Reply to TIREDDOZER:

It's a d8 2u ser# 12593

Hi Tireddozer,

have you had the side cover off the injection pump.

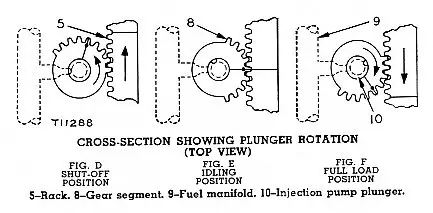

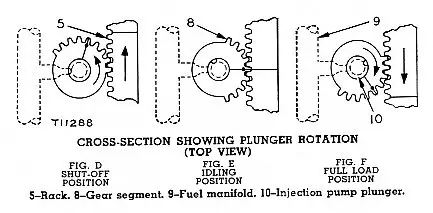

In there you will see the rack which in turn moves all the quadrant gears on the individual pump plungers.

There are timing lines grooved into the rack and a similar line on the plunger gear--check they are timed correctly.

If they are correct, then swap number one pump with say number two and see if the problem follows the swap.

If it does, then the problem is in the previous number one pump.

Sometimes people force a stuck rack that in actual fact is a stuck plunger. This action can turn the gear out of time to the Factory set position on the plunger. This then sets the plunger to either inject more or less fuel than specification--depending on which direction the rack was forced.

For future reference only:-

Usually a stuck plunger will be stuck in the upstroke position, if the engine has been turned--before attempting to move the stuck lifter/plunger be careful that the cam lobe is facing down or you will be forcing against it and may break the brittle lifter yoke.

Best way to loosen a stuck pump plunger is to spray in some loose juice and very gently lever the lifter/plunger up and down until it is returning to contact the cam freely by the return spring on the plunger.

A turned plunger gear can be reset against a known good pump on a Fuel Pump Test bench by the volumes delivered per a series of rack settings, but it usually easier and cheaper to fit a good used pump.

Start with these checks and report back so we can help you thru this a step at a time.

Hope this helps.

Cheers,

Eddie B.