I see a variety of pumps on the net, that look like they slip on to the pto shaft. Does this sound correct and if so, how would it be kept from just spinning?

I would tend to think that when you disengage the clutch, it will stop eventually, hence the reason some prefer "live" hydraulics because they might lack eye/hand coordination with their attachment or implement! JM

I have seen several methods of holding a "pump" on a live pto shaft. Bungee Cords, chains, ropes, even the hoses connecting the pumps to reservoir and discharge device. Depending upon what you are trying to accomplish, if you are talking HYDRAULIC implements or operating cylinders, I would NOT try a slip on and off pump! Those pressures and hot oil are unforgiving! Shortcuts are usually a trip to mechanic or worse - a medical facility!

We used a Prince pump made to slid on the PTO on a JD A to power a wood splitter for years. The pump we had, had a flat side with tapped holes. Used a piece of bar stock bolted to the pump that rested against the drawbar. It ran the 5 inch ram a bit faster, and lots more PSI than pump in the old put put A. We also plumber it so the valve was in reach of the operator holding the wood.

Traveling across country others had the drawbar pin pop out, of course ripping hoses. I never lost it, just do what is needed to keep the pin in place. Since it was moving from site to site no pressure in the system, no injuries.

On the Cat 22 I don't see a real problem. The pump is not directly tied to a towed implement. The pump is plumbed to the tank and valve, then the valve to implement. The same as the D2 at the play day. I try to set everything on the common Pioneers hydraulic coupling that if attached correctly with auto disconnect. But in dust and dirt many times don't disconnect unless they are removed and cleaned often. Nothing like being hooked to the same implement for 2 weeks and needing 2 hours to get hoses unhooked.

Even being semi retired and not wanting be discing for days at a time. If there is better quick connect coupling I am all ears.

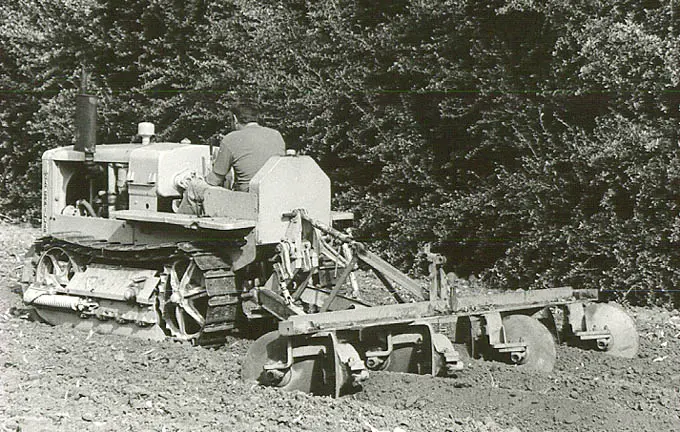

It is pretty hard to get live hydraulics on a 22. The generator hole could drive a small pump but very much torque could foul up the timing gear train. The inexpensive PTO pumps that I see on Amazon can be purchased for different gph and pressures. What I want it for is not continuous running of an implement, but to run a ram on my Killefer tool carrier or on my large (for a 22) tumblebug. I have a reservoir and valve from an old beegee set up from a D2. I am assuming that the old equipment rams take around 1000 to 1200 psi? Is that a safe guess? Speed of response is not as important as not having to get off of the tractor and yank on levers to raise or lower something. Yes, I am getting old and want things easier. Any advice is welcome. Thanks Grant.

Hi Grant, you could consider a belt-driven pump from the crankshaft

I have seen high speed roller chain driven hydraulic pump on Cat 22 from the crankshaft end. Roller chain is much easier to change than a belt. 'Oldironhabit" has that 22 last I knew. cts

I actually have a belt drive pump set up, but it is such a small pump (aircraft type) that I dont think it would move a piece of heavy iron. And yes I agree, a chain would be better than a belt. I have the book on 44 pumps, so I need to look up pressures and flow for the old style equipment. Grant.

