Hi Rob,

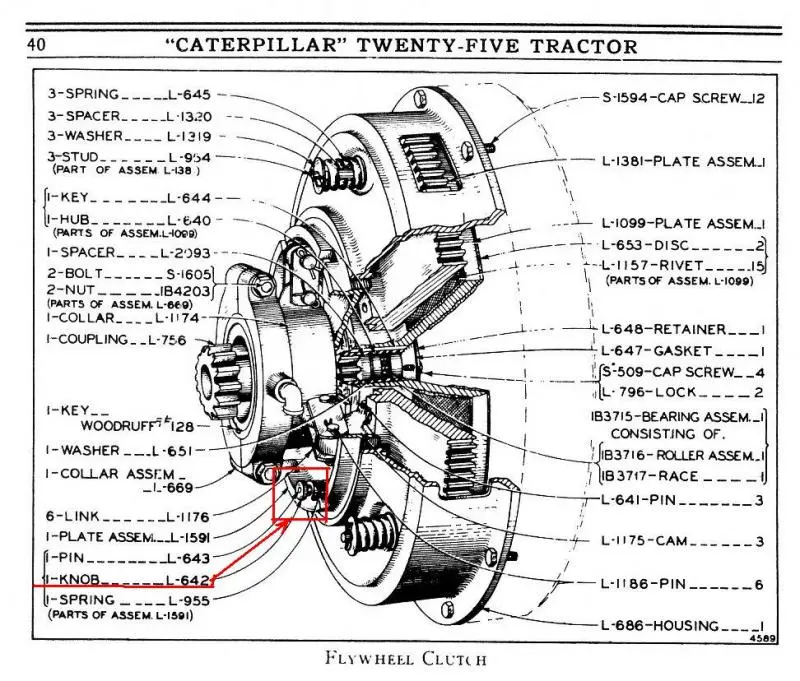

Scan below may help.

