From Repair Men's section of the Thirty Instruction book, form SL992, 9-28.

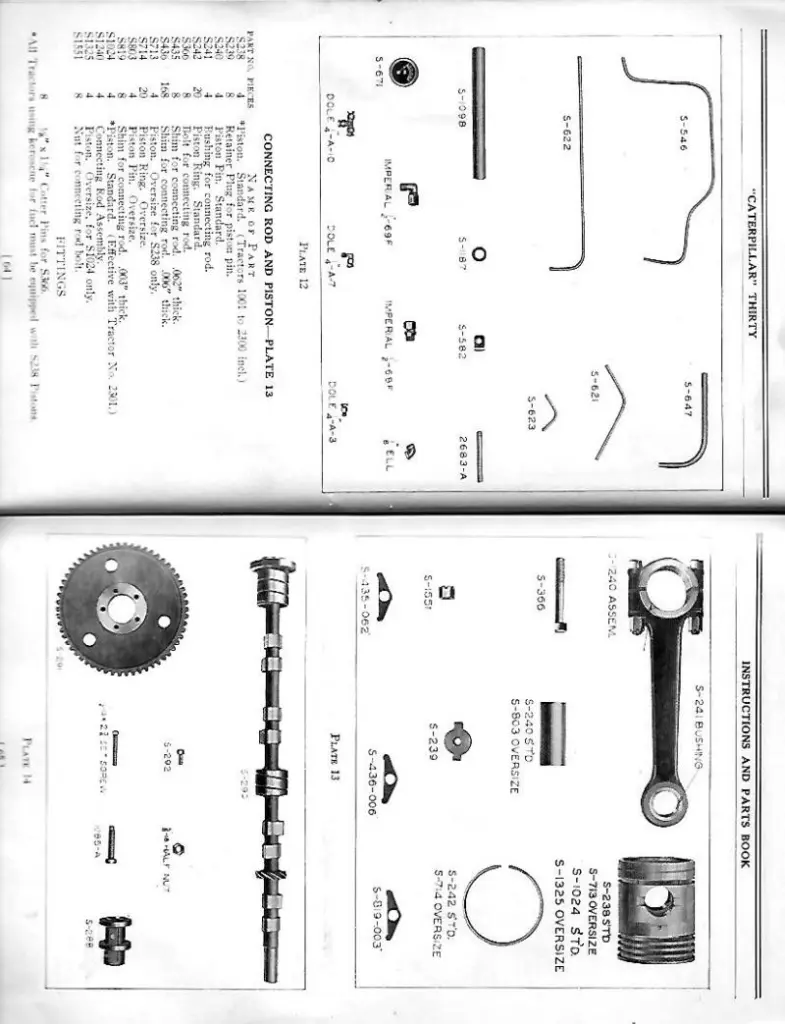

Thanks Josh for the scan though it doesn't say what the original thickness was and the parts book I have doesn't show that info either, though the diagram of the conrod in the parts book shows a very thick shim stack when new, looks like 1/4" or more, my conrods have a mess for shims and I can see the previous owner has removed some for other tractors he owned, some of my conrods have just a thick brass shim about 120 thou thick while others don't have the thick brass shim, just 3 or 4 thin brass shims.

regards

Mike

Mike, I have never measured the shim stacks but I would guess them to be .100" or better.

Looks like the original was, two of S-1733 shim per side, or two of 1A1038 shim per side, those numbers look to cross as well. The shims look pretty thick, but I can't find the thickness.

Thanks Chad and Josh, I agree those shims originally were thick, Eddie Bedwell told me once the Cat parts books were always to scale and using my digital vernier on the parts book comparing the journal size to the shim stack thickness I reckon the shim stack was around 0.220" - 0.250" when new, I just took some photo's of some of the shims I have here and they are all different but remembering these conrods might have been re-babitted once or more in their life time, the crankshaft in the tractor is 0.30" undersize from my rough measurements.

