Most of that sounds pretty normal. I only do the crank to oil pressure start after unit has been sitting for a long time.

Hate to ask and get the oil debate going but what weight oil are you using. A modern straight weight SAE40 would be a closer match to the old SAE30 for that machine in your climate.

I am using SAE40 as you recommended to me several years ago in every sump. Real foolproof system. Same in D7 47A.

To be current that would be SAE40 engine oil and TDTO (TO-4) SAE40 in the drive train. Otherwise all sounds good to me.

I am using heavy duty diesel engine oil sae40 in all areas. My omi calls for sae30 superior lubricant series 3 in all oil bearing compartments from engine to ccu, which I thought translated into sae40 today. Is this wrong?

The later TDTO (transmission drive train oils),, first TO-2 spec. now TO-4 are formulated for friction disc operation where it was determined that motor oils are to slick with all the engine oil additives.

Hi cab, I know that the TDTO oil is the way to go but I also know you don’t operate your ‘dozers full time and you are careful to operate them properly so it is not necessary to change to drive-train oil until a scheduled oil change. When Caterpillar advised me to change to drive-train oil back in the 90’s I decided that any advantage gained would not be worth the risk of one of my operators mistakenly adding drive-train oil to the engine. I never had an oil related transmission failure.

Old Magnet is correct, it is not necessary to wait for full oil pressure before fire-up.

I suggest letting the tractor cool down at high idle with the oil pressure in the green and then a shorter period of time at low idle before shut down.

Happy 'dozing,

Craig

Is the engine idling to low? This can indicate a low reading when the engine is at op temp and at an under rated idle rpm.

Hi Cab,

ROME/KG makes a good point, often overlooked, with his comment about an engine idling at an under spec low idle speed affecting the low idle oil pressure reading.

Edit as per OM's prompt :- Low Idle Speed for the early 36A is 450 +/- 30 rpm My Rack book has a Temporary Chart for later s/no's that says 450 +/-10 rpm so it is not the final rpm as per OM's correction below. The 30 rpm variance is to allow for parasitic loads like thick oils in a cold engine, clutch drag, generator charging etc.