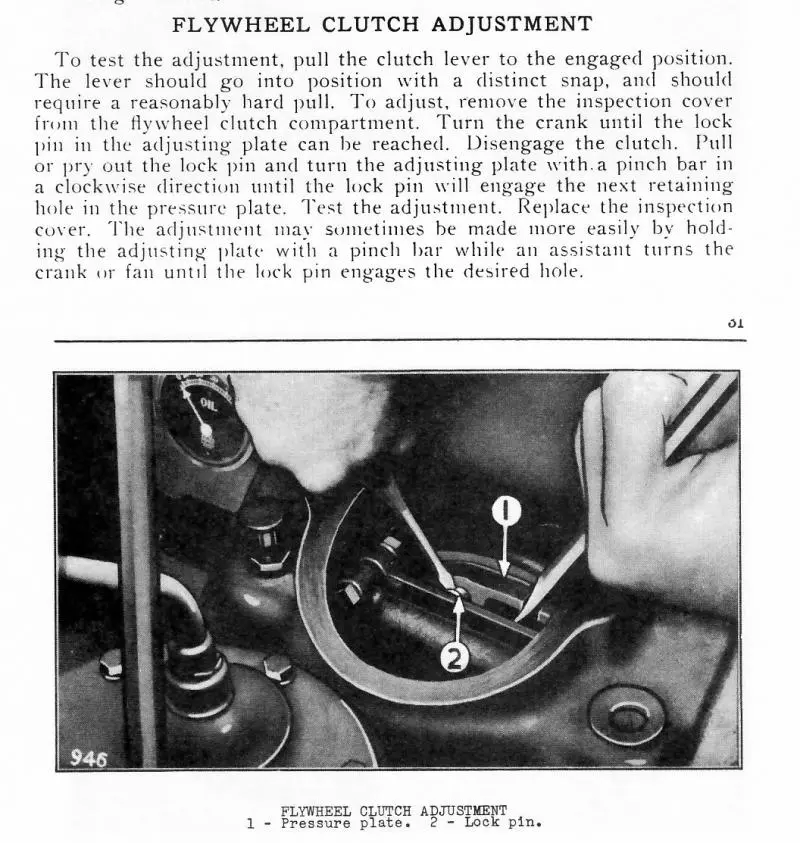

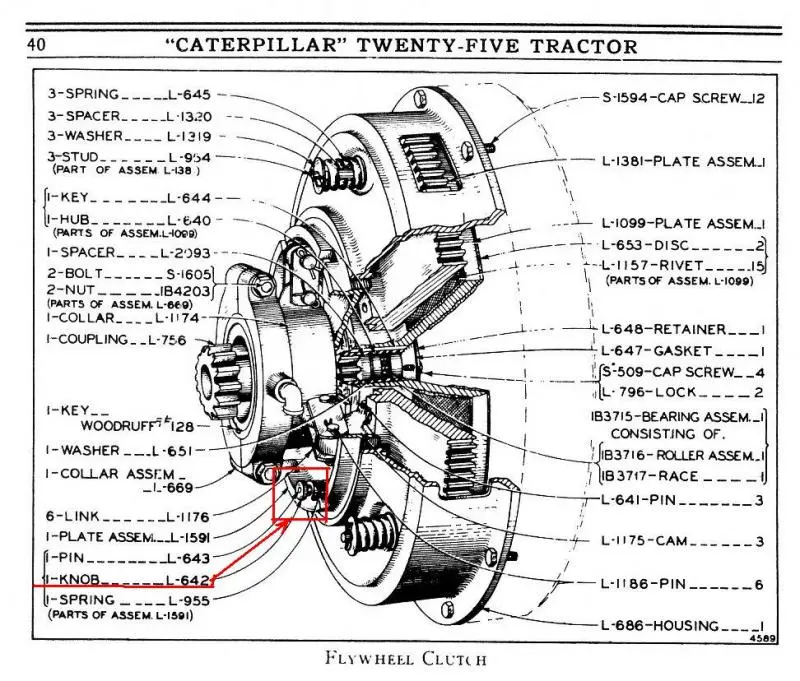

Remove clutch compartment cover. With the clutch disengaged, turn the engine until the lock pin plunger head appears, lift the head of the pin to disengage the lock pin and rotate the centre plate clockwise until the lock pin will engage the next adjustment hole. Test the adjustment, and repeat as needed. Refit the cover.

Hope this helps.

Cheers,

Eddie B.

Eddie B.

Thanks, I'll print the page and compare it, but for some reason it doesn't look the same. This one has a adjusting ring and you can see its been beat on some but they were turning it counter clockwise. And it has two pins with springs and washers on top with cotter pins locking them on. The springs pull the pins back so you wouldn't be able to pull on the head of them like your picture shows. There are two of them so I don't know how you could get to both at the same time. Oh well I'll take a look.

Thanks,

Rob

Hi Rob,

have never seen or worked on one of these jiggers, namely the 4F S/No 28 tractor.

