I'd be surprised if Jim didn't have those bits, but sit tight, you will have other folks chime in here soon I'm sure, looking to lighten your money clip for you😆😆 If you were to take those old valves to a good engine shop I'm sure they would source new ones for you, I did that recently with a 2 Ton head I got reconditioned, there are millions of valves available, they just need the measurements. Congratulations on freeing up that motor too, sounds like you have done a great job there.

Jims number is 641 9824207, or fax 641 9824297, he doesn't use computers.

Good luck

Mike

I broke the valve stem bushing on the #4 valve trying to get the valve out. I tapped the top of the bushing back to the proper height and the valve spring has about 1/4 inch of bushing to wrap around. Will this work or do I need a new bushing? I didn't see them listed in the parts manual.

Hi Cat10,

by my parts book form 4863 for PT1-Pt4929 the bushing is not shown but listed atop the T-575 Cylinder Block Assem. as # T-48. To get the Dealer to check this P/No you will need to convert it to a 6 digit No---thus T-48 becomes 0T 0048 for the computer to recognise it. I would also think it would update to a newer superceded P/No by now.

Others may have later numbers for you.

Cheers,

Eddie B.

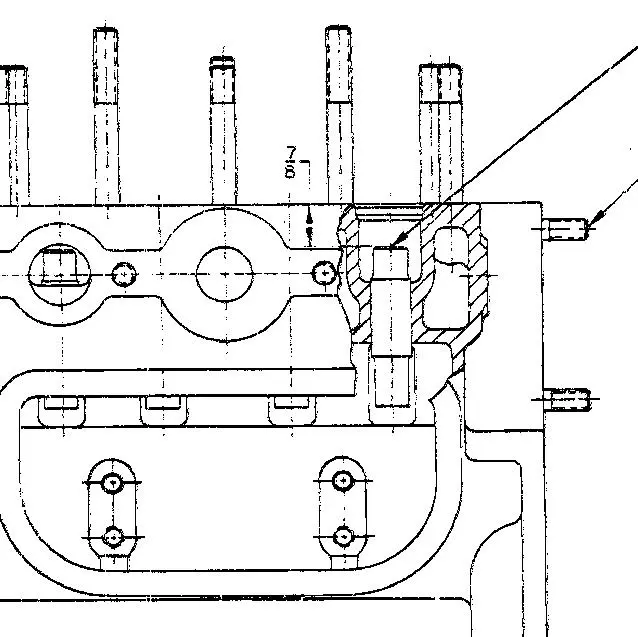

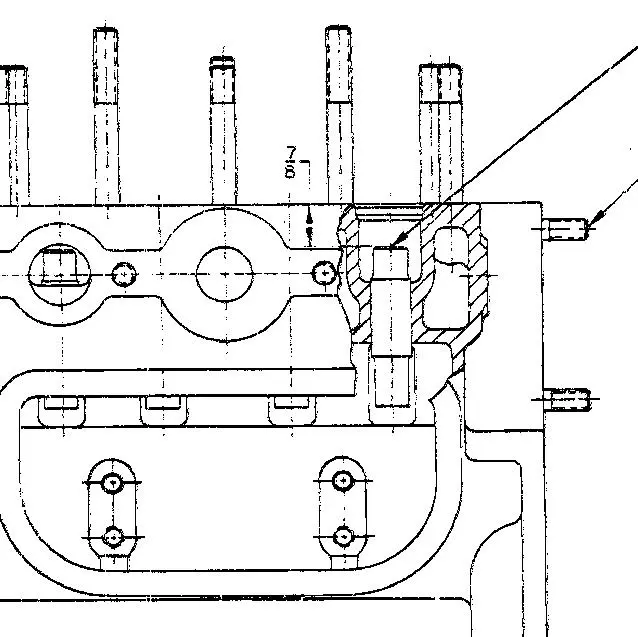

T-48 cross references to 1F-3287, but both are discontinued. From what you describe, it sounds like yours broke off at the transition from larger diameter middle part to the bottom segment. The bottom segment should be 1" long. So it's possible you have the part that was intended to position the top of the spring, just not as much guiding/protection for the valve.

[attachment=10395]Ten_valve_bushing.jpg[/attachment]

Yep, the broken piece is almost 1 in. long. There is at least 1/4 to 3/8 of the bushing that can still position the spring, so I think I can still make it work without pressing in a new bushing. Your thoughts?

Sounds like a job for JB Weld to me!!😆😆 A lot of the Yanks here rave about JB Weld, sounds so good you could build pistons out of it and get 10,000 hours easy!😆

I've tried JB Weld on a cracked RD6 pilot motor water jacket but I have yet to be successful with it, I mean it sticks fine and should hold that valve guide of yours if you follow the instructions, but the crack I'm working on seems to be getting longer every time I think I finally have the small crack covered. I thought originally it was about 2" long, but I think it is now closer to 6".

Good luck

Mike

[quote="Mike Meyer"]Sounds like a job for JB Weld to me!!😆😆 A lot of the Yanks here rave about JB Weld, sounds so good you could build pistons out of it and get 10,000 hours easy!😆

I've tried JB Weld on a cracked RD6 pilot motor water jacket but I have yet to be successful with it, I mean it sticks fine and should hold that valve guide of yours if you follow the instructions, but the crack I'm working on seems to be getting longer every time I think I finally have the small crack covered. I thought originally it was about 2" long, but I think it is now closer to 6".

Good luck

Mike[/quote]

Mike sometimes if you drill a hole at the end of the crack it will stop its progression, then fill with JB. Worth a shot?

Regards Dennie

[quote="64farmboy"]Mike sometimes if you drill a hole at the end of the crack it will stop its progression, then fill with JB. Worth a shot?

Regards Dennie[/quote]

Thanks for that tip, trouble with this crack is I can't see or get to the end of it because it is hiding behind the valve spring. It doesn't leak hardly at all once the motors are running and warmed up, but after I shut her down and go to start her in 2 or 3 weeks time I find half a pint of water in the pilot motor sump.

I'm starting to think the easiest, and cheapest solution will be to do nothing, and just remove the pilot motor sump plugs at the end of the days driving and dump the oil, allowing any water to then escape over the next few weeks or months between drives. I do finally have my Alumaseal coming in from California soon, so I look forward to trying that, but I don't hold much hope.

regards

Mike

[quote="Mike Meyer"]Thanks for that tip, trouble with this crack is I can't see or get to the end of it because it is hiding behind the valve spring. It doesn't leak hardly at all once the motors are running and warmed up, but after I shut her down and go to start her in 2 or 3 weeks time I find half a pint of water in the pilot motor sump.

I'm starting to think the easiest, and cheapest solution will be to do nothing, and just remove the pilot motor sump plugs at the end of the days driving and dump the oil, allowing any water to then escape over the next few weeks or months between drives. I do finally have my Alumaseal coming in from California soon, so I look forward to trying that, but I don't hold much hope.

regards

Mike[/quote]

This sounds like a plan to me, I've seen guys do a $5000 motor rebuild because they were burning a $3.00 qt of oil every 1000 miles.

Good luck keep in touch

Regards Dennie