Thanks again

Mike

Hi Mike,

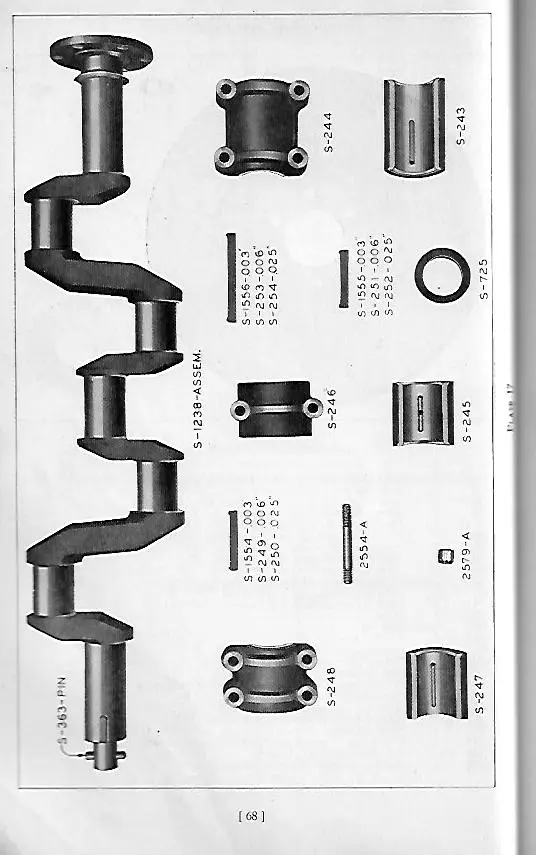

from my Best Thirty General Instruction and Parts Book, form SL193, is the following data I have for answer to your query--I have also included shim pack data for the main bearings too.

I am not saying these are correct for a Cat Thirty but it is the best guess and guide I can think of--it seems correct to me but I have been wrong before.

Note the number of 0.006" shims to be shared between each rod and cap--168--compared to both of the other sizes at 8 each or 2 per rod.

You can do the math.

Hope this helps.

Cheers,

Eddie B.

EDIT It is not essential that you have so many 0.006" shims if you are going to re-Babbitt your rods. They tend to be squishy and unstable. You can use some thicker shims to make the gap, but still do keep some thin ones for adjustment purposes.

The Cat update P/No's would be shim packs that are babbitt faced and tack soldered together so shims can be pealed off as needed. The babbitt facing being a close fit helps keep the oil in and stop the pack mis-aligning and shims getting jammed in the bearing clearance causing a tight bearing and damage--seen where it had happened to someone previously on one of my farm engines when I worked on it.

If all is well the bearings should not need adjusting again or too often on a show pony.

Your crank is likely under size so there will be a good thickness of Babbitt to wear and adjust up.

Hi Mark,

Thanks for welcome back--now the Boss has a new hip joint and has recovered extremely well and fast we can get back to helping out here.

Cheers,

Eddie B.

Hi Mike,

from my Best Thirty General Instruction and Parts Book, form SL193, is the following data I have for answer to your query--I have also included shim pack data for the main bearings too.

I am not saying these are correct for a Cat Thirty but it is the best guess and guide I can think of--it seems correct to me but I have been wrong before.

Note the number of 0.006" shims to be shared between each rod and cap--168--compared to both of the other sizes at 8 each or 2 per rod.

You can do the math.

Hope this helps.

Cheers,

Eddie B.

EDIT It is not essential that you have so many 0.006" shims if you are going to re-Babbitt your rods. They tend to be squishy and unstable. You can use some thicker shims to make the gap, but still do keep some thin ones for adjustment purposes.

The Cat update P/No's would be shim packs that are babbitt faced and tack soldered together so shims can be pealed off as needed. The babbitt facing being a close fit helps keep the oil in and stop the pack mis-aligning and shims getting jammed in the bearing clearance causing a tight bearing and damage--seen where it had happened to someone previously on one of my farm engines when I worked on it.

If all is well the bearings should not need adjusting again or too often on a show pony.

Your crank is likely under size so there will be a good thickness of Babbitt to wear and adjust up.

Hi Mark,

Thanks for welcome back--now the Boss has a new hip joint and has recovered extremely well and fast we can get back to helping out here.

Cheers,

Eddie B.

Welcome back Ed 😊👍