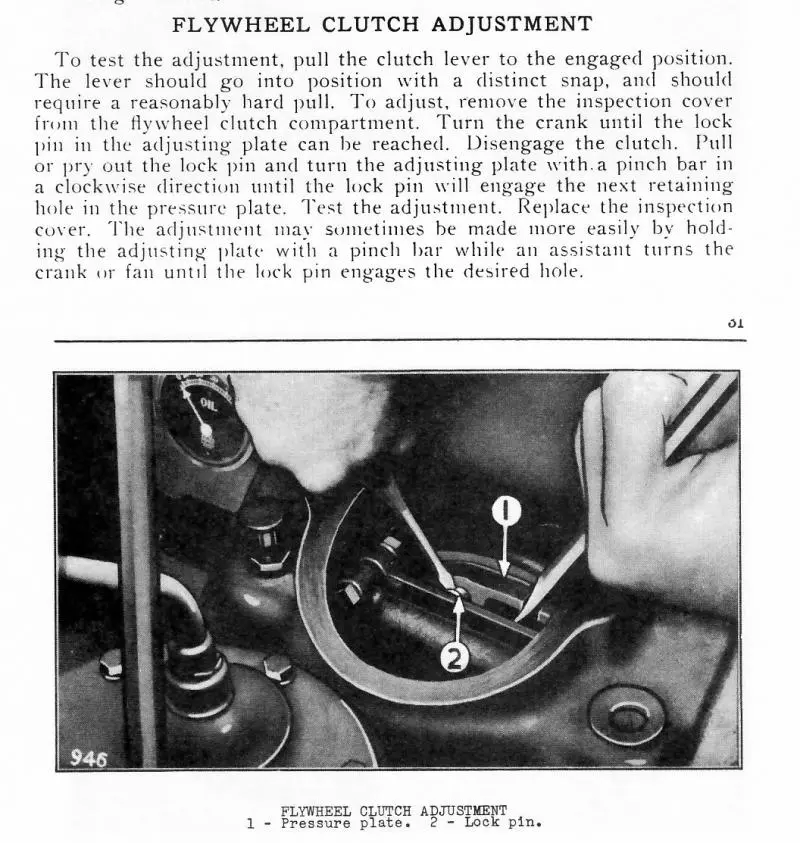

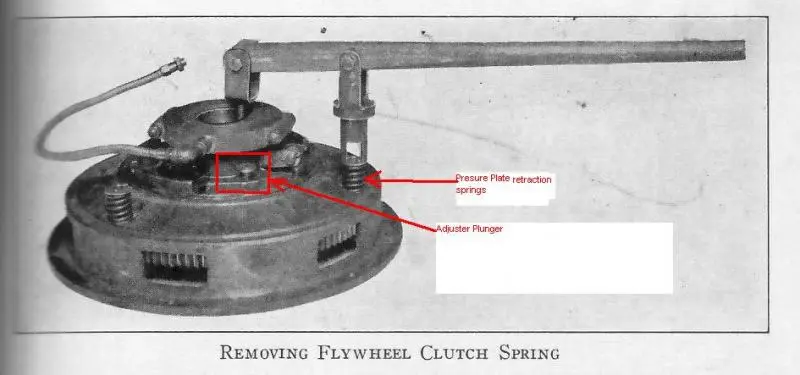

The scans below should clarify the springs with cotter pins etc are the 3 pressure plate retraction springs.

Outlined in both scans is the adjuster plunger in the centre section of the clutch cover/adjuster ring.

If your clutch is different I am at a loss to help further.

The parts scan is from my 25 tractor Parts Book and the other scan is from Serviceman's Reference Book

for the 28 tractor.

I believe that the 20, 25 and 28 are basically the same machine in different Horsepowers--I stand to be corrected as the Operators book covers all three machines.

Hope this helps,

Cheers,

Eddie B.

Eddie B.

A big thanks, your picture was exactly what we have. The adjusting ring was frozen but we backed it off 1/4 turn and then tightened it up. That did the trick the clutch did fine then and we got it down to the barn to finish up. Even the magneto started to work a little but it's still weak so tomorrow we'll fire it up again and warm it up with a heat gun to dry it out. Wish I'd had a camera the owner look like a kid as he pulled away on it. As soon as we get it fully running he also has a D4 we need to pull off. The pony motor is not wanting to start and it's out in the brush on the side of a hill.

Thanks for all the help,

Rob

Hi Rob,

thanks for the update of your success.

Glad the adjuster succumed to your efforts.

Hope the maggie dries out and does what it should.

Most maggies respond to a good cleaning of the points surfaces to get good electrical conduct thru them. Also a de-dust of the distributor area helps as well to stop cross firing or shorting to ground of the high tension sparks.

Good luck.

Cheers,

Eddie B.

Eddie B.

Thanks for the suggestions, the points have been cleaned and the secondary systems working. But it starts to miss when we change over to the magneto coil for power. So today we're cleaning out the rust from the gas tank, we've been using a small engine tank strapped to the hood. And we hope to get the magneto to give enough spark to start the engine. The owner also has to go over all the fluids and give it a lube job. If it all works he has a driveway to work on with it to get ready for winter. Then we move on to the D4 and an old Ford tractor as well. When my wife get home with the camera I'll try and post pictures.

Thanks,

Rob