Must be some serious wear on the dogs to jump out without the moldboard even connected up. Or is it possible there is a pinion binding in the gearbox in front of the cab?

pictures?

Thinking about what you describe...........The blade moves up and down if you hold the lever engaged, but it still clacks regularly as it moves up or down? Or just up?

Sounds like a bad tooth on a gear in front of the control box. There are 2 sets of bevel gears which could be the problem. Maybe a piece of tooth jammed in between two teeth.

[quote="ccjersey"]Must be some serious wear on the dogs to jump out without the moldboard even connected up. Or is it possible there is a pinion binding in the gearbox in front of the cab?

pictures?

Thinking about what you describe...........The blade moves up and down if you hold the lever engaged, but it still clacks regularly as it moves up or down? Or just up?

Sounds like a bad tooth on a gear in front of the control box. There are 2 sets of bevel gears which could be the problem. Maybe a piece of tooth jammed in between two teeth.[/quote]

Yes it makes the noise up and down. I was thinking the same thing about a bad tooth on the gear. I did move the connecting arm up one adjustment hole to give me a new set of teeth on the gear. That didn't help. Is it a big deal to take that gear housing in front of the cab off to look at those gears? I think I am out of options except for that.

You have a wonderful day. Best wishes. Deas Plant.

Hi, Longshot.

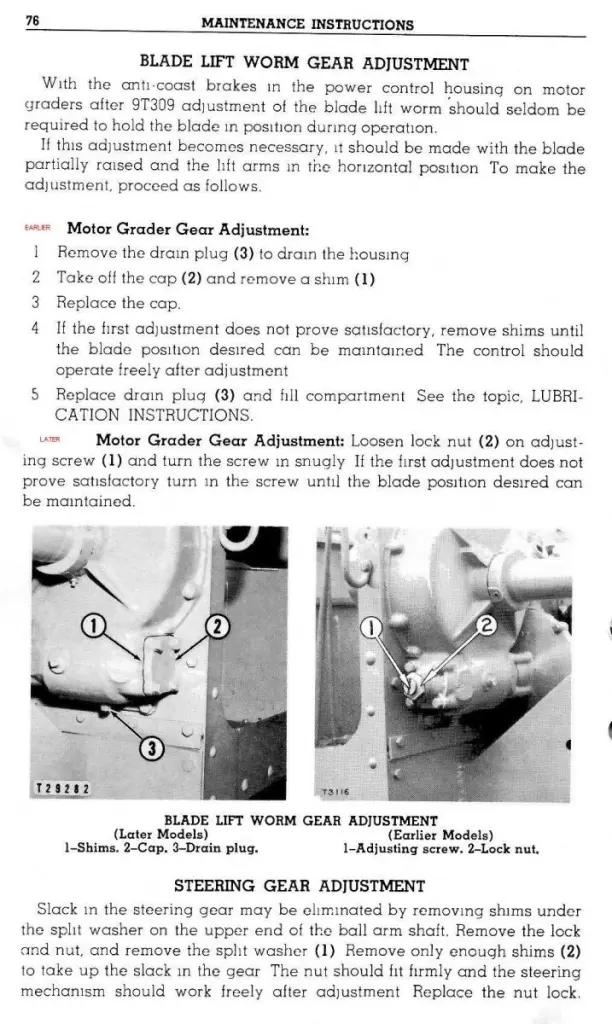

Check to see if your machine has a screw adjustment on the worm drive pinion under the main blade lift gear on the front of the cab. If it does, put very light up pressure on the blade lift and adjust that set screw until it is just starting to come tight then do up the lock nut and try it. DO NOT try to tighten this adjustment up too tight as that will be just as bad as having it too loose.

If that doesn't cure your problem, you are most likely looking at a broken tooth somewhere in the smaller gears. If that is the case, I would drain all the oil from these cases and check the oil for any metal fragments. Then wash the cases out with diesel fuel. catch the washings and check them for same.

Hope this helps.

Hi longshot,

welcome to the BB,

Deas has given you the first thing I would check for the kicking problem in both directions of the blade lift control lever.

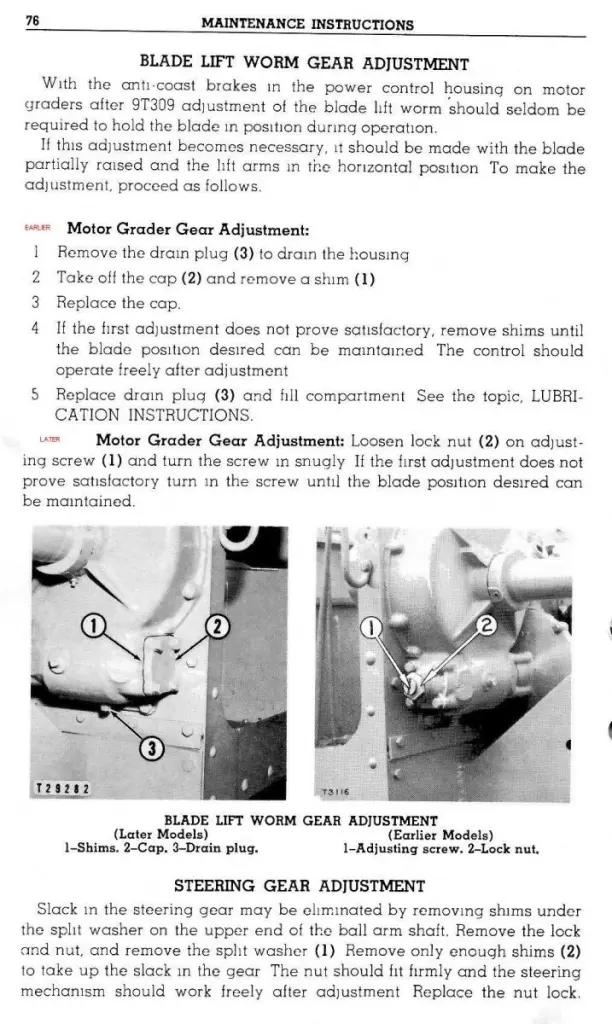

As you did not give a Serial # there are two types of adjustment for this worm.

The early one has no adjust screw and so is adjusted with shims under the end cover.

Set the lift arms at horizontal.

Drain the worm box of oil and remove the end cover. Take out any shims under the cover. Refit the cover without the shims and gently seat the cover with the 4 bolts tightened lightly and evenly.

Measure the gap and subtract 0.003" and fit shims of this dimension = 0.003" pre-load.

Replace drain plug and refill with oil. Retry and adjust to suit.

If this adjustment is on the loose side the blade will drift during operation on a long grading run.

Hope this helps.

I have scanned from a 212 grader grey Operation and Maintenance Instructions the two proceedures.

Hope this helps.

Cheers,

Eddie B.