Silly me picked the Gen Set LI 😊

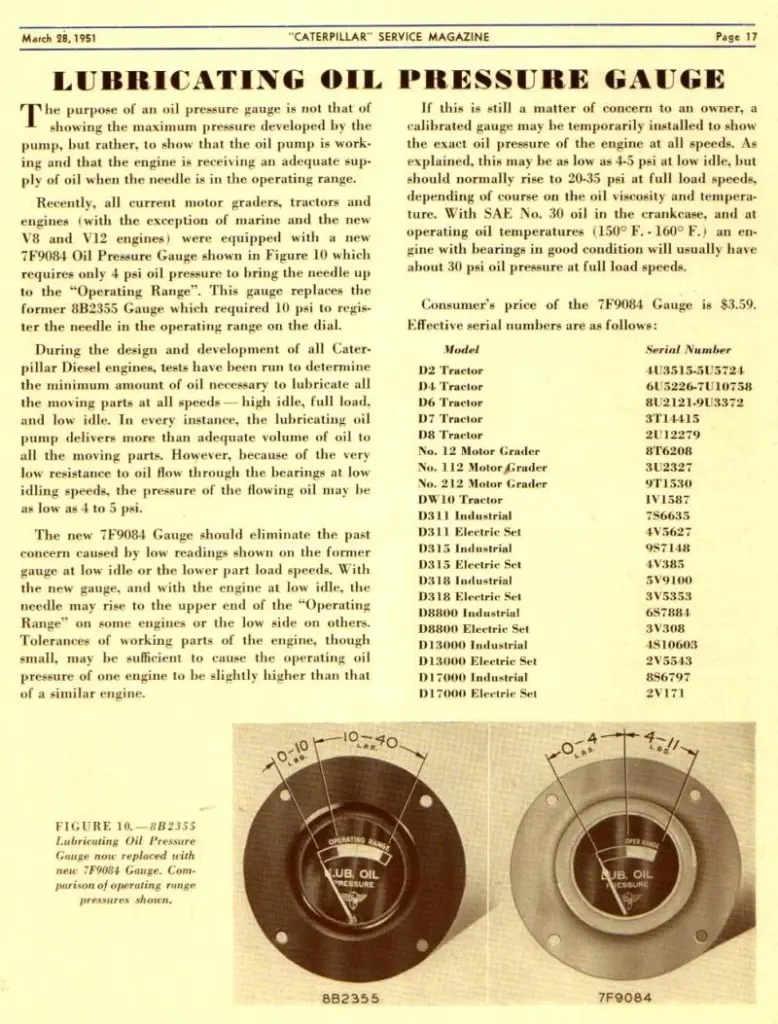

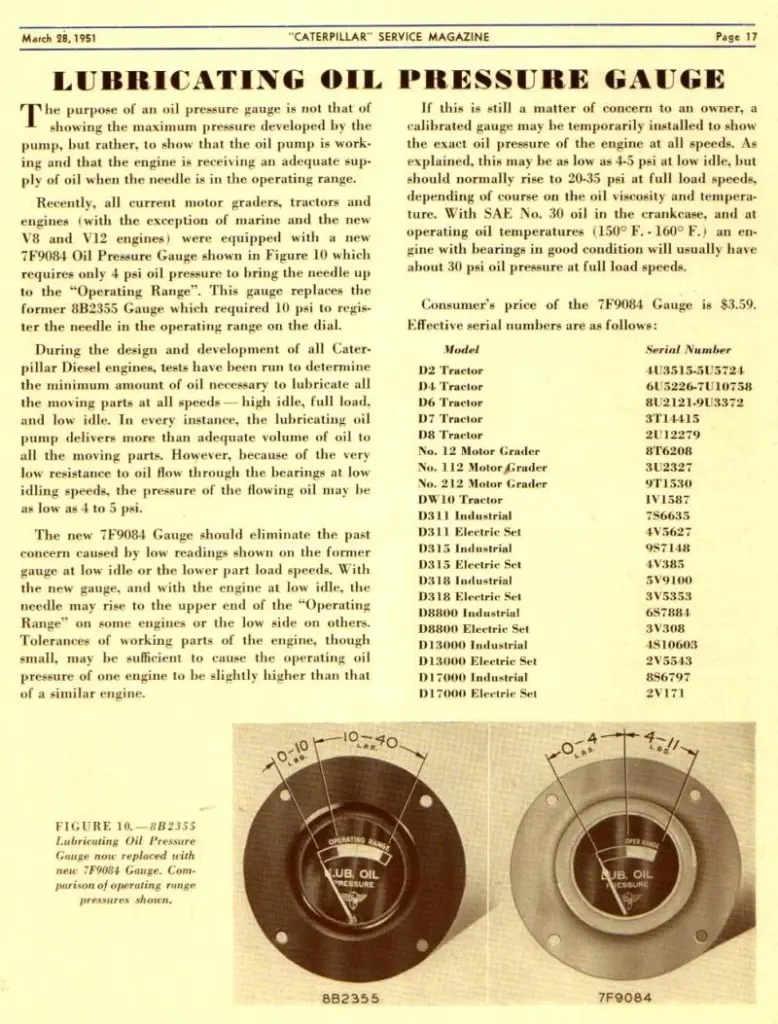

Depending on which Part No gauge you have the reading can appear different.

A true test would be with a known accurate gauge.

These old low stressed engines have large bearing areas and so do not need to use high oil pressures to keep the components apart. They use low oil pressure with high flow rates.

Cheers,

Eddie B.

Hi edb,

My 1974 Rack Setting printing says 450 rpm or 475+/-30 rpm depending on s/n.

650 rpm +/- 50 rpm Decelerator setting if it has that feature.