www.cat-cave.com

Wow! You men are Masters!

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

www.cat-cave.com

www.cat-cave.com

www.cat-cave.com

www.cat-cave.com

www.cat-cave.com

www.cat-cave.com

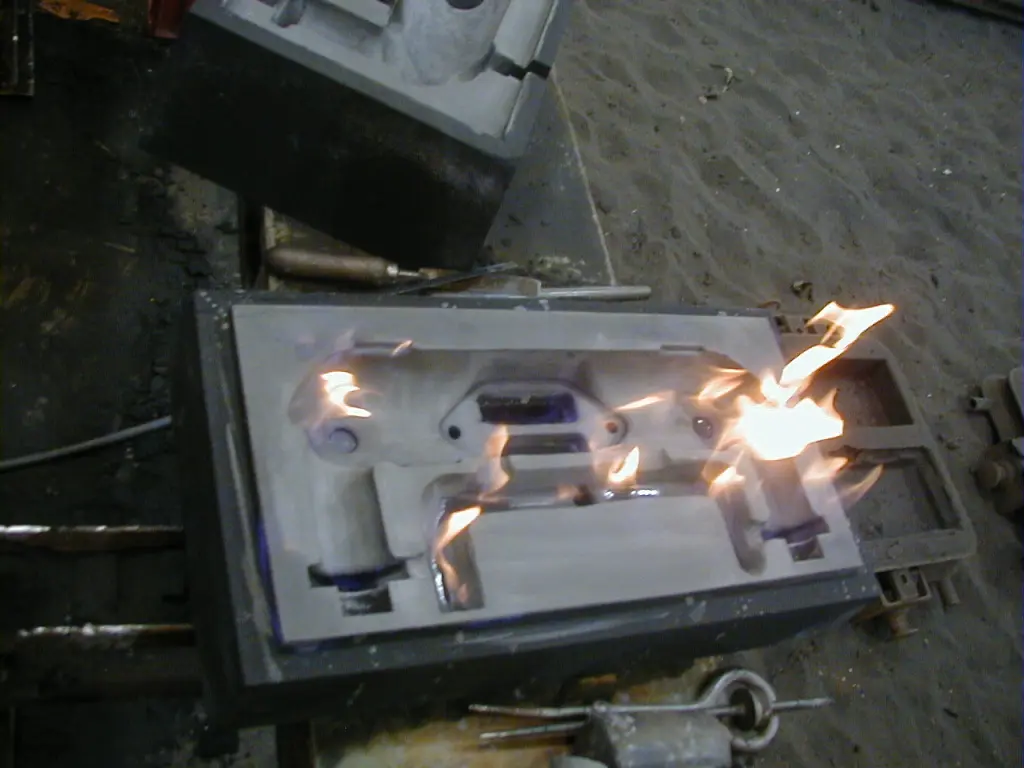

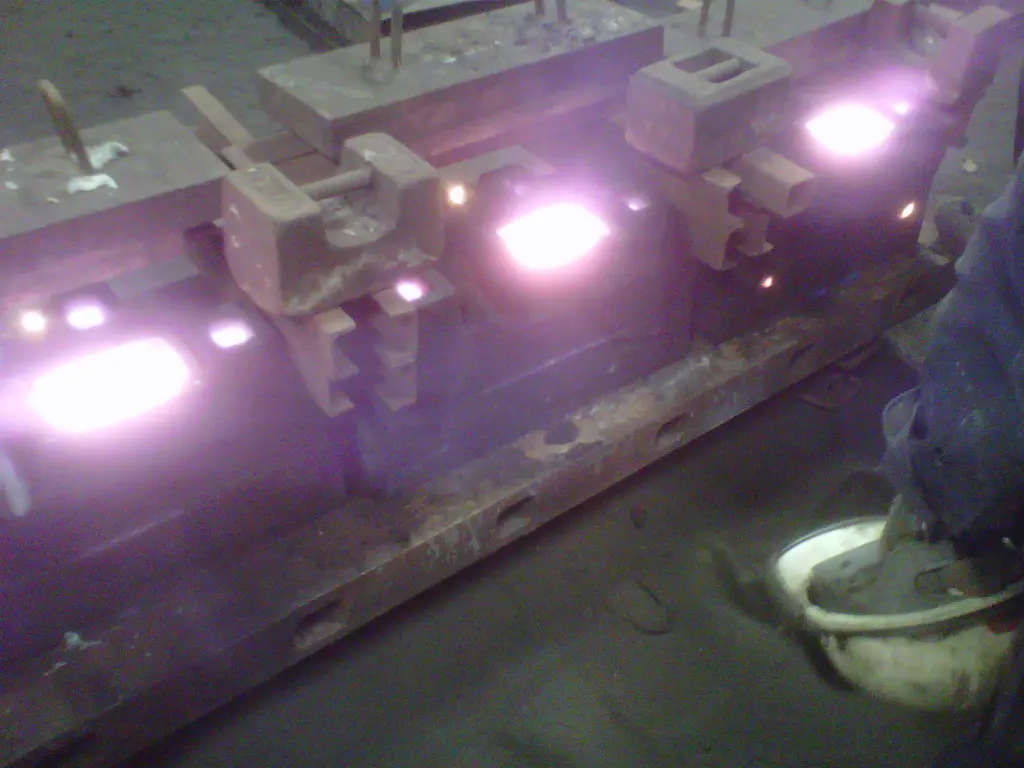

The morning after the Pour. Using the overhead crane and chains to remove the weights and steel girders. Out of the Sand Pit to the Knock Out Area. Yeap using a Sledge Hammer to remove the Sand to Find the Raw Casting. Then using a Small hammer. Hammer the Casting to break up the sand inside the core jacket and Poke about inside the Core Holes to get sand out. Then Load into Shot Blaster. Fettling Up with a Grinder then Machining Up. Followed by a Pressure Test on the inner core to check ALL GOOD. High Temp Alu Foundry Furnace Coating. Box up.

CM

[attachment=73203] Big Hammer (1).jpg[/attachment] [attachment=73204] Big Hammer (2).jpg[/attachment] [attachment=73205] Big Hammer (3).jpg[/attachment]