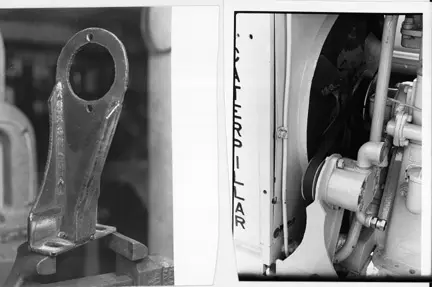

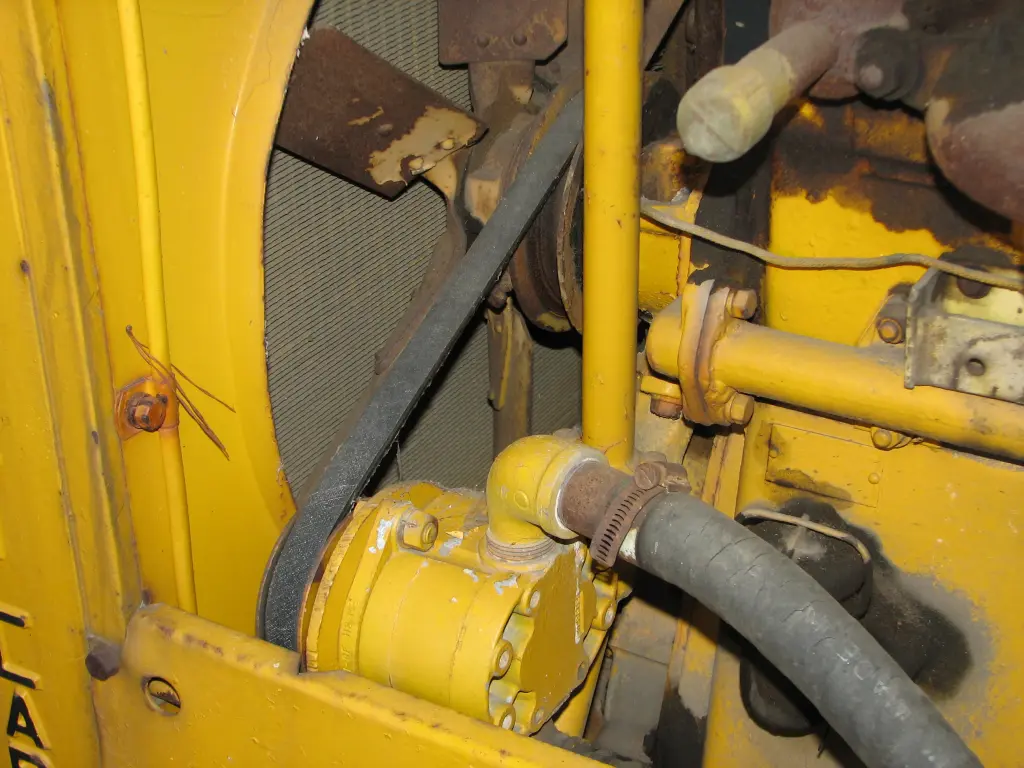

GrantJ, not necessarily suggesting you duplicate this for your own hydraulics. But back in the '80's I shopbuilt a 3-point hitch for my 22. That hitch unit won't apply to your situation, but to add hydraulics I fabricated a bracket to mount a belt driven hydraulic pump from the crankshaft pulley (like Neil suggested), with that same belt also driving the fan and water pump. Plumbed its output to the 3-point valve and a couple of remotes. Fabricated a seat back tank like a D2 for the hydraulic reservoir.

Catspotter, that's quite the shop-built attachment. Did you make use of any off the shelf parts for the hitch assembly? Some of those parts look cast which must a testament to the quality of your fabrication. What's that tube for that appears to be emanating from the front of the exhaust manifold? That tractor must have been a joy to use in the vege patch and avoiding the compaction of wheels would have been a great bonus too

Grant: Sorry about my post; I had to read your question over! LOL. JM