I would have to say the short pto shaft has to go, too sharp of an angle, I would just have one sliding shaft from the gear box to the pto coupler. When that baby is under load on a turn she'll be a knockin and a bangin. If you can find a shaft that will fit the square stock and run to the pto coupling that should work fine.

Yup, that's my biggest fear. I hadn't thought of just lengthening the front part of that existing shaft, we will consider that.

Thanks,

Jordan

Hi having used trailing pto gear for years (ac rollbalers and side rakes etc )the drawbar pinhole is 14 inches from the end of pto on the tractor and it wiil turn well then the 5u D2had an extension that came with the pto to make turning point right

Cheers

You have a wonderful day. Best wishes. Deas Plant.

Hi, JStandle.

I think you will find that set-up will work just fine even when running during quite sharp turns if you extend your crawler drawbar and shorten the mower drawbar so that the ball hitch pivot point is exactly 1/2-way between those first 2 universal joints. I did 5 years working on broad acre wheat farms in my miss-spent youth, harvesting with drawn, PTO-powered harvesters and we always set them up so the hitch pin was exactly mid-way between those first 2 universal joints and the PTO shaft was as close to flat as possible.

We were harvesting at 6 MPH and you could turn so sharp that the far end of the harvester was 'ackshully' going backwards during the turn and never even a slight chatter out of the PTO shaft. It appears that the exact length of either the tractor drawbar or the trailed implement drawbar does not matter so long as the pivot point between the 2 is exactly 1/2-way between those first 2 universals.

Just my 0.02.

Hi that would be right Deas the machine that we used were never altered from brand new and as you said the hitch point is halfway between the universal

Cheers

Peter

Hi that would be right Deas the machine that we used were never altered from brand new and as you said the hitch point is halfway between the universal

Cheers

Peter

The only thing I would add to the other comments would be the oil in the actual pto unit. If it shares oil with the bevel gear compartment then disregard my thought. The older D4 pto units had their own separate oil sump, so in a higher horsepower tractor the oil overheats and the box can fail catastrophically.

Just make sure the oil in the box is adequate and check the temperatures after you mow a bit.

Happy mowing

BP.

[quote="Deas Plant."]Hi, JStandle.

I think you will find that set-up will work just fine even when running during quite sharp turns if you extend your crawler drawbar and shorten the mower drawbar so that the ball hitch pivot point is exactly 1/2-way between those first 2 universal joints. I did 5 years working on broad acre wheat farms in my miss-spent youth, harvesting with drawn, PTO-powered harvesters and we always set them up so the hitch pin was exactly mid-way between those first 2 universal joints and the PTO shaft was as close to flat as possible.

We were harvesting at 6 MPH and you could turn so sharp that the far end of the harvester was 'ackshully' going backwards during the turn and never even a slight chatter out of the PTO shaft. It appears that the exact length of either the tractor drawbar or the trailed implement drawbar does not matter so long as the pivot point between the 2 is exactly 1/2-way between those first 2 universals.

Just my 0.02.[/quote]