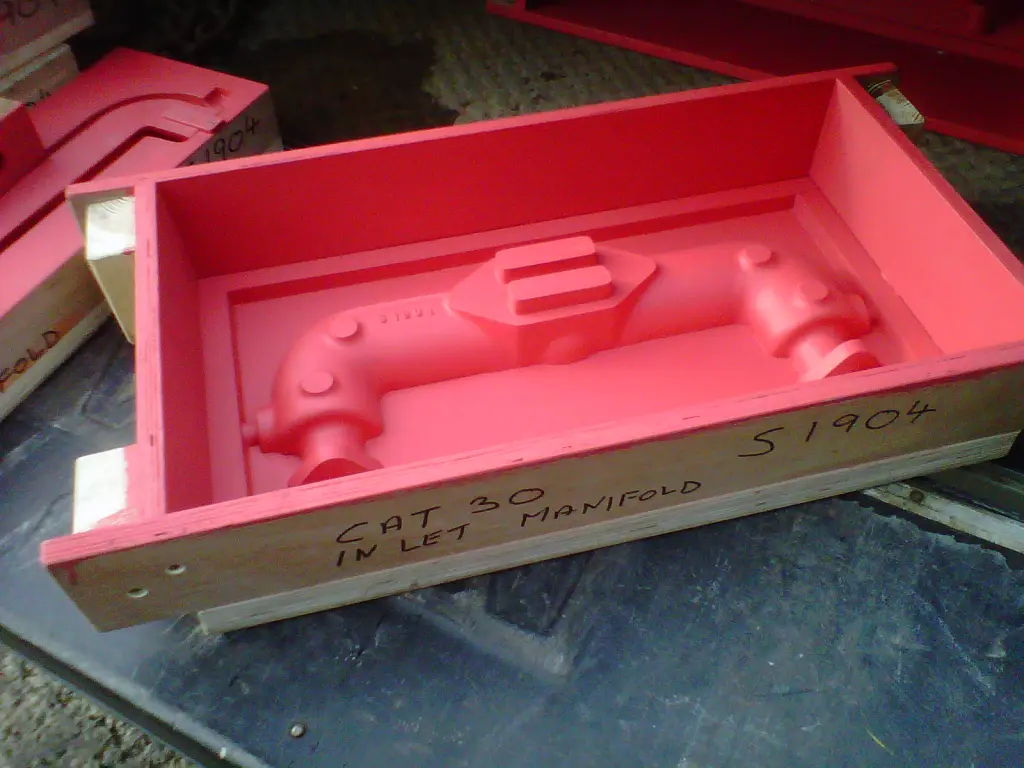

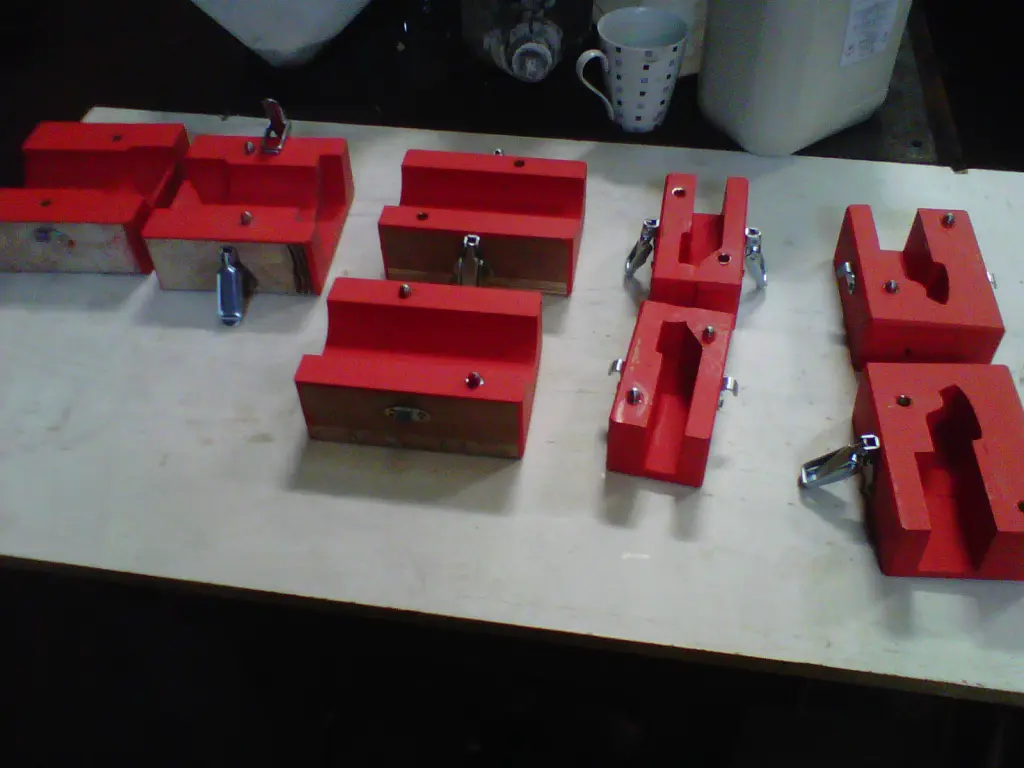

Cat Cave castings are the Best quality ever pattern making is truly painstaking work my dad was a pattern maker and he would talk about his workto be able to make the pattern for the mold and have to size it for the shrink of the molten iron his work was always to plus or minus one thousandth of an inch he would hand sand the piece by hand

www.cat-cave.com