Hi Team,

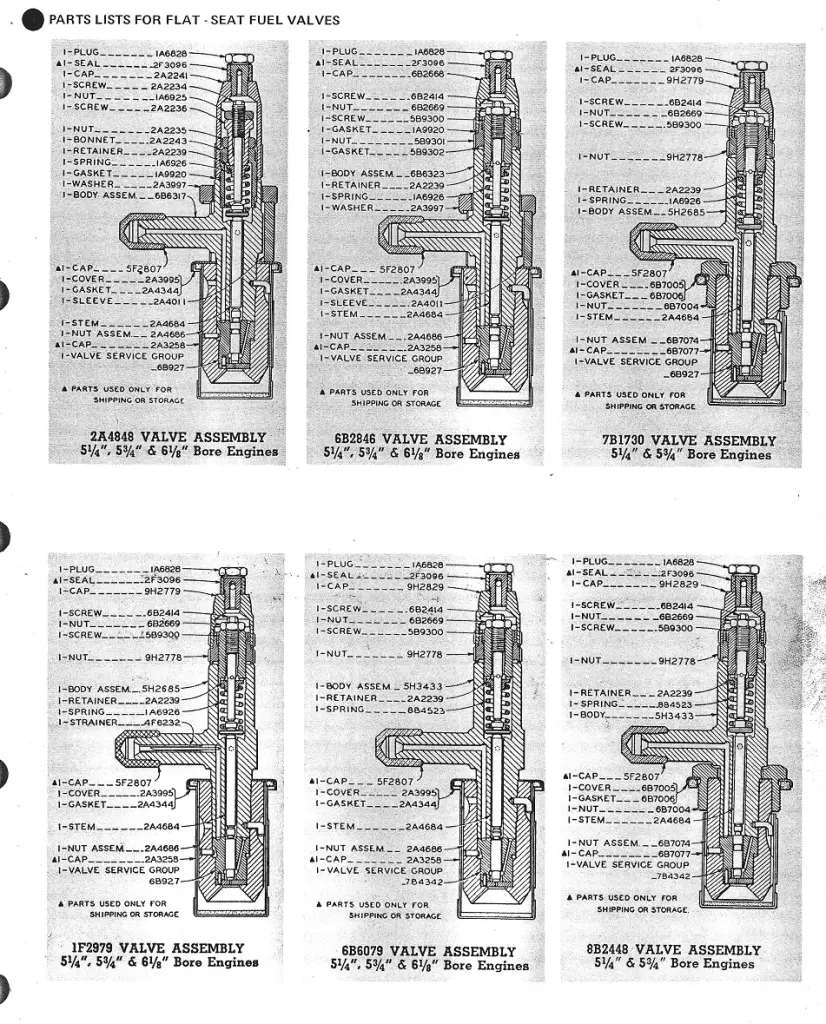

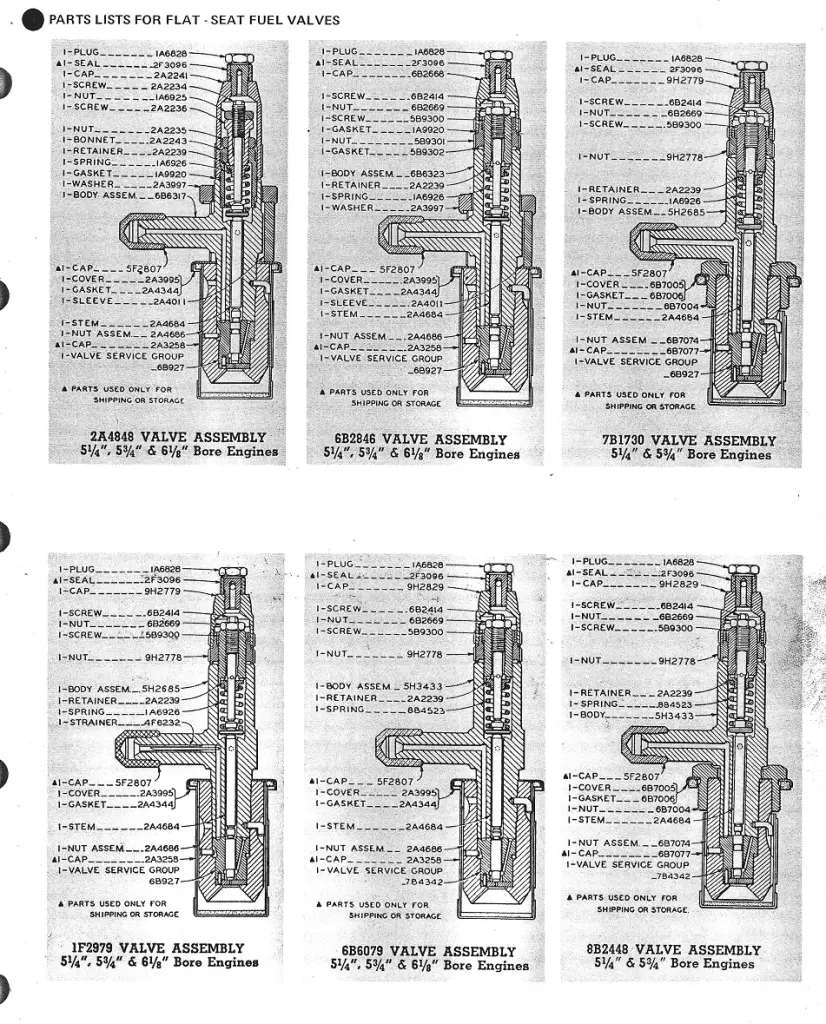

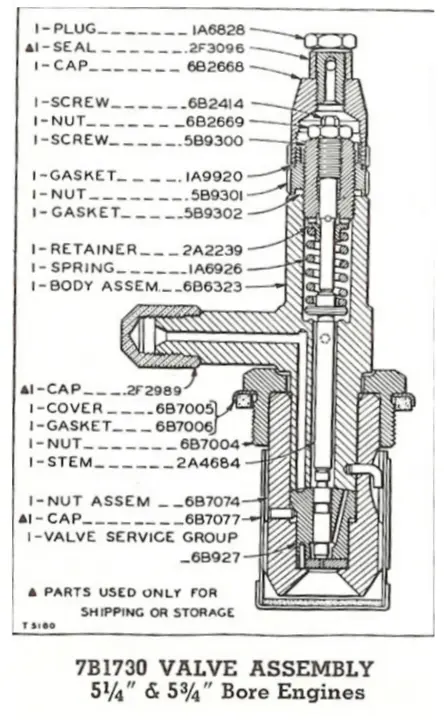

sometimes a few raps with a soft metal drift on the retaining nut top and available flats, side on, can loosen the rust--as you can see in the scan the clearances for dirt and rust buildup are close but not usually so close as to be a great issue unless the engine bonnet had been off and or the cork gasket under the dirt cover/shield has been damaged and /or missing then it gets harder.

About the only parts available would be the cork gasket and the copper washers for the drain line banjo bolts these days.

Cheers,

Eddie B.

Raccoons will leave a nice pile of $#% on top of the injectors and really turn everything into a real rusted up mess.

Are you working the retainer nut with the proper cut away socket? Not the chisel method I hope.

Hi-

Thanks for the reply's. I have the correct cutaway socket. I also made a conversion tool so I can use my 3/4 inch drive impact wrench. I have heated with a propane torch (fear of damage from acetylene), I have taped with a hammer and ball-peen hammer on teh flats. I have soaked in Kreil oil and I have taken off the valves and valve cover risers to allow more rotation of the injector nozzle. This allows for 2/3 of a rotation before the nozzle nipple hits the head bolts. When turned to the max I have tried using a block of wood and hammer to drive the injector nozzel down ward in hope of separating it from the nut.

I have all the parts except for a new nozzle. I am trying to replace the o-ring on the precombustion chamber since coolant is leaking out around the injector.tube and nut. I am out of ideas. Any thoughts. Thanks

At this point I am worried I will have to pull the head in order to remove the nut and injector tube in one piece. Anything short of that would be an improvement..

Can you post a photo of that injector nozzle?

Can you remove only the head bolts that are in the way? Even better if they're studs; you can back the entire stud out by jamming two nuts. Would that give enough room to spin 360?