This is the way I do it. for a 3T . A 17A will be slightly different being even fire rather than the 3T odd fire engine.

Fit the magneto with out reference to any timing marks.

With the plugs removed Fit the spark plug leads to the plugs and ground them in a position you can see the spark.

Turn the engine over slowly with the hand crank watching for the spark while listening for the impulse to trip.

Number one plug will fire then no 2 then 2 impulse clicks with no spark.

Turn the engine as slow as you can until you hear and see no 1 plug spark, stop turning engine immediately.

Remove the magneto from engine with out turning the magneto.

With your finger over the no 1 spark plug hole turn the engine with the crank handle until you feel compression .

With the fly wheel cover plate removed find TDC mark and continue to turn engine till TDC mark lines up with line in centre of window.

Now refit magneto with out turning anything.

If the impulse trips at TDC this should give the correct timing advance with engine running.

Hope this helps and you can understand what I am trying to say.

Andrew.K.

[quote="Andrew"]This is the way I do it. for a 3T . A 17A will be slightly different being even fire rather than the 3T odd fire engine.

Fit the magneto with out reference to any timing marks.

With the plugs removed Fit the spark plug leads to the plugs and ground them in a position you can see the spark.

Turn the engine over slowly with the hand crank watching for the spark while listening for the impulse to trip.

Number one plug will fire then no 2 then 2 impulse clicks with no spark.

Turn the engine as slow as you can until you hear and see no 1 plug spark, stop turning engine immediately.

Remove the magneto from engine with out turning the magneto.

With your finger over the no 1 spark plug hole turn the engine with the crank handle until you feel compression .

With the fly wheel cover plate removed find TDC mark and continue to turn engine till TDC mark lines up with line in centre of window.

Now refit magneto with out turning anything.

If the impulse trips at TDC this should give the correct timing advance with engine running.

Hope this helps and you can understand what I am trying to say.

Andrew.K.[/quote]

Thanks. I eventually got it but will try your way next time. The Operating Manual procedure works but there are a couple key steps left out like having to roll the flywheel back a little to get the magneto and trunion to sync.

The good news here is I found out one of my plugs was grounded out somewhere and wasn't firing at all, this pony motor has so much more power now. I only lost 3 screws and ripped one wire off in the process. And I need to order 3 gaskets tomorrow. Hey at least it is running again and we can keep bringing fill in. Only 120,000 more cubic yards to go.

