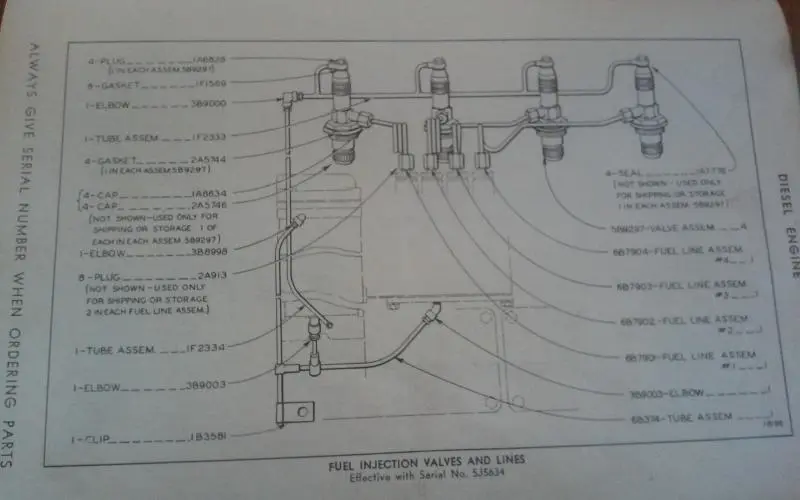

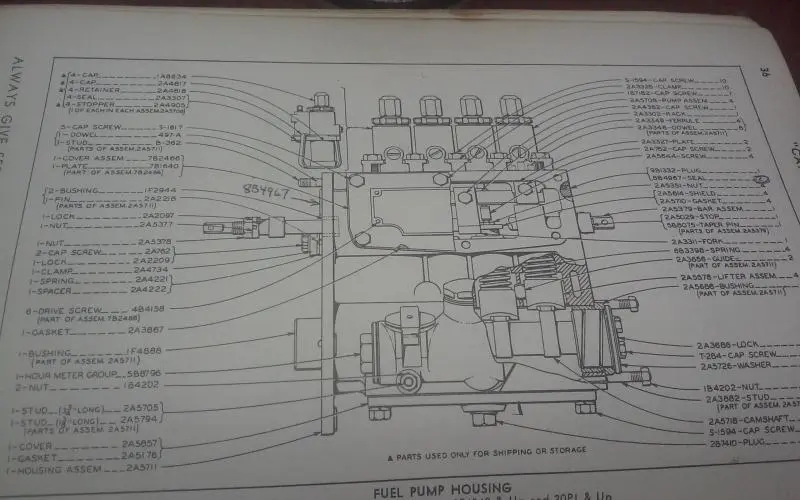

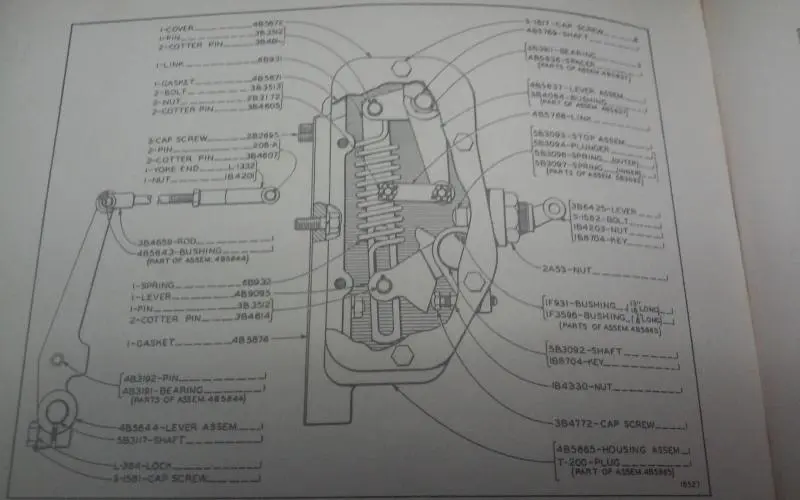

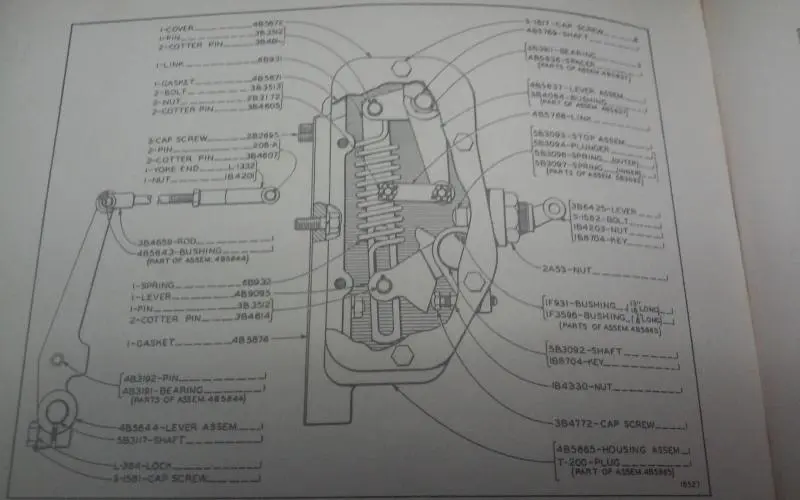

Pretty simple mechanism, but a little rust or wear can screw it up pretty easily. What is it doing wrong? Pictures are from 5J3501 up book

Wednesday December 2, 2015

Hello ccjersey,

Thanks for posting those diagrams. The problem is oil buildup in this compartment. Yesterday I removed the six bolts and cover-plate (P/N 4B5672) and drained about 1/3 cup of rather clean oil from this compartment. I understand that this compartment should be dry and am wondering what is the source of oil intrusion. Do you know what might be the source of this problem? I was investigating this area of the tractor in preparation for removal of the clutch and starter pinion. This tractor has been in our family for over fifty years and has been stored indoors for over twenty years. It was originally used in a citrus orchard to pull an offset disc and spring-tooth. It operates but needs some attention at the clutch and starter pinion. The original serial number is 3J1813SP but the engine was damaged in the 1960's and replaced in the 1970's with a 5J engine. This early model tractor has no access plate for adjustment of the pinion latch. My plan is to remove and service the clutch and starter pinion assembly and then drill my own access hole for pinion latch adjustment and fabricate an inspection plate to cover the area. Thanks for your help.