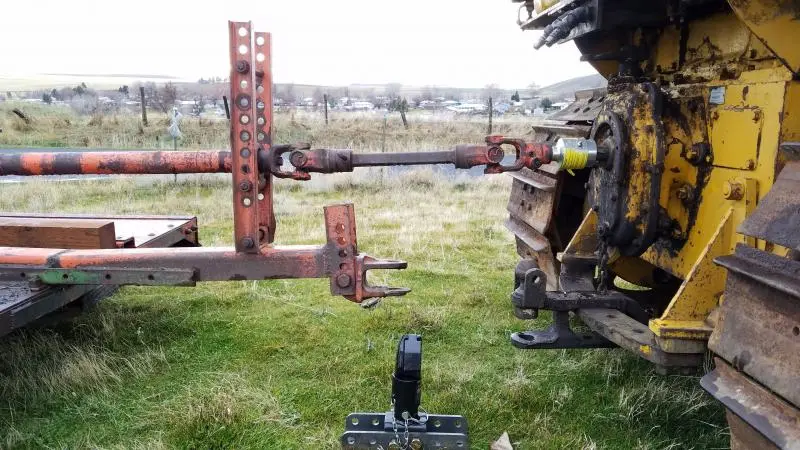

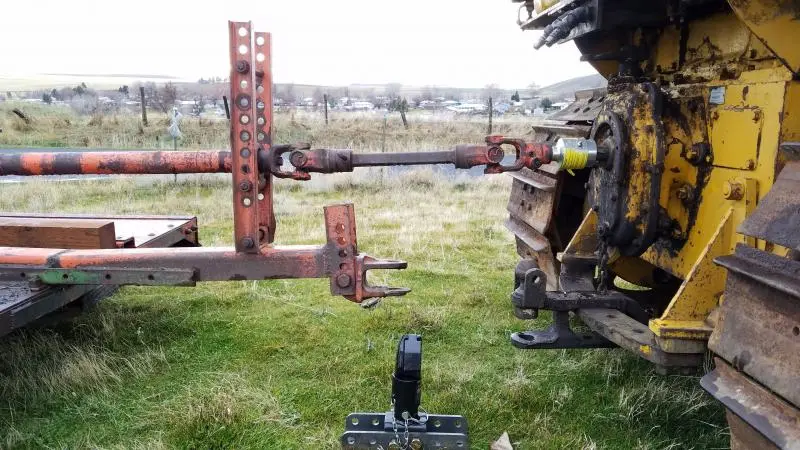

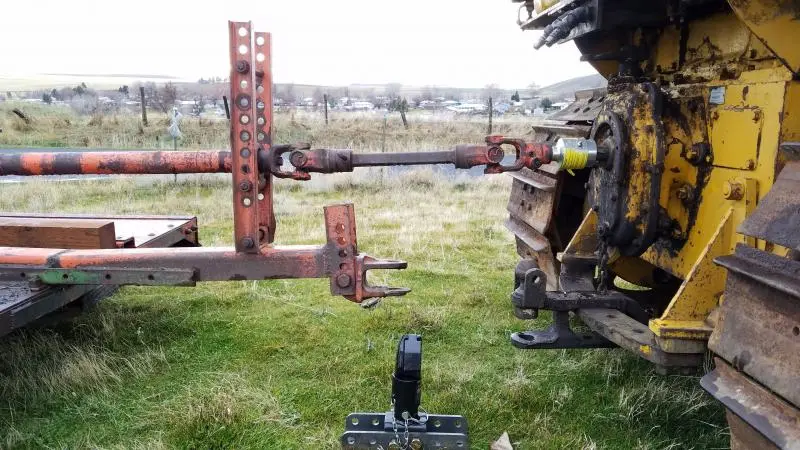

Thanks for that info! Now knowing that I can see a mistake we have made, the picture below is how things looked before I lengthened the mower tongue to reach the drawbar. It WAS roughly half-way between those joints. Sounds like I need to bolt on an extension to the drawbar hitch instead and put the mower coupler back where it was.

[attachment=52529]D4D rotary 3.jpg[/attachment]

[quote="Bruce P"]The only thing I would add to the other comments would be the oil in the actual pto unit. If it shares oil with the bevel gear compartment then disregard my thought. The older D4 pto units had their own separate oil sump, so in a higher horsepower tractor the oil overheats and the box can fail catastrophically.

Just make sure the oil in the box is adequate and check the temperatures after you mow a bit.

[/quote]

This PTO unit has it's own reservoir so that is good to know. Would going to a full synthetic gear oil help in this case?

Thanks!

Jordan

[quote="Deas Plant."]Hi, JStandle.

I think you will find that set-up will work just fine even when running during quite sharp turns if you extend your crawler drawbar and shorten the mower drawbar so that the ball hitch pivot point is exactly 1/2-way between those first 2 universal joints. I did 5 years working on broad acre wheat farms in my miss-spent youth, harvesting with drawn, PTO-powered harvesters and we always set them up so the hitch pin was exactly mid-way between those first 2 universal joints and the PTO shaft was as close to flat as possible.

We were harvesting at 6 MPH and you could turn so sharp that the far end of the harvester was 'ackshully' going backwards during the turn and never even a slight chatter out of the PTO shaft. It appears that the exact length of either the tractor drawbar or the trailed implement drawbar does not matter so long as the pivot point between the 2 is exactly 1/2-way between those first 2 universals.

Just my 0.02.[/quote]

Thanks for that info! Now knowing that I can see a mistake we have made, the picture below is how things looked before I lengthened the mower tongue to reach the drawbar. It WAS roughly half-way between those joints. Sounds like I need to bolt on an extension to the drawbar hitch instead and put the mower coupler back where it was.

[attachment=52529]D4D rotary 3.jpg[/attachment]

[quote="Bruce P"]The only thing I would add to the other comments would be the oil in the actual pto unit. If it shares oil with the bevel gear compartment then disregard my thought. The older D4 pto units had their own separate oil sump, so in a higher horsepower tractor the oil overheats and the box can fail catastrophically.

Just make sure the oil in the box is adequate and check the temperatures after you mow a bit.

[/quote]

This PTO unit has it's own reservoir so that is good to know. Would going to a full synthetic gear oil help in this case?

Thanks!

Jordan