[quote="Mike Meyer"]Nice work on your motor Ray, how much do the new babbitt bearings cost in the USA to pour and machine? My 22 parts book says that oil pump spring is P/N OL1142, and I'd suggest you contact your Cat. Dealer first because it is weird what parts they sometimes have for the old girls.

regards

Mike[/quote]

Mike,

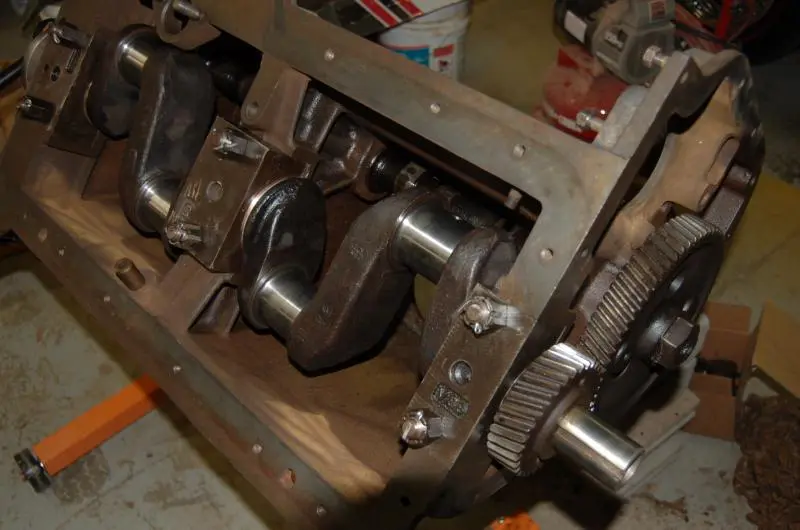

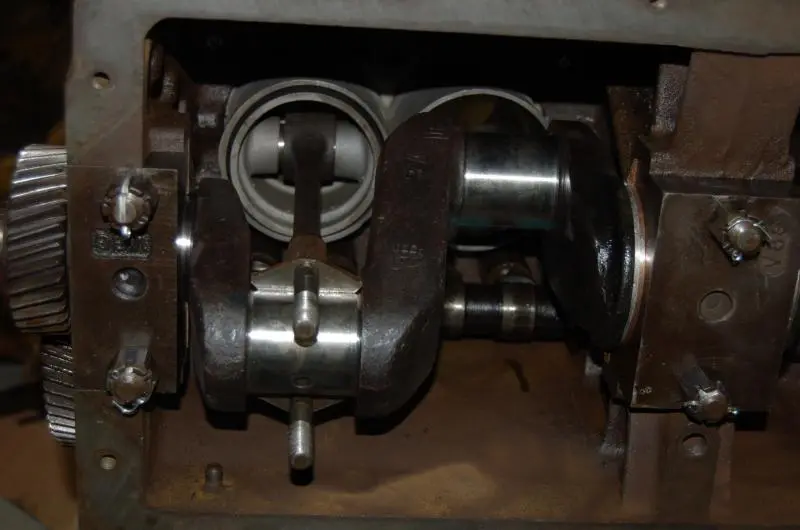

I looked around at a couple options for doing the re-babbitting. One company in Syracuse, NY said I should only give them my bearing shells and drawings of what I wanted them to do and they would make the bearings to my drawings. If they didn't work it would be my problem since they built to my drawings. No way I would work with them. Then I called Ziggy at Babbitt Pot in Ft. Edward, NY. He said to bring him the block, rods, and shells. He would line bore the block, grind the crank, pour the babbitts for the mains and rod bearings, then assemble the crank into the block. Total cost was $1,700. I may have been able to find a lower cost shop, but I felt very comfortable with Ziggy. He came well recommended by other club members. Ray

[quote="

[email protected]"]Mike,

I looked around at a couple options for doing the re-babbitting. One company in Syracuse, NY said I should only give them my bearing shells and drawings of what I wanted them to do and they would make the bearings to my drawings. If they didn't work it would be my problem since they built to my drawings. No way I would work with them. Then I called Ziggy at Babbitt Pot in Ft. Edward, NY. He said to bring him the block, rods, and shells. He would line bore the block, grind the crank, pour the babbitts for the mains and rod bearings, then assemble the crank into the block. Total cost was $1,700. I may have been able to find a lower cost shop, but I felt very comfortable with Ziggy. He came well recommended by other club members. Ray[/quote]

That is very reasonable I think, I paid $550 to have my 2 Ton crank machined, and another $800 to have the bearings poured and block line bored, but that was 2 years ago and I hunted high and low for a good tradesman who didn't charge like a Lawyer, and it took the old fella a year to get around to finishing the job, while a local "Expert" white metal bearing guy quoted me over $2,000 just to do the bearings!

I have a local guy setting himself up as a Machine Shop and has all the right machines and presses including 3 different lathes and just bought himself (or more accurately, his Dad just bought him😖mokin😊a new CNC lathe for over $100,000 I believe, yet twice in the past few months I've called in with some small jobs and each time he is pretty quiet work wise, but says, "oh Mike, I'm a bit worried I might break something on my lathe machining those front idlers you built up with weld, and I charge $75 a hour and if I break something I'll be charging you for those broken tool bits too".

Needless to say Ray I continue to take my business to a good old Fitter and Turner who has both the brains and ability to get the job done in a timely and cost effective manner, but I am looking out for a old metal lathe so I can start making simple things like new bronze bearings, or turn up worn rollers I've rebuilt, folks not much smarter than me tell me it isn't that hard to learn how to use a metal lathe if you go quietly and slowly, and I remember making a pretty nice 5 foot tall wood lamp for my Mom on a wood lathe at High School back in the 1970's as a 14 year old, so I figure it can't be tool much different!😆

regards

Mike