you have a broken spring which may or may not be part of the problem.

Get some closer pictures of the track.

The adjuster slug can usually be repacked without removing the track if it's wore out enough.

Don't try it with the track half off.

Get a picture of the other idler.

Bob

you have a broken spring which may or may not be part of the problem.

Get some closer pictures of the track.

The adjuster slug can usually be repacked without removing the track if it's wore out enough.

Don't try it with the track half off.

Get a picture of the other idler.

Bob

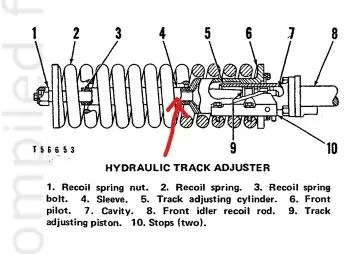

Pardon my ignorance here, but when grease is just coming out the back of the cylinder and its not tightening the track at all, does this mean the seals illustrated in the picture below are bad? Or is it also possible that something is seized up?

[attachment=77274]1.JPG[/attachment]

Need better pictures but it looks like something is cobbled up with the right spring.

Get pictures of both sides,

Count the number of pads on both sides,

See if those tracks have master links.

Bob

My brother in law and I had a very productive day. we used a chain and the lifting arms of the 977L to lift up the track enough to allow for large steel pry bar to put the track back on the idler wheel and rollers. Then we used attached the chain to the bucket and curled it to pull the idler forward. It moved forward almost 4 inches. From there we pumped grease into the track adjuster to see if it would hold. To our surprise and delight the grease held and began to push the idler forward after pumping in a good amount of grease. Drove the machine all around and the idler stayed in place and its holding grease. I didn't manage to take pictures until after we got the idler pulled out but see below for pics. Feeling blessed and lucky today!

[attachment=77275]IMG_2359.jpg[/attachment][attachment=77276]IMG_2357.jpg[/attachment][attachment=77277]IMG_2356.jpg[/attachment][attachment=77278]IMG_2358.jpg[/attachment]

I joined just now, as I searched for answers to a similar problem.

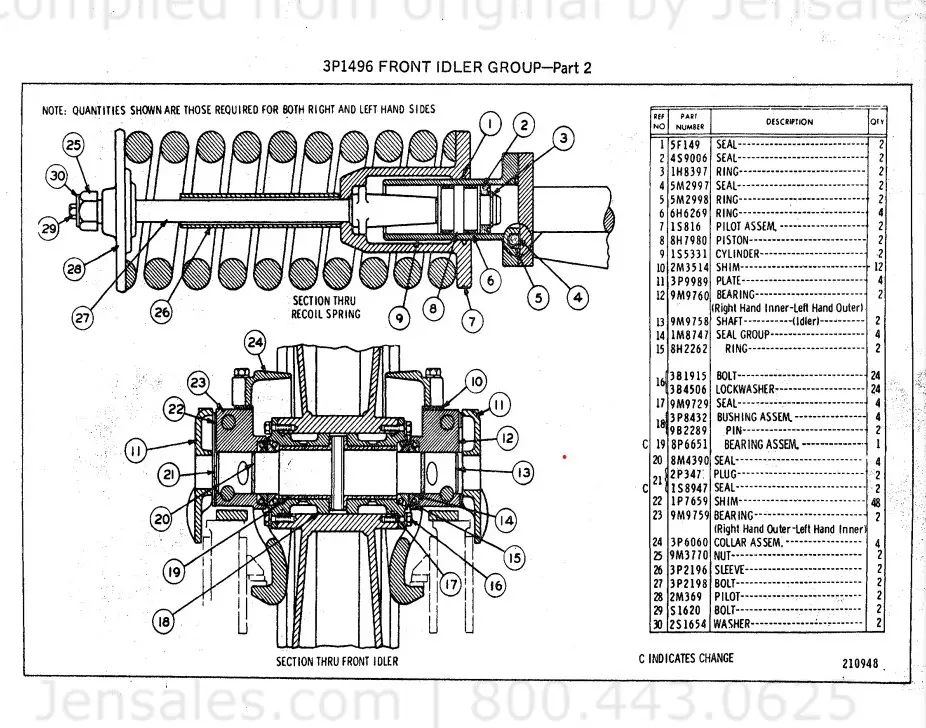

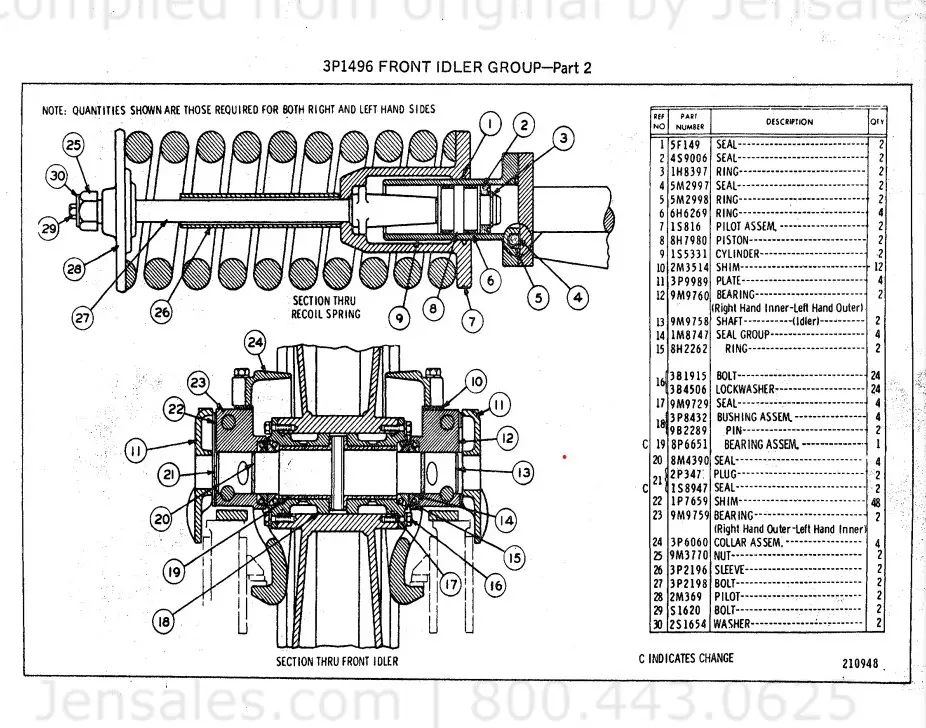

My "new to me" 1972 977L is also leaking below the track adjuster/grease fitting. Squirting grease out, as I pump it in. My mechanic, said the seals were pretty easy (his words), and is scheduled to replace them next week. However, I know those springs are called "widow makers" so I'm assuming the seals aren't involved with spring removal.

My springs are both cracked in the same place as yours. Been that way a long time says the mechanic (as he's worked on this 977 for the last 30yrs).

I'm going to try your solution to pull the idler forward.... not for a perm fix, but to see if we get movement as I think the seals are just old and probably a bit 'hard'. My 977 has been sitting with no use but to be started and moved around a yard for the last 8yrs.

I also got a 931B (both with 4-in-1 buckets), so I'm pretty excited to put them to work on my property.

my father-in-law standing beside my 977L with the "loose" track

That track is junk. You need to short a link for a temp. fix so you can adjust your tracks.

Your adjuster piston maybe out too far.

Bob