In order for the pump to actually pump track roller grease the lever needs to be held, that means the cable would be hooked in such a way to keep the grease from recycling. This was meant to quickly release pressure against the track roller seals.

In operation one would pump very easy feeling for resistance, then let go of the lever and continue placing the pump lever down. Then take a screwdriver or some pointed object and release pressure in the roller bearing cage by depressing the button in the grease zerk(?).

(Prob more information than you wanted)

These should help.....

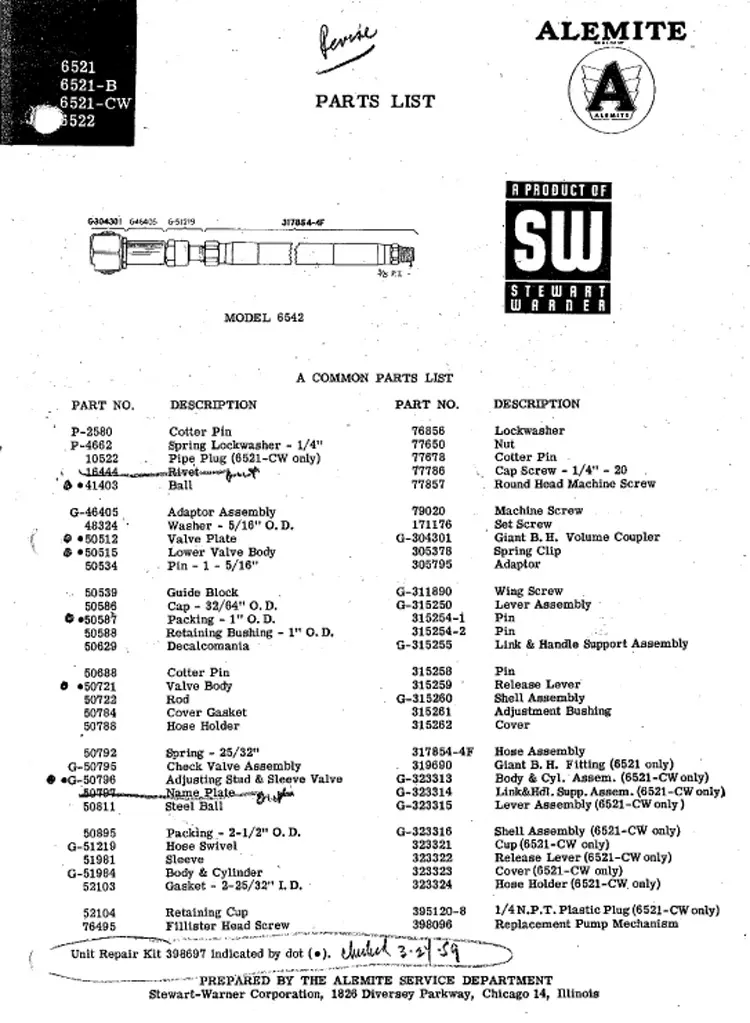

[attachment=63539]alemite doc.pdf[/attachment]

Cats Forever

Now if we can find a way to get this into the Technical Library and an easy way to locate it once it is there.

If the document contributors will email the pdf files to [email protected] we will include them in the library, suitably indexed and report back here.

if you click save on my pdf you can save it where ever you want it .

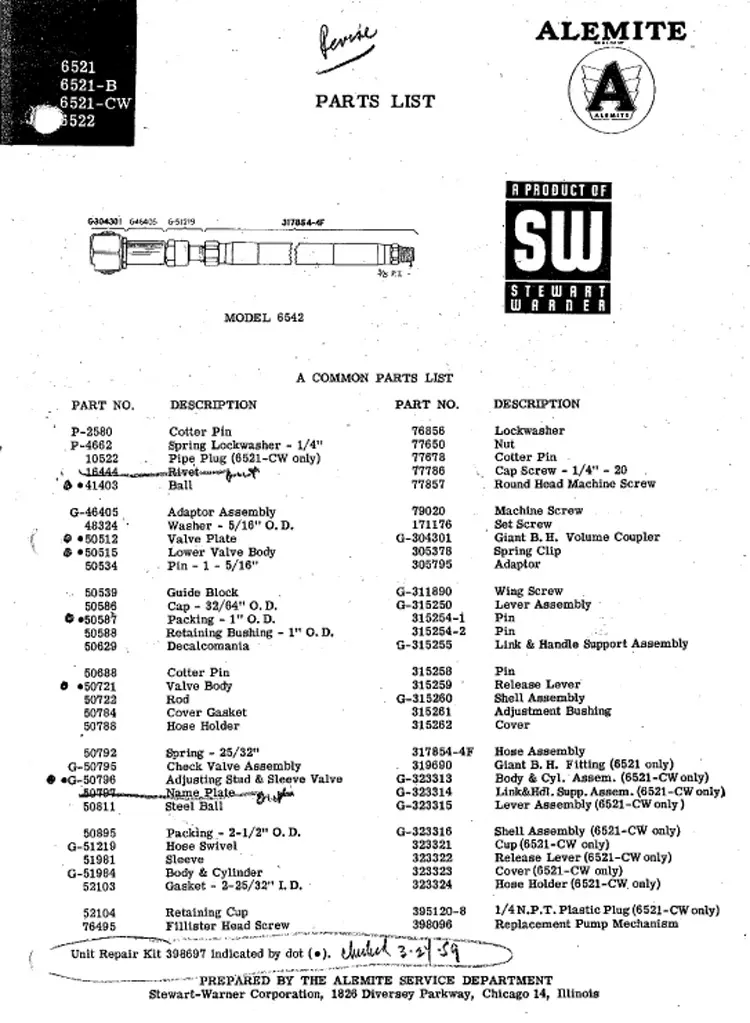

Thanks Bruce, your document is now published in the library under Operators instructions \ Alemite.