a lead to get them started straight. [attachment=54073]20190525_151426.jpg[/attachment] One old guide showed .019" movement with a new valve so these will do nicely.

Those look really nice Stephen!! Good work.

BP.

[quote="Bruce P"]Those look really nice Stephen!! Good work.

BP.[/quote]

Thanks, I hope to get the rest made & the new valves addressed next week. This engine has been apart too long.

Ok, had a little excitement here today, got a new to me J&S wheel dresser in the mail for working the valve lock grooves. Got everything setup on the surface grinder and put in two lock grooves, so far so good but think I need a spinner handle on the rotating fixture. I also want to put in the narrow groove for the circlip in case a valve spring lets go one day.

I was going through the rocker shafts, not because I suspected anything bad, but just to spruce them up before getting new oil into the engine. Anyway, after disassembly I ran some solvent into the oil port and noticed that some of the rocker oil holes seemed restricted. The ends of the shaft were stopped up with core plugs, and after removing them, " holy Toledo " as grandpa used to say. The muck & sludge inside was incredible. Luckily I keep a good selection of tube brushes around and after some brush turning with the drill, all came up clean.

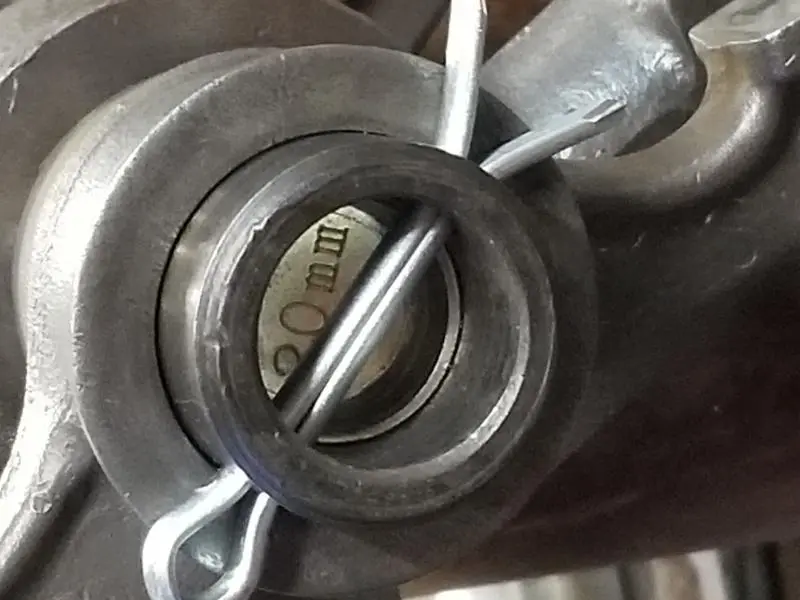

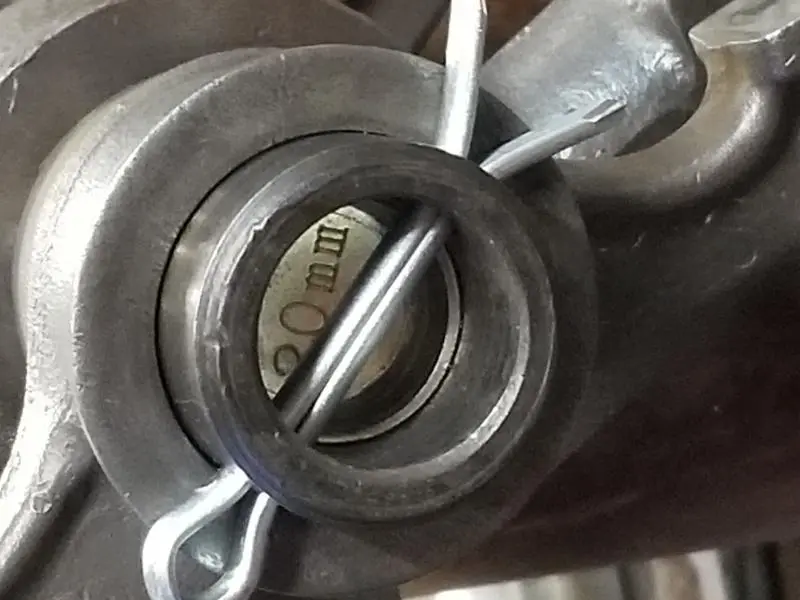

The core plugs were the odd size of 25/32 , the next size readily available was 20mm. I made a quick fixture in the lathe and turned a little off the OD. I really didn't check around much for the proper size because I needed some progress today. Anyway, everything worked out fine and I should be able to set the lash in the morning.

Hi Stephen, your handiness with a lathe goes to show how useful it is when dealing with old junk where parts aren't readily available. Maybe when I retire I can start acquiring some of those skills : )

Neil, I have a few machine tools with your name on them!

nice work I thought all spin fixtures had a speed knob on them. can you PM a price on a new set of valves as I got a thirty motor apart right now too and I see you'll all tooled up and set up. Don't Neil it's a trap machines are the easy part then you need time and well they take up space that could hold future projects. but the best part is you'll be the most popular neighbor around once word get's out you got a lathe. just a rule of thumb you will spend the same amount on tooling to make the lathe useful as you did buying the lathe. that's being said I am too far gone I got to mean future projects and a shop full of lathe and mills and a few stashed at a friends house too. did I mention there an auction sale this weekend?