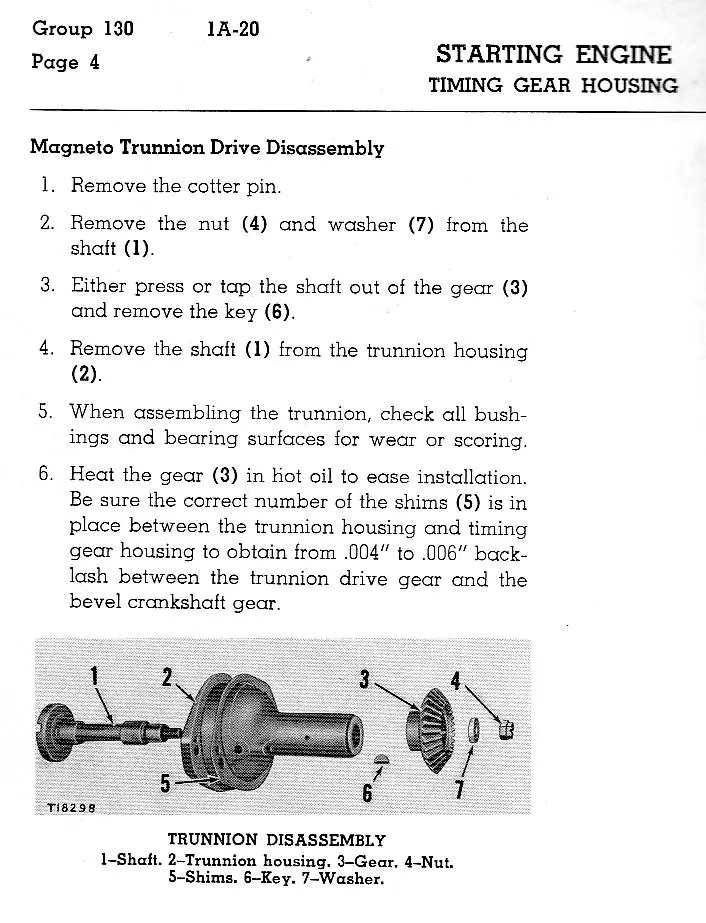

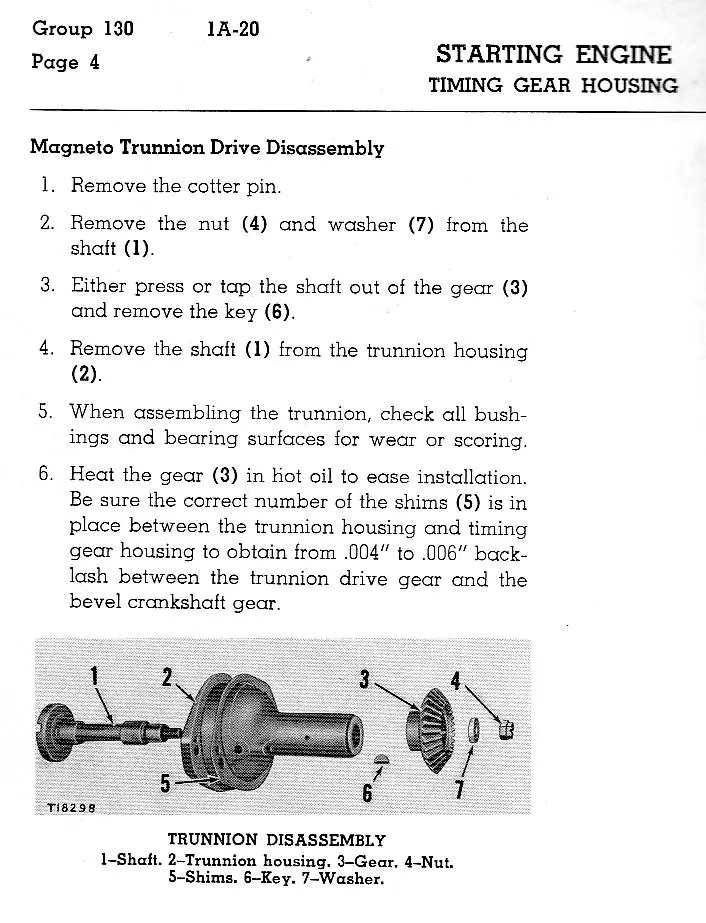

Related question. When I was doing all of this I tore up all the gaskets. I went order replacements from Cat today and they couldn't find a part number for the thin metal shim that does between the trunion and the block. The parts book says it is 8F6801.

Is this shim really needed and if so does anyone know the new part number? Whenever I work on something to I try to get it back to a state where it won't leak oil and is factory correct so if I need it I'd like to get it back in there.

reidrhollander.

Just to clarify, you request info for a 3T . the serial no you quoted is for a 17A. These machines are different in that area.

Which one is it??

There are only 2 bolts holding the magneto on , so unsure how you can loose 3 screws.

Magneto generally bolts strait on without any gasget or shims .Without doing a parts book search I am unsure about the metal shim you mention. Other B.B.ers may know what you require.

Andrew.K.

[quote="Andrew"]reidrhollander.

Just to clarify, you request info for a 3T . the serial no you quoted is for a 17A. These machines are different in that area.

Which one is it??

There are only 2 bolts holding the magneto on , so unsure how you can loose 3 screws.

Magneto generally bolts strait on without any gasget or shims .Without doing a parts book search I am unsure about the metal shim you mention. Other B.B.ers may know what you require.

Andrew.K.[/quote]

It is for a 17A, I thought the pony motor was called a 3T. What is the designation for the pony motor?

Yes, there are 2 bolts holding the magneto on, and 4 screws holding the cap, and two more screws holding the plate under the rotor, and 4 bolts holding the cover on the flywheel. I have it running now but would like to put all the gaskets in that fell apart when taking it apart. The shim is a very thin piece of metal that goes between the block and trunion and is in the parts book but Cat says it is discontinued and can't find a replacement part number. It may not be needed but I figure they put it there for a reason when it was new so it should go back in.

reidrhollander.

3T is the tractor model that precedes the 17A series.Much the same tractors with the main difference perhaps being the pilot motor.

I am not aware of any particular pilot motor designation except maybe the tractor series. ie;3T or 17A or whatever.

These are commonly called side mount or vertical pilot motors. As different to horizontal pilot motors as used on D2 D4 D6

and some others.

Is the shim you refer to between the magneto and the engine??

Hopefully others will know about the shim you refer to.

Also what part of the world are you from.

A. K.

[quote="Andrew"]reidrhollander.

3T is the tractor model that precedes the 17A series.Much the same tractors with the main difference perhaps being the pilot motor.

I am not aware of any particular pilot motor designation except maybe the tractor series. ie;3T or 17A or whatever.

These are commonly called side mount or vertical pilot motors. As different to horizontal pilot motors as used on D2 D4 D6

and some others.

Is the shim you refer to between the magneto and the engine??

Hopefully others will know about the shim you refer to.

Also what part of the world are you from.

A. K.[/quote]

It goes between the block and the trunnion.

Hi Reid,

the shims are to adjust the trunion drive housing up and down so as to give a Backlash Clearance between the two bevel gears of 0.004" and 0.006".

Hope this helps.

Cheers,

Eddie B.

[quote="edb"]Hi Reid,

the shims are to adjust the trunion drive housing up and down so as to give a Backlash Clearance between the two bevel gears of 0.004" and 0.006".

Hope this helps.

Cheers,

Eddie B.[/quote]

Thanks! That is an interesting page, I have the parts, operator, and service manuals and didn't see that anywhere. Although my parts book does give a part number. Since Cat can't seem to find the part # and the old one is long gone I guess I will have to run without it. It is really going to bug me having a part missing like that and knowing that it isn't set up right.

Thanks for the info though.