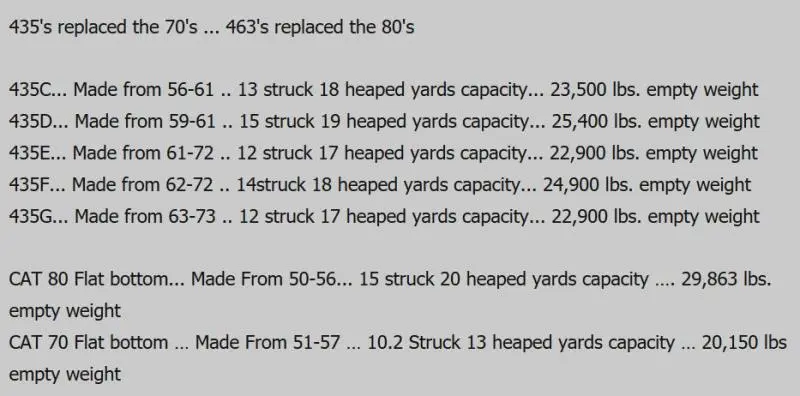

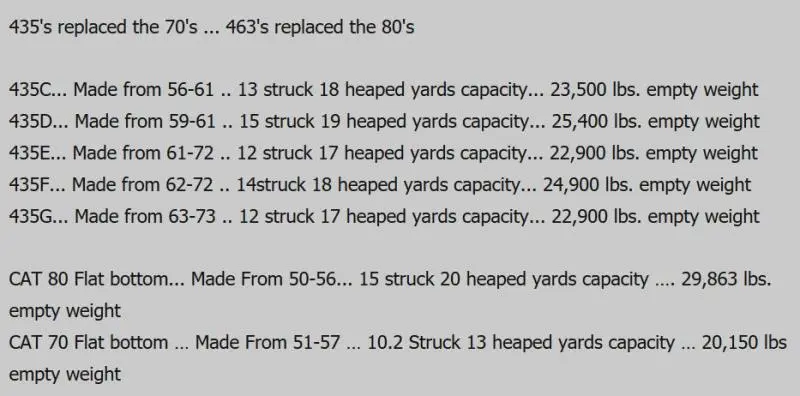

No seat time but the 435's replaced the #70's. I'd think it would work fine.

Run 435's for years, good scraper, Made for the D7D,E, F and G. Some series had high side boards and some low or tapered. Try to get a #127 or #29 cable control, the "live" power one, faster drum speed to unload and bowl lift than the #25. In heavy clay a pusher does help but if extend the middle stinger [cutting edge] and cut about three inches she loads really good, the thinner you cut the better the dirt polls in and fills the bowl and unloads better also.

56C and 83F series comes with 13 tooth pinion and 30 tooth gear

31E series (more common) comes wit 16 tooth pinion and 30 tooth gear

Rome/KG, what would you recommend?

I have a #29 unit 56C series on mine.

Thank you both for the input. I have a #29 here, I will have to check the series on it, not sure which it is but it came off a D8H I think it was. I have 2 other pull scrapers one Cat and one Bucyrus Erie, just think this would be a nice piece to collect is all, and I have a bit of work I'd like to do with it.

What’s the specs on the high horse? Any pictures?

1969 model year D7E with angle blade and full cab, Hyster D7J towing winch with fairleads on it now. It came out of a gravel pit where it pushed overburden off most of the time, not too terrible of a life. Needs a few little things, pony start, power shift. I have a few pictures here. I use it on small projects around the house.....

Nice Cat 👍

I’ve only operated Pops old D7’s and my 17A draw bar only pulling a can. They sure were easy and balanced, little slow and underpowered. With your D7E having more HP and a big winch on the back must make for well balanced enjoyable machine to operate.

We all heard about your scraper operating.....Glen made sure to poke your ribs enough when the subject came up, lol. I forgot to say the HP on the High Horse D7E is rated at 180 according to the book, should be enough go to go around I suppose.

Rome/OM, My cable control is a 31E series, should that have any bearing on things? With a 16 tooth versus 13 tooth pinion it would hoist in a bit faster given the same input shaft speed right? Probably use a bit more power too in the process. Thoughts?