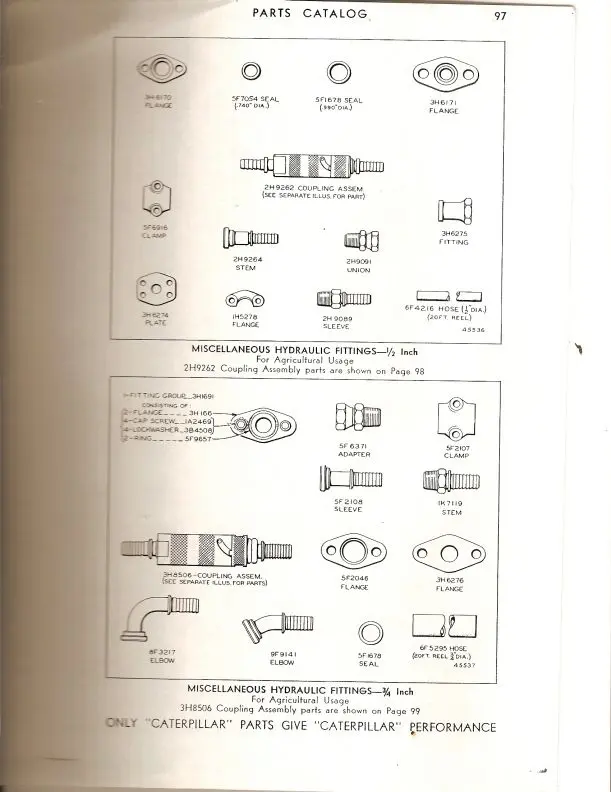

It's been a while since I checked but I believe its "code 61" fittings that will fit the 5f2046 flange.....regular 2-wire 3/4" hyd. hose works fine.

I beleive that these are code 61 flanges and in the past I have taken the old flange halves ( the part the bolts go through ) & if you only have a flange on one end. You can crimp the code 61 flange fitting on one end & then slide the flange half over the sleeve, then crimp fitting on the other end.

Also I have been in some shops with old inventory & have seen some of these fittings but they are designed for 4 wire hose ( XT3 CAT hose ). So maybe contact your local CAT dealer & find out if they have any old inventory still kicking around

But if you still have all the fittings & sleeves any 2 wire braid hose will work for example: Parker 301-12. Good luck hosing if you have any more questions let me know.

Thanks all for the input. I found that Cat calls them "captive flanges" in thier

catalog. I ended up using Parker 302 hose due to one hose was made years

ago with parker series 30 reusable (which the two hole flange is no longer

available) I stayed with the the orginal cat two pieces on the others.

The partsman at Cat told me that Cat pricing was comparitive to Parker

but I did'nt compare specific prices. Nice to know for future reference.

Seems like fittings have a bullseye on them. I scraped a tree last year and

the knotted burr was a direct hit on a blade cylinder fitting. It snapped like

a tooth pick.

If you need some 3/4" two hole flange fittings let me know I may be able to help.

for 3/4" lines, a standard 2-wire (SAE 100R2AT) hose works fine, and many shops also crimp Code-62 flange ends onto 4-wire (R12) if you need higher pressure. But your hunch about the Cat 5F2046 “barb flange” is right—Cat’s flange (“Super-Cat”) is dimensionally like Code-62 but thicker at the head (dimension C), so a straight Code-62 clamp/half often won’t seat correctly even though the bolt pattern matches. In practice you either use the Caterpillar-specific flange/clamp for 5F2046, or a supplier’s “Cat/Super-Cat” variant; some folks report Code-61 hardware mating to 5F2046 on older Cats as well. Bottom line: pick 3/4" hose spec for your pressure (2-wire or R12) and pair it with Cat/Super-Cat (or verified-compatible) flange halves rather than a generic Code-62 set.

Mark

use sae 100r2at hose with the cat reusable ends. the common size being dash 12 in other words 3/4 hose. (a dash is equal to 1/16th of a inch)

they are code 61 NOT code 62!

modern code 61 clamp flanges are 2 piece and 4 bolt instead of 2 bolt. keep the original flange plate and use new hose ends if required just remember to fit the clamping flange over the hose end before installing it to the hose.

the modern day cat code 61 fittings and flange plates as supplied currently by cat are thicker and need a spacer when using the vintage cat hose fittings and any other brand. i dont know when cat started using a thicker flange just that they do. or so my hydraulics service tells me. id say part of it is to allow higher working pressures modern day equipment has.

these old girls only worked at 1200psi part of why the cylinders are so large compared to the working capacity of the machine(more piston surface area means more working capacity for a given pressure